Unloading device of knife, fork and spoon packaging machine

A packaging machine and blanking technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of simultaneous falling of multiple materials and packaging effects, and achieve the effect of high blanking stability and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further description will be given below for the embodiments of the present invention:

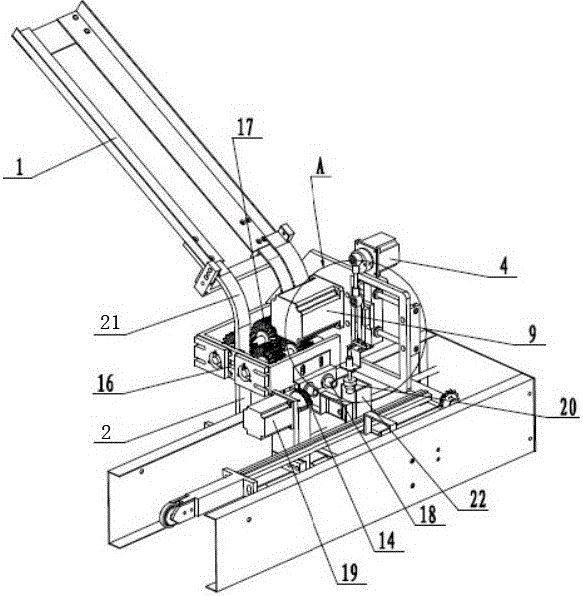

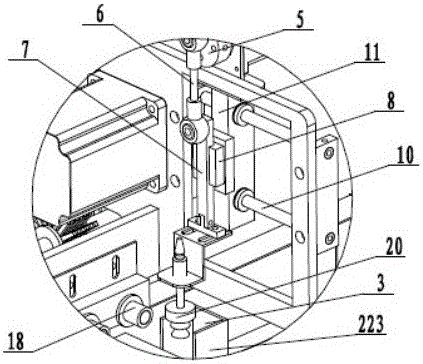

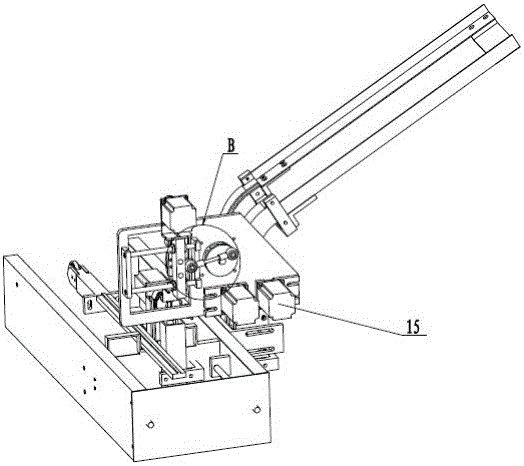

[0021] As shown in the figure, a blanking device of a knife, fork, and spoon packaging machine includes a discharge guide rail 1, a discharge guide rail 2, a feeding mechanism, and a conveying mechanism. The discharge guide rail 1 is used to place materials, discharge materials The guide rail 1 is rectangular, the feeding guide rail 2 is connected with the discharging guide rail 1, and the feeding mechanism is used to push the material to feed along the feeding guide rail 2, and the feeding guide rail 2 includes an arc-shaped transition portion 21 And the material guide portion 22, the material guide portion 22 is U-shaped, including a first vertical portion 221, an arc-shaped bending portion 222 and a second vertical portion 223, and the arc-shaped transition portion 21 is opposite to the discharge guide rail 1 Next, the arc-shaped bending portion 222 is located at the bottom to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com