Curved surface reflector forming equipment and forming method thereof

A technology of curved mirror and molding equipment, which is applied in glass molding, glass remolding, glass manufacturing equipment and other directions, can solve the problems of high cost and high energy consumption, and achieve the effects of low cost, low energy consumption and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

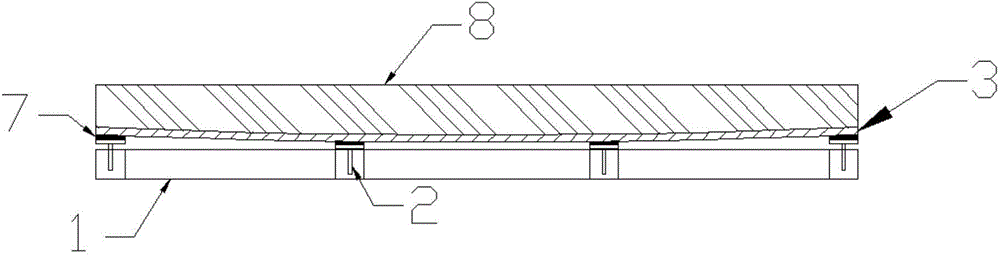

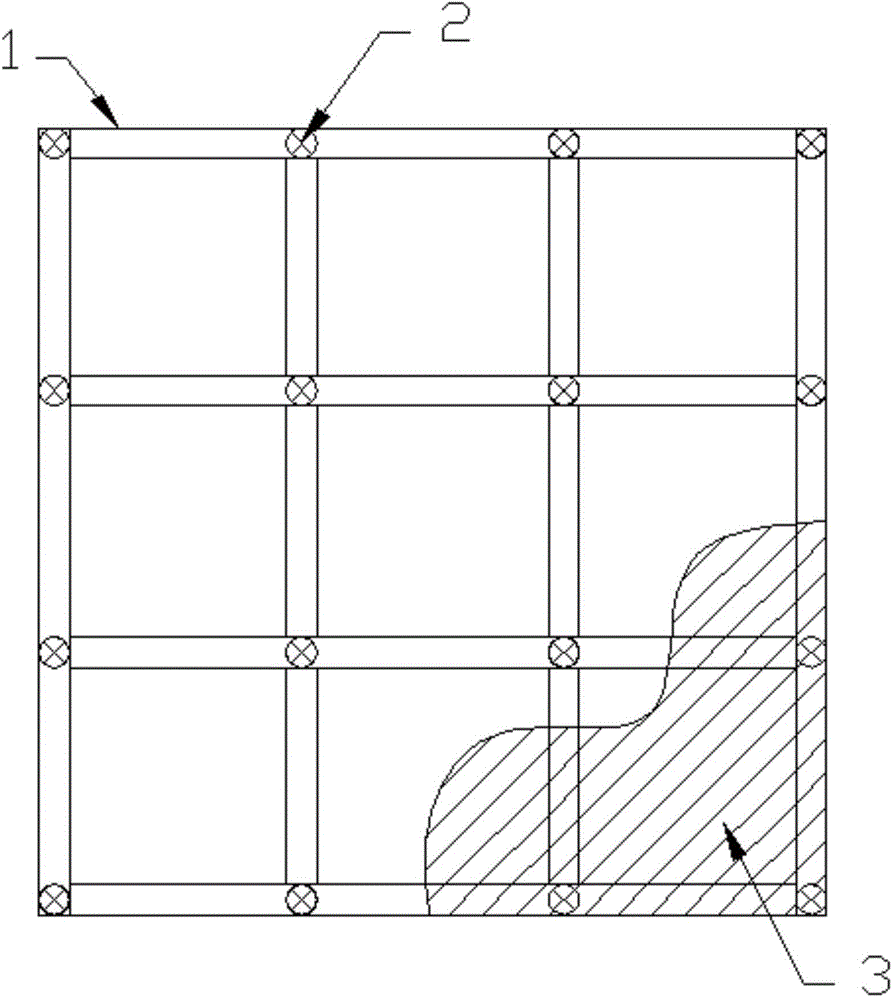

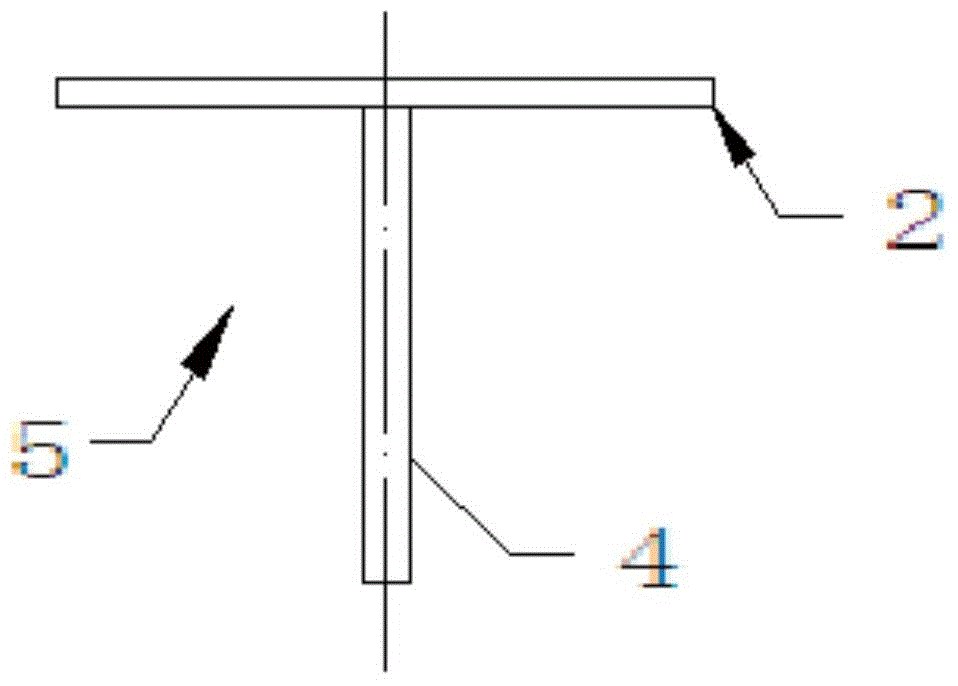

[0032] Such as Figure 1 to Figure 4 A curved surface mirror forming equipment shown includes a molding die, a frame and a plurality of fixing parts. the fixing hole, the height of the lower bar on the fixing part can be adjusted in the fixing hole; the molding die is set opposite to the frame, and the top sheet on the fixing part The forming mold, one surface of the forming mold is a curved surface to be formed, and the processing mirror surface is located between the curved surface to be formed of the forming mold and the top thin plate on the fixing member.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com