Preparation method of flame retardant sike dimethyl haloethoxysilicate compound

A technology of dimethyl haloethoxysilicate and compound, which is applied in the field of preparation of flame retardant dimethyl haloethoxysilicate compound, can solve the threat of people's life and property safety, fire and other problems, to achieve the effect of high flame retardant element content, high flame retardant efficiency and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

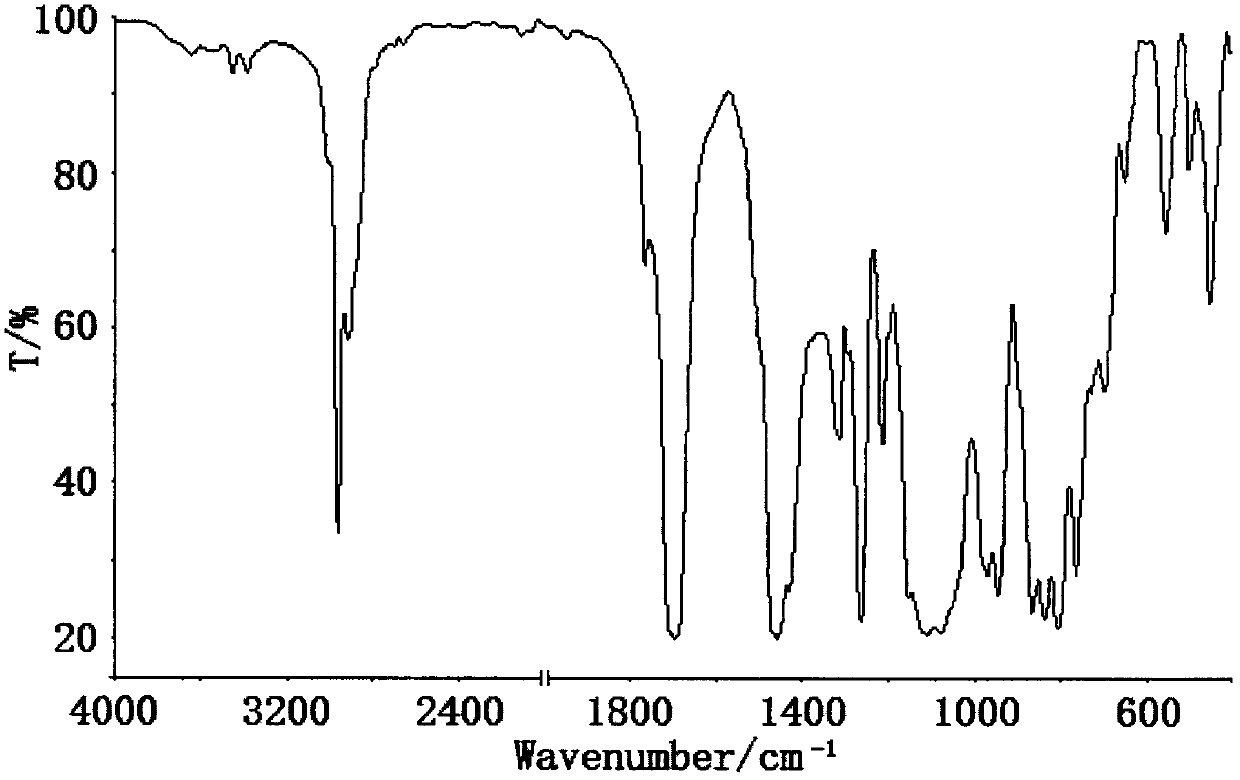

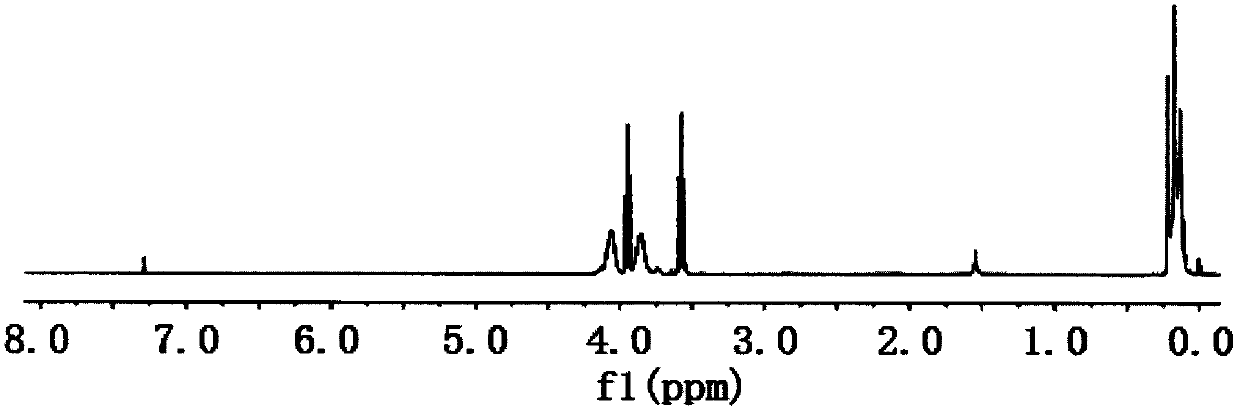

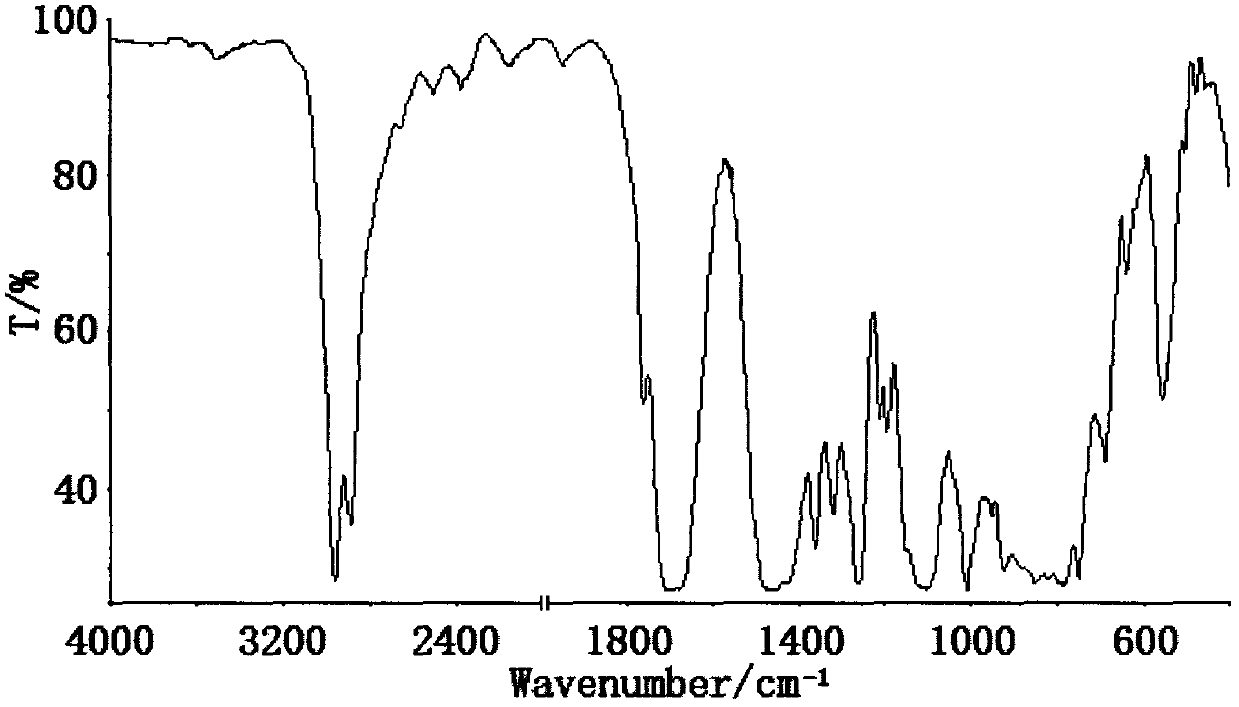

[0036] Embodiment 1 In the 250ml four-necked bottle that stirrer, thermometer and condensation tube are housed, and drying tube and hydrogen halide absorption device are equipped with at the top of condensation tube, replace the air in the bottle with nitrogen, add 8.74g (0.0333 mol) tris(2-hydroxyethyl) isocyanurate and 100ml dioxane, add 12.91g (0.1mol) dimethyldichlorosilane below 30°C, heat up to 70°C, keep warm for 5h; wait for HCl After the gas is released, cool down to below 30°C, add 8.05g (0.1mol) 2-chloroethanol dropwise, and control the reaction temperature not higher than 40°C at the rate of addition, raise the temperature to 100°C after dropping, and keep the temperature for 6 hours; wait for HCl After the gas is released, add 0.25g of melamine, adjust the pH of the system to 5-6, filter with suction, and distill the filtrate under reduced pressure to remove the solvent and a small amount of low boiling point substances to obtain Sac dimethyl chloroethoxysilicate, ...

Embodiment 2

[0037] Example 2 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condensation tube, and a drying tube and a hydrogen halide absorption device on the top of the condensation tube, replace the air in the bottle with nitrogen, and add 8.74g (0.0333 mol) tris(2-hydroxyethyl)isocyanurate and 150ml tetrahydrofuran, add 12.91g (0.1mol) dimethyldichlorosilane below 30°C, raise the temperature to 50°C, and keep the reaction for 9h; wait until the HCl gas is released Finally, cool down to below 30°C, add 8.59g (0.1067mol) 2-chloroethanol dropwise, control the reaction temperature not higher than 40°C at the rate of addition, raise the temperature to 60°C after dropping, keep the temperature for 12 hours; wait until the HCl gas is released Finally, add 0.5g melamine, adjust the pH of the system to 5-6, filter with suction, and distill off the filtrate under reduced pressure to remove the solvent, excess 2-chloroethanol and a small amount of low boiling point, an...

Embodiment 3

[0038] Example 3 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condensation tube, and a drying tube and a hydrogen halide absorption device on the top of the condensation tube, replace the air in the bottle with nitrogen, and add 8.74g (0.0333 mol) tris(2-hydroxyethyl)isocyanurate and 120ml acetonitrile, add 12.91g (0.1mol) dimethyldichlorosilane below 30°C, heat up to 60°C, keep warm for 8h; wait until the HCl gas is released After that, cool down to below 30°C, add 9.39g (0.1167mol) 2-chloroethanol dropwise, control the reaction temperature not higher than 40°C with the dropping speed, raise the temperature to 80°C after dropping, keep the temperature for 8 hours; wait until the HCl gas is released Finally, add 0.8g melamine, adjust the pH of the system to 5-6, filter with suction, and distill off the filtrate under reduced pressure to remove solvent, excess 2-chloroethanol and a small amount of low boiling point, and obtain Sac dimethyl chloroeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com