PC wall panel production system

A production system and wall panel technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of unsealed curing rooms, low mold utilization, and low efficiency, so as to avoid workshop area and save production occupation The effect of increasing the floor area and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

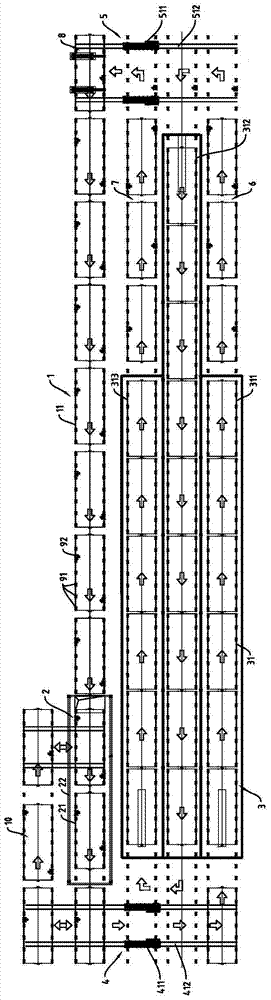

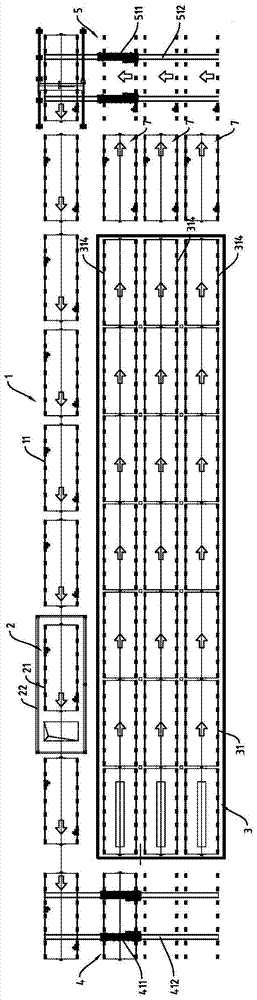

[0035] Figure 1 to Figure 2 It shows a PC wall panel production system in the present invention. This PC wall panel production system is different from the traditional production method, which can make the PC wall panel mold circulate, and each operator only needs to complete it at a specific position. A certain step in the whole operation steps is sufficient, which not only reduces the number of operators, but also refines the types of work of the operators, improves the operation efficiency, and is beneficial to the finished product effect and production efficiency of the PC wallboard.

[0036] figure 1 It is a structural schematic diagram of a PC wallboard production system in an embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com