Coal mine well vehicle rotation operation and control unit

A technology for vehicles and coal mines, applied in vehicle components, fluid steering mechanisms, circuits or fluid pipelines, etc., can solve problems such as difficult driving, safety accidents, and difficulties for drivers to turn and turn their heads, so as to improve driving comfort and reduce fatigue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

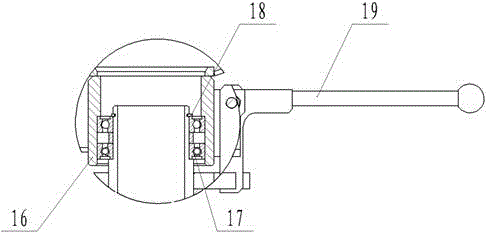

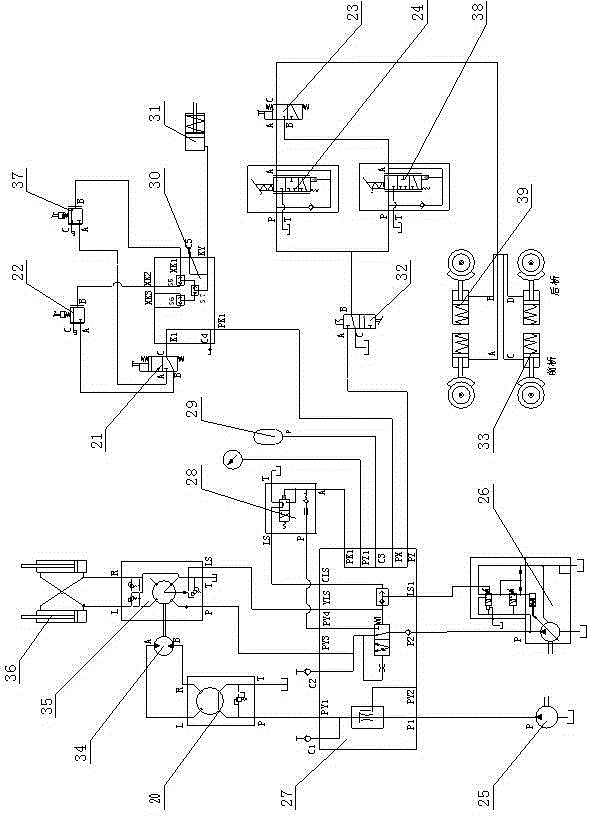

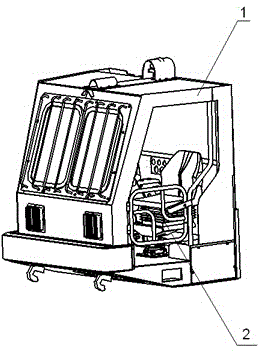

[0026] A rotary control unit for a coal mine underground vehicle. The rotary control unit 2 is arranged in a mechanical engineering cab 1. The rotary control unit 2 includes an installation platform 4, a follow-up control unit 3 arranged on the installation platform 4, a hydraulic control system 7 and a speed Brake control switching device 8, the installation platform 4 is respectively provided with a speed controller 5 and two brake controllers 6 along the two directions of vehicle travel; the follow-up control unit 3 includes a rotary hand wheel 9, a transmission control device 14, seat 10, transmission control actuator 13, rotating support 11 and rotating positioning device 12, the seat 10 is arranged on the rotating support 11, and the lower end of the rotating support 11 is provided with a rotating positioning device 12, the front of the seat 10 There is a rotary handwheel and a transmission controller 14 for controlling the steering of the vehicle, and a transmission actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com