Split overflow preventing water tank

A split-type, anti-spill technology, applied in rigid containers, bottle/can parts, containers, etc., can solve the problems of high water level overflow, unfavorable market competition, low production efficiency, etc. Low, enhance the competitiveness of enterprises, the effect of improving mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

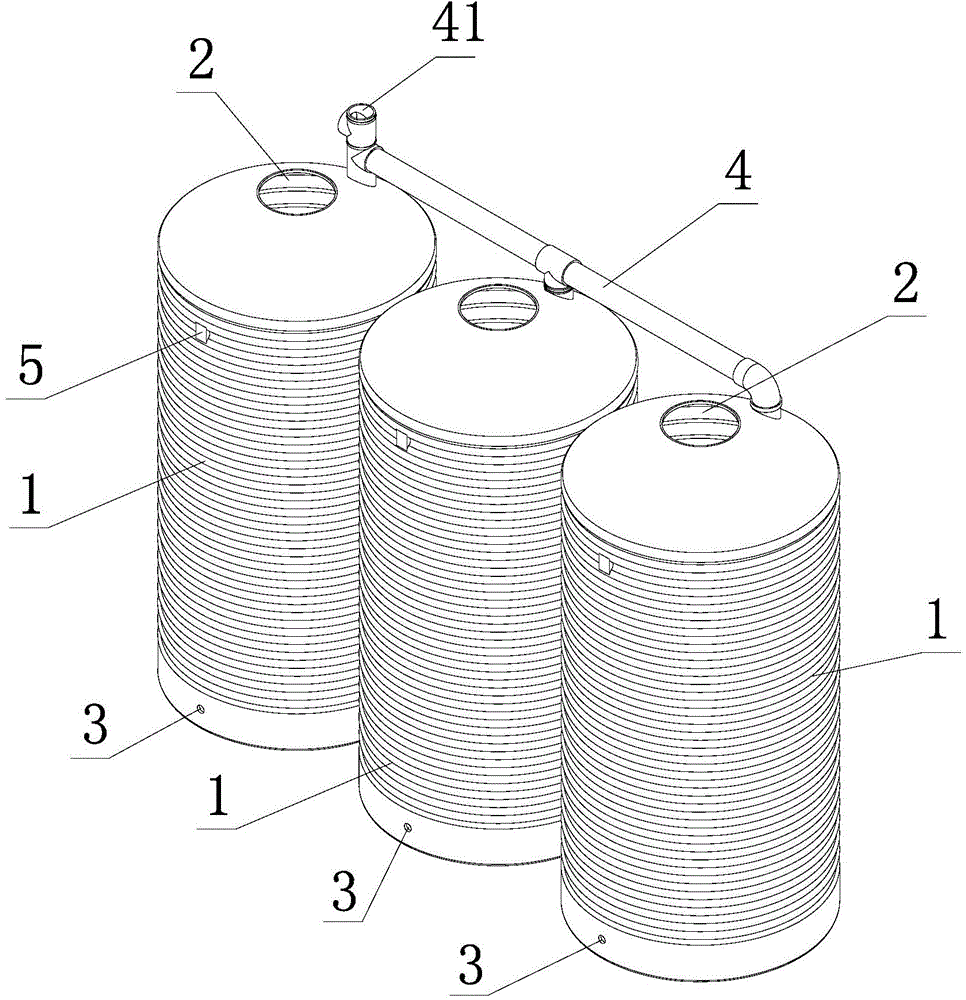

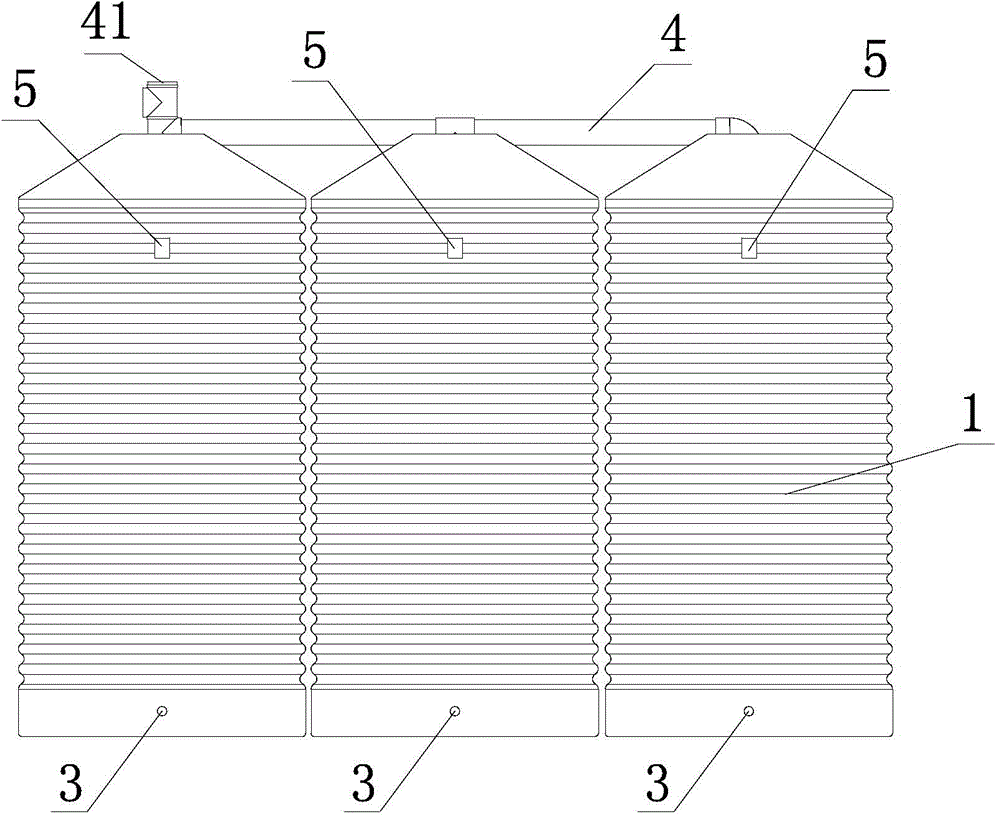

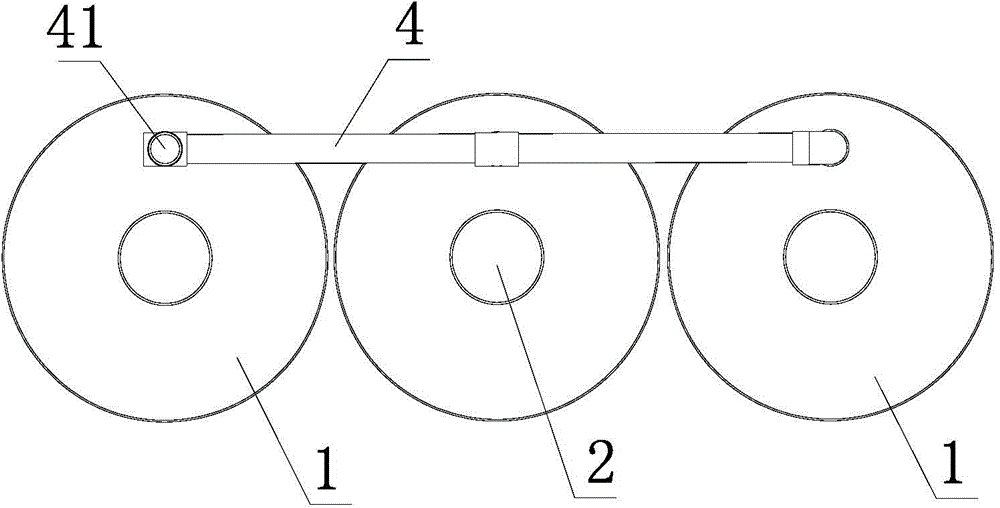

[0015] see figure 1 , figure 2 with image 3 , the present embodiment provides a split type anti-overflow tank, which includes three vertical water storage containers 1 arranged in a "one" shape. The quantity of the water storage containers 1 is set, and the water storage containers 1 can be arranged in triangles or other shapes to meet the needs of various venues. The top of the water storage container 1 is provided with a water inlet 2, and the bottom is provided with a water outlet 3, and one side of the water inlet 2 is provided with a through pipe 4 that can connect the water storage container 1 with the adjacent water storage container 1, And the through pipe 4 is provided with a water inlet 41, which can inject liquid from the water inlet 2 and the water inlet 41 at the same time, saving working time. If it is necessary to produce different products or mix other liquids, other liquids can be injected directly from the water inlet 2. The operation is convenient and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com