Machine vision illumination light source and operating method of machine vision illumination light source

A lighting source and machine vision technology, applied in the direction of light source, electric light source, lighting device, etc., can solve the problems of poor image acquisition effect, inability to change the light source, and poor image quality, so as to increase the uniformity of illumination and improve the detection efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as Figure 1-2 As shown, it is a structural schematic diagram of the machine vision lighting source of the present invention, including a base plate 4, a housing 18 fitted with the base plate 4, and a transmission component installed on the base plate, and the transmission component includes a rotating part 100 and a transmission part 200.

[0042] Wherein, the rotating part 100 includes a knob 1, and a bearing 2 and a large helical gear 3 are sequentially arranged under the knob 1, and the large helical gear 3 cooperates with the bearing 2; wherein, the transmission part 200 includes a small helical gear 5, and the small helical gear 5 is connected to the The large helical gear 3 is meshed with the small helical gear 5. A screw 6 is installed on the screw 6. A slider 8 is installed on the screw 6. Each slider 8 is connected with four pulleys 9 by screws 10. The slider 8 Installed in cooperation with the slide rail 7 , the slide block 8 is connected with th...

Embodiment 2

[0047] This embodiment is a machine vision lighting source, which specifically includes the following steps:

[0048] S1. Fix the machine vision lighting source of the present invention on the image acquisition end of the machine vision detection system, so that the axis of the camera is aligned with the center opening of the light source;

[0049] S2. Adjust the camera and the machine vision lighting source of the present invention to the height of the detection range by adjusting the mechanical mechanism of the detection system;

[0050] S3, turn on the power supply, the machine vision lighting source of the present invention works;

[0051] S4. Obtain the required inclination angle of the LED module according to the detected height, and then rotate the knob of the light source to obtain the required inclination angle of the LED module. The camera starts to work and collects images.

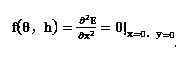

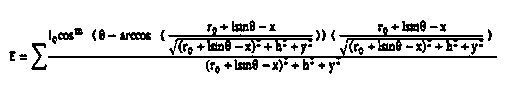

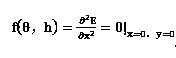

[0052]Wherein, the inclination angle required by the LED module is obtained in the step S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com