Insertion rod

A technology of connecting part and threaded connection, which is used in the connection of rods, connecting components, mechanical equipment, etc., and can solve problems such as inability to insert

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

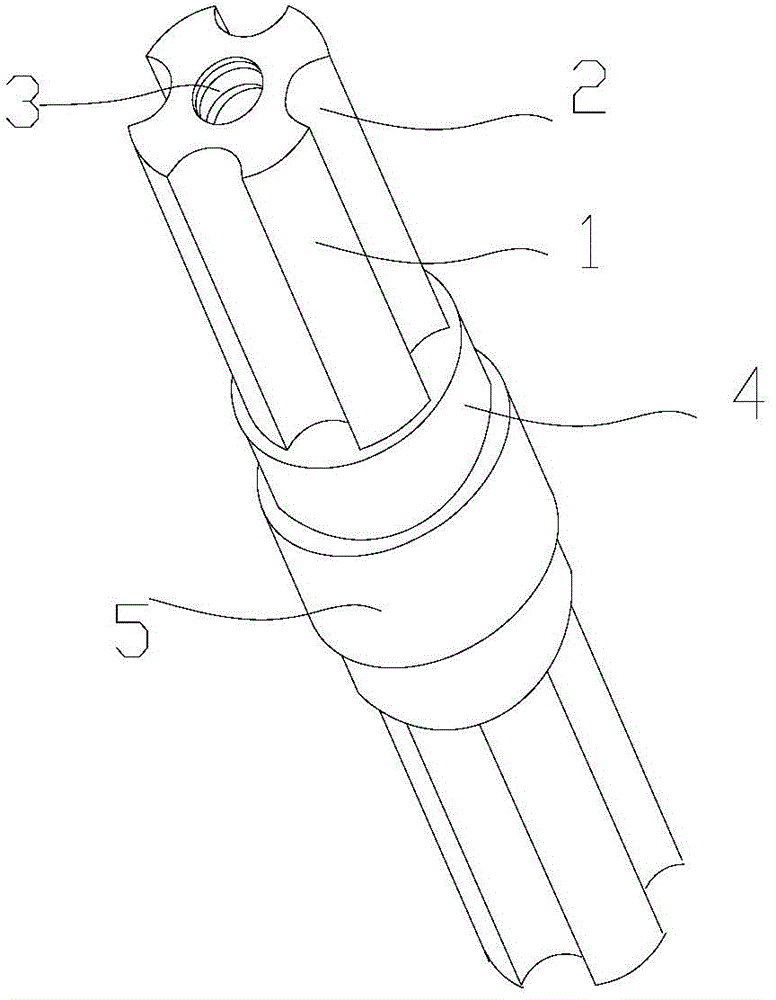

[0010] Inserting rods, including a central rod 1, the outer circumference of the central rod 1 is provided with at least 4 arc-shaped grooves 2, the arc-shaped grooves 2 are parallel to the axial direction of the central rod 1, and the axial direction of the central rod 1 There is a threaded hole 3 in the center, and also includes a sliding sleeve. The sliding sleeve includes a first connecting part 4. The first connecting part is provided with a through hole with the same shape as the central rod. The sliding sleeve also includes a second connecting part. Part 5, the second connecting part is a ring sleeve, and the ring sleeve is connected to the outer periphery of the first connecting part by threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com