APM belt speed real-time monitoring device and method

A belt speed, real-time monitoring technology, applied in the field of integrated circuit manufacturing, can solve the problems of affecting film thickness, abnormal belt speed, easy slipping, etc., and achieve the effect of avoiding multiple conversions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

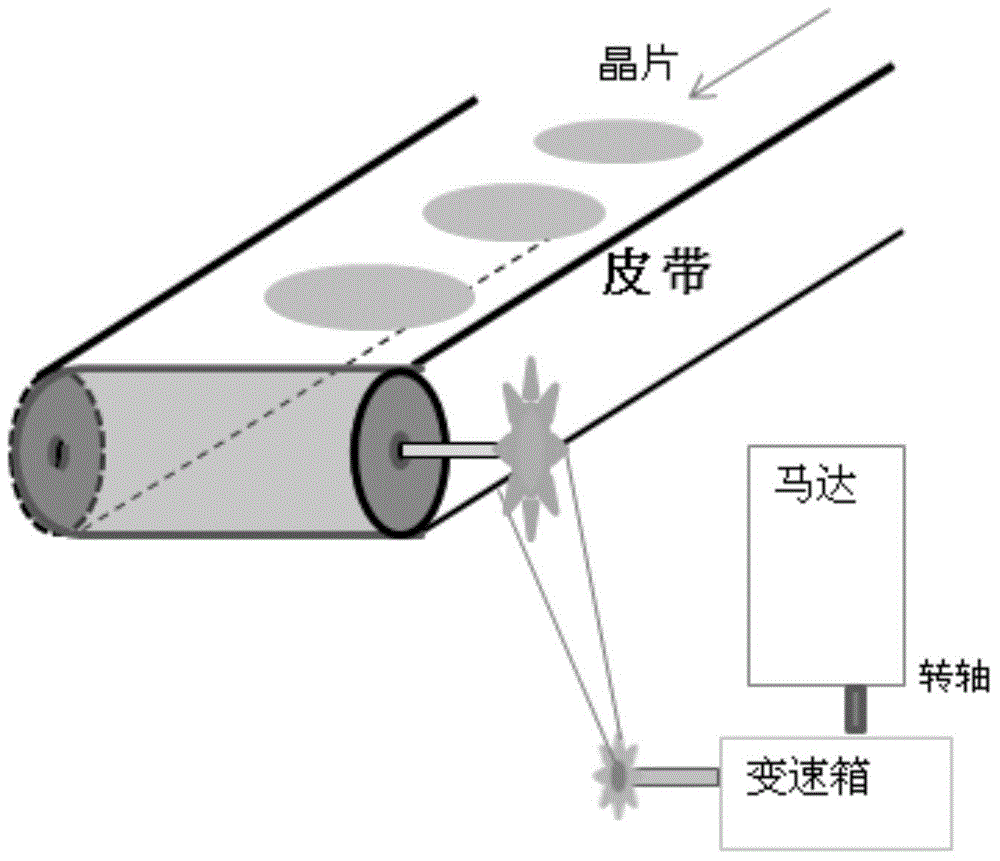

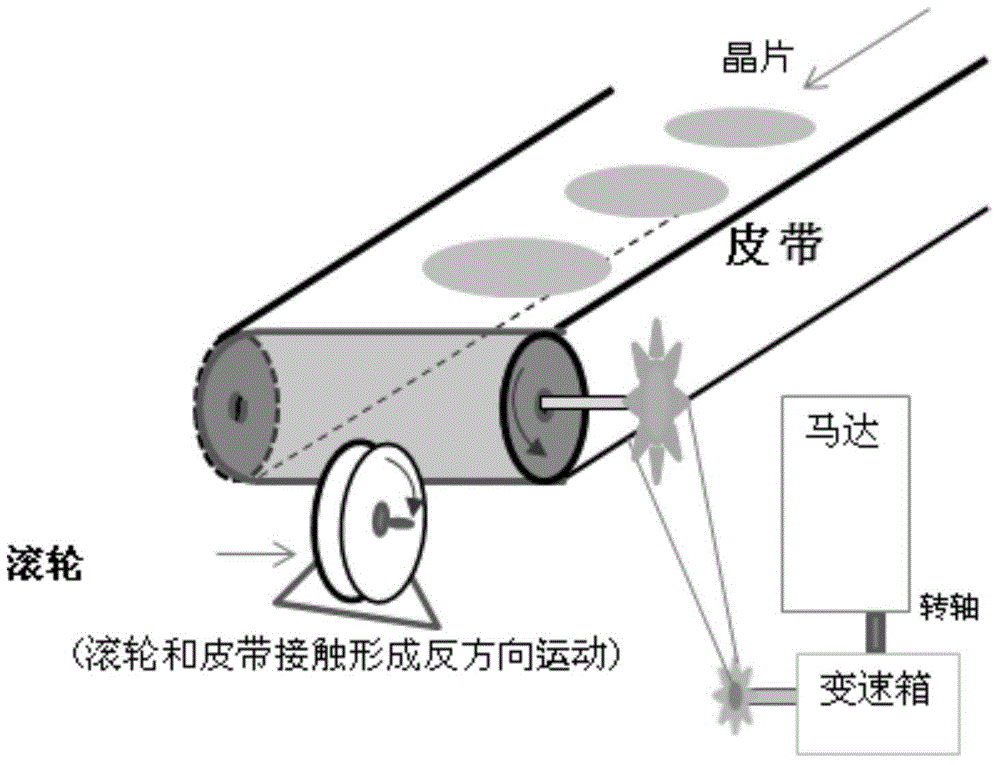

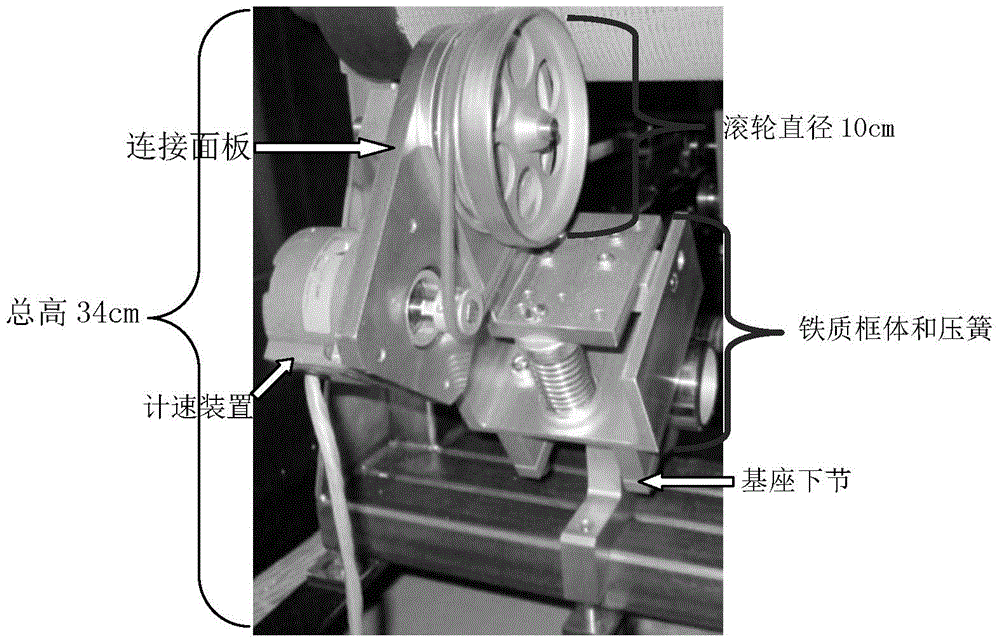

[0016] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the accompanying drawings, the details are as follows:

[0017] The present invention adopts the contact roller method to monitor the belt speed of APM in real time, and its working principle is as follows: figure 2 As shown, a metal roller is installed under the belt (it must be made of metal to prevent the surface of the roller from being scalded), the roller and the belt are in direct contact (the length of the contact surface must be more than 2 cm to ensure that the roller does not slip), and the distance between the roller and the belt maintain a certain pressure.

[0018] When the belt is running, the belt drives the rollers to rotate synchronously in the opposite direction to the belt, and the two form a real-time relative motion system, and the actual speed of the belt is transmitted to the rollers in real time....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com