Testing device for static/dynamic metal shearing behavior

A testing device and static shearing technology, applied in the field of measurement, can solve the problems of inaccurate data, increase production cost, and troublesome cap sample preparation, and achieve the effects of reducing cost, simplifying preparation, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the drawings and embodiments.

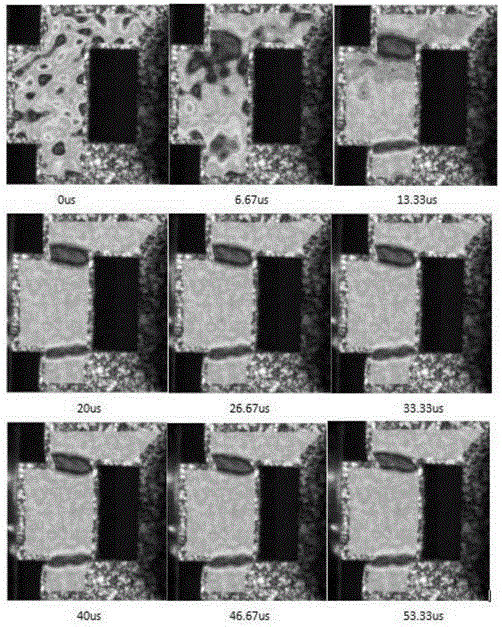

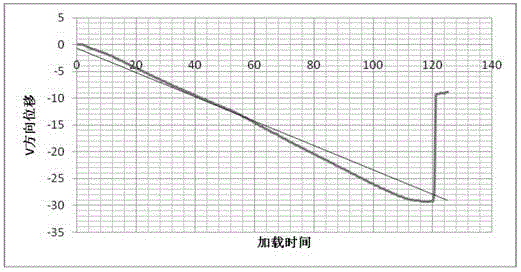

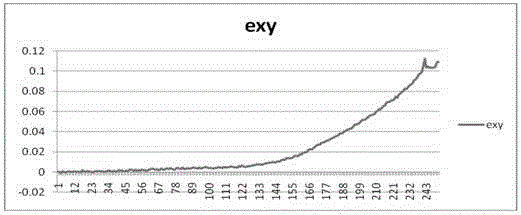

[0039] The invention provides a testing device for the dynamic and static shearing behavior of metals. The core idea is that the prepared convex sample is suitable for both dynamic and static shearing behavior testing, and speckles are made on the surface of the convex sample. , Use digital image correlation method to calculate the collected data to obtain sample deformation strain field related data, which can include deformation strain field cloud image and shear strain rate cloud image, as well as displacement time curve and strain time curve; this method can be directly observed The whole process of sample cutting area and shear deformation, and suitable for dynamic and static shear behavior testing.

[0040] The testing device for metal dynamic and static shearing behavior includes a loading device, a sample, an image acquisition device, and a data processing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com