Linked piston type plastic sealing material forming system

A water-stop material and piston-type technology, applied in the field of linkage piston-type plastic water-stop material forming system, can solve the problems of heavy equipment, high energy consumption, inconvenient transfer, etc., and achieve high mechanical energy conversion efficiency, simple body structure, The effect of ease of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

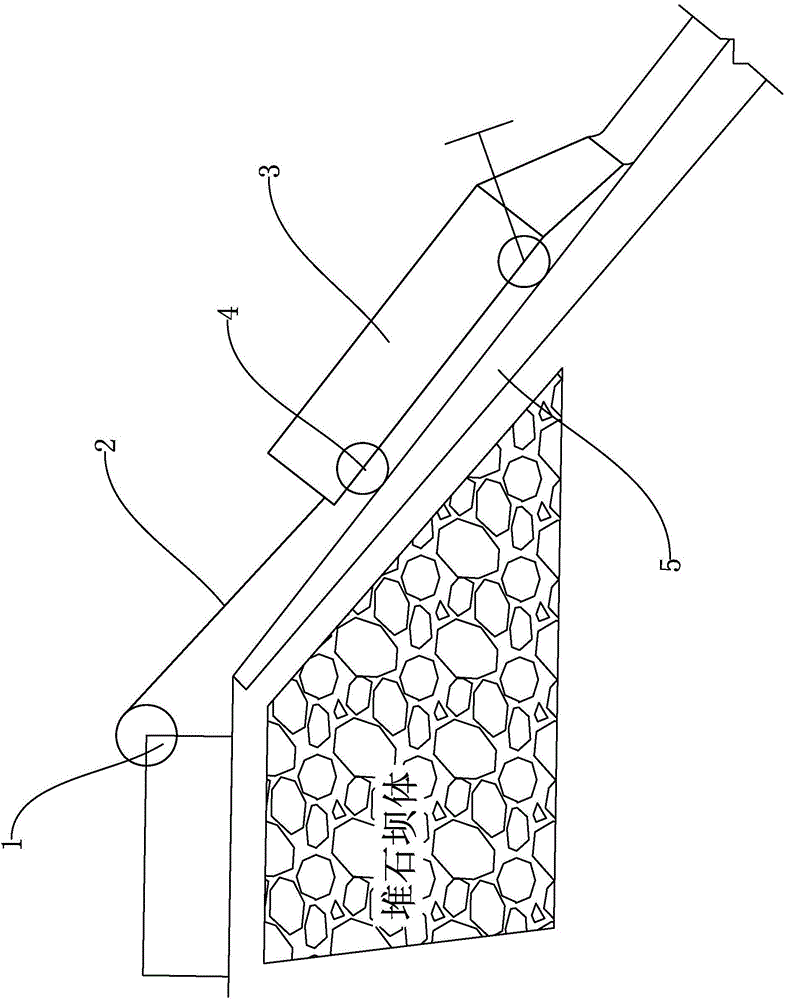

[0019] Such as figure 1 As shown, this embodiment is a linkage piston type plastic water-stop material forming system, which is suitable for face rockfill dams, including a speed-adjustable traction hoist 1, a traction rope 2, and a trolley 4 (a four-wheeled trolley with adjustable direction) , Plastic waterproof material molding device 3 and industrial control module 6.

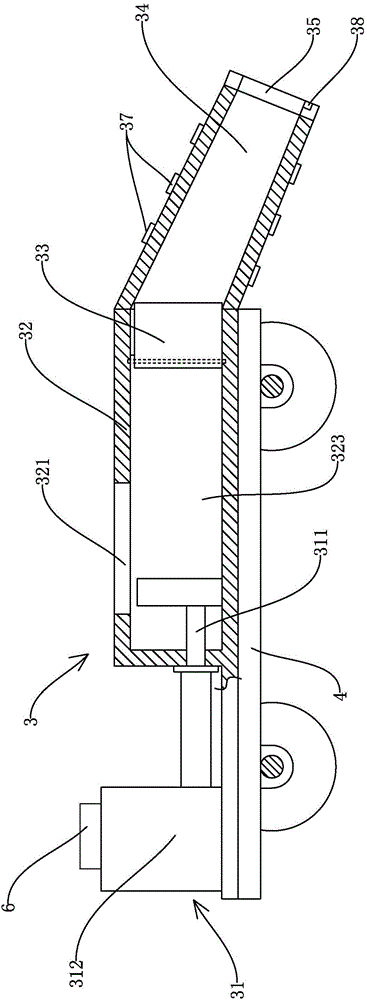

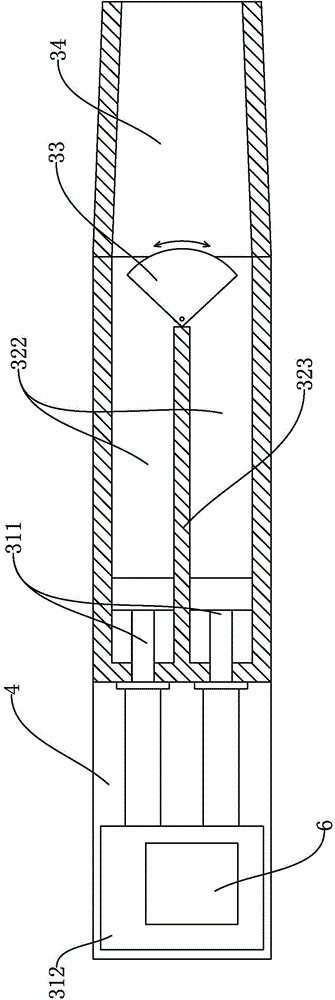

[0020] Such as figure 2 As shown, the plastic water-stop material molding device 3 in this example includes a feeding cavity 32 , and the feeding cavity 32 is divided into two feeding channels 322 on the left and right by a partition 323 . There is a feeding port 321 above the two feeding channels 322, and a double-cylinder hydraulic piston device 31 is arranged at the rear end of the feeding channel 322. The double-cylinder hydraulic piston device includes an electro-hydraulic tank 312 and two hydraulic ejector rods connected with the hydraulic tank. 311, the electro-hydraulic box 312 is located behind t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com