Lyophilizer and feed and discharge system linkage fault processing method

A fault handling method and a technology for feeding and discharging materials, which are applied in the directions of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as increasing production costs, and achieve the effects of avoiding waste, being easy to implement, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

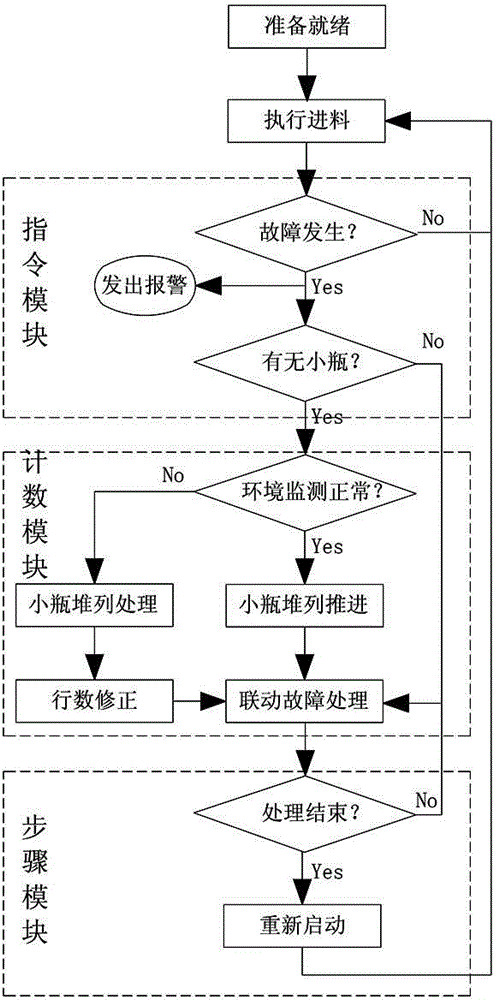

[0023] Such as figure 1 and figure 2 As shown, the linkage fault handling method of the freeze dryer and the feeding and discharging system of this embodiment includes the following steps:

[0024] S1: During the feeding process between the freeze dryer and the feeding and discharging system, when the linkage failure between the freeze dryer and the feeding and discharging system occurs, stop the operation of the feeding and discharging system;

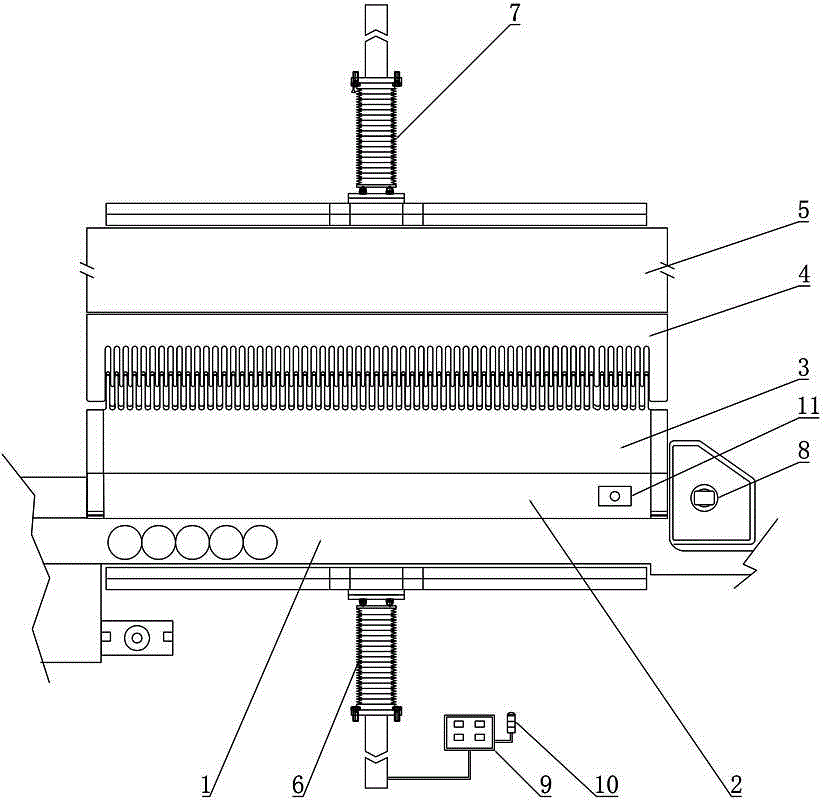

[0025] S2: Detect whether there is a bottle on the transition plate 2 between the feeding and discharging system and the freeze dryer; if there is a bottle, go to step S3, otherwise go to step S4;

[0026] S3: Detect whether the environment of the bottle on the transition plate 2 is polluted, if not, push the bottle on the transition plate 2 into the washboard of the freeze dryer, otherwise clean up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com