Automatic feeding device of rod material automatic conveying machine

An automatic feeding and feeding technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of abnormal feeding, bar blockage, economic loss, etc., and achieves good feeding stability, reasonable design, and is not easy to separate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

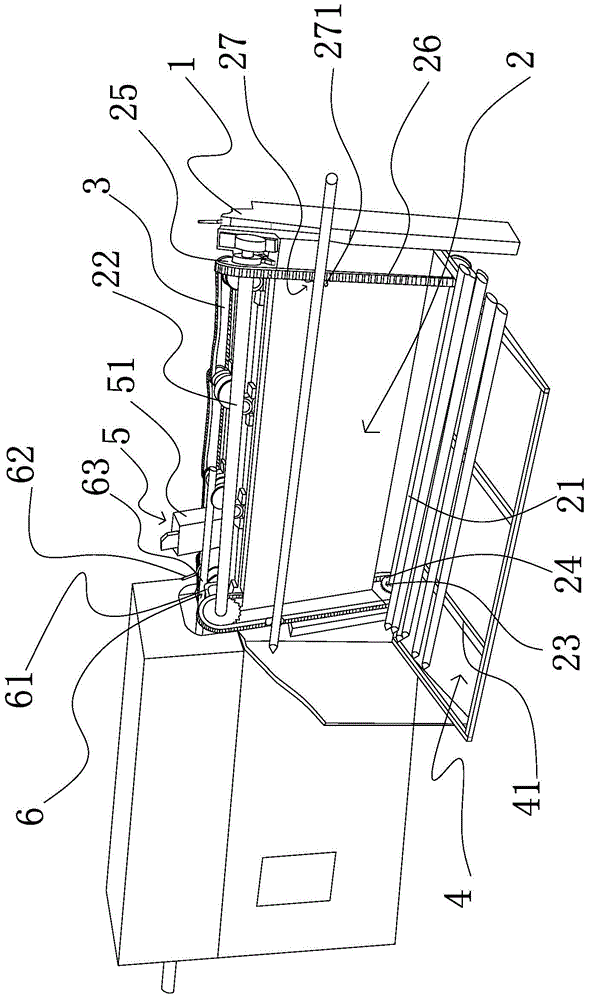

[0017] As shown in Figure 1, the automatic feeding device of this automatic bar feeding machine includes a material storage mechanism 4 arranged on one side of the frame 1 and below the feeding mechanism 3 on the frame 1, the described material storage mechanism 4 and the frame 1 are provided with a lifting mechanism 2 that can horizontally lift the bars placed in the storage mechanism 4 one by one and place the bars on the delivery mechanism 3 one by one. The lifting mechanism 2 is connected to the bar conveying detection mechanism 5 provided at the conveying mechanism 3 and the lifting mechanism 2 can act according to the signal collected by the bar conveying detection mechanism 5 .

[0018] More specifically, the material lifting mechanism 2 includes a driving shaft 21 and a driven shaft 22 that are parallel to each other and are horizontally arranged. A driver 23 is connected to the driving shaft 21 and the bar material delivery detection mechanism 5 is connected to the dri...

Embodiment 2

[0023] As shown in Figure 1, an automatic feeding device for a bar automatic feeding machine, its technical solution is basically the same as that of Embodiment 1, the only difference is that the driving wheel 24 and the driven wheel 25 are not only chains The wheel can also be a pulley or a sheave, and the endless transmission member 26 can be a belt or a rope.

Embodiment 3

[0025] As shown in Figure 1, an automatic feeding device for a bar automatic feeding machine, its technical scheme is basically the same as that of Embodiment 1, the only difference is that there are at least 6 lifting parts 27 arranged on each annular transmission part 26. Pairs and each pair is arranged in a one-to-one correspondence in the horizontal direction to increase the delivery capacity of the bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com