Wood processing machine tool

A technology for processing machine tools and machine tools, which is applied in the direction of wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve problems such as increased labor costs, high work intensity, and high safety hazards, so as to save labor costs, avoid safety hazards, avoid The effect of maintaining the movement of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

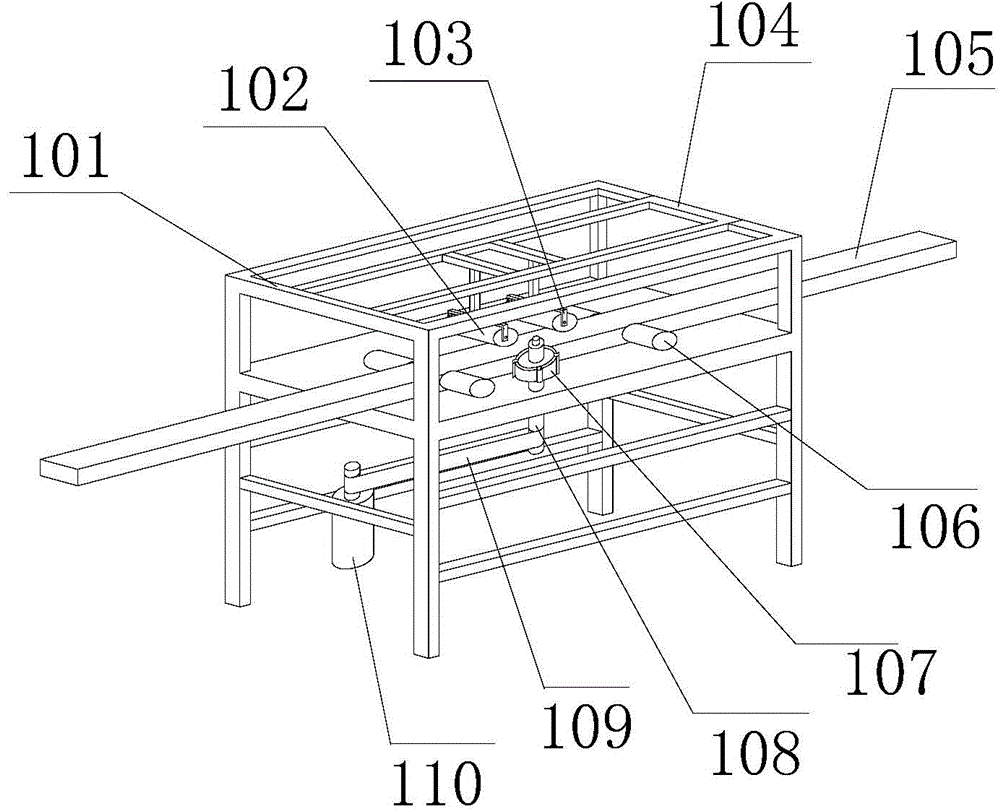

[0054] Such as Figure 1-4 As shown, in this embodiment, a wood processing machine tool is provided, which includes: a machine tool frame 101, a pressure wheel frame 104, a first motor, two pairs of rollers 106, a bolt, and an end mill.

[0055] The machine frame 101 is provided with a work table; the two pairs of rollers 106 are arranged on the table surface of the work table along the feeding direction.

[0056] The pressure wheel frame 104 is provided with a pressure wheel frame rotation shaft 119, the pressure wheel frame 104 is rotatably connected to the machine tool frame 101 through the pressure wheel frame rotation shaft 119, and the pressure wheel frame 104 is connected with a roller frame 103; The processing machine tool also includes a roller 102 for stabilizing wood. The two ends of the roller 102 are connected to the roller frame 103 and the roller 102 can roll along the axis of the roller 102. The axes of the rollers 106 are parallel; the first motor is arranged on th...

Embodiment 2

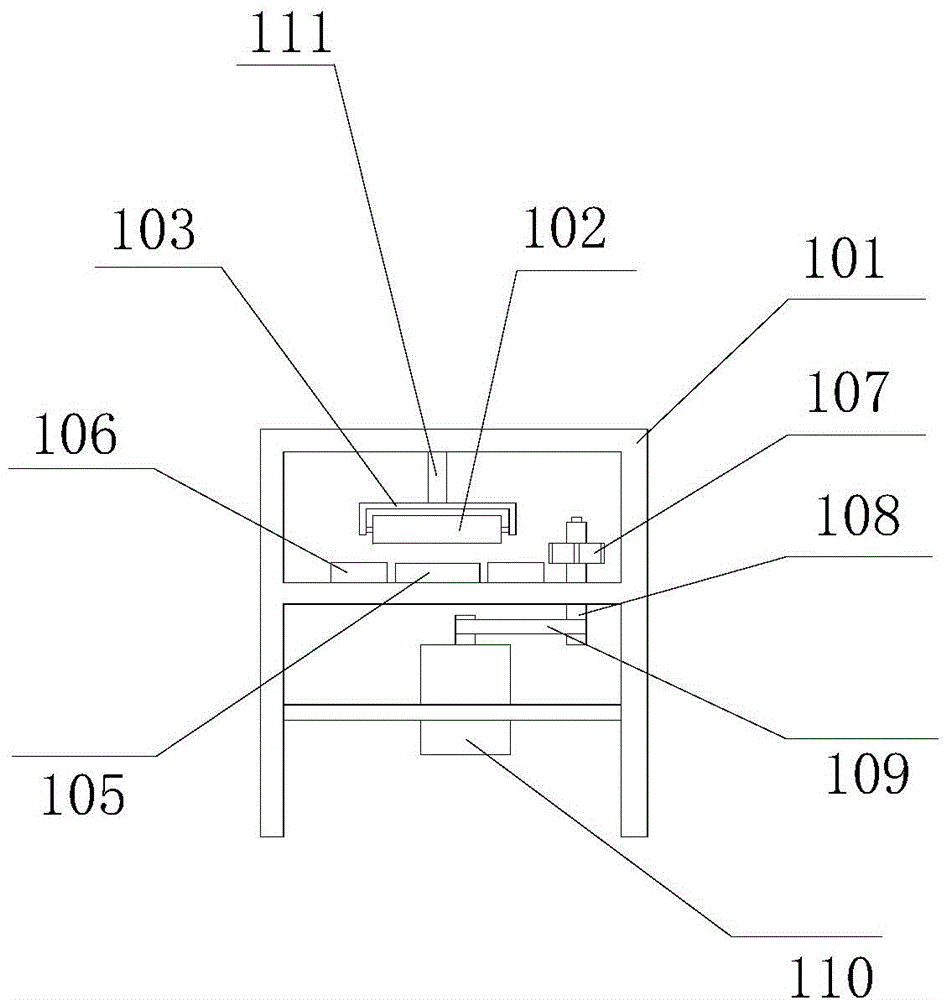

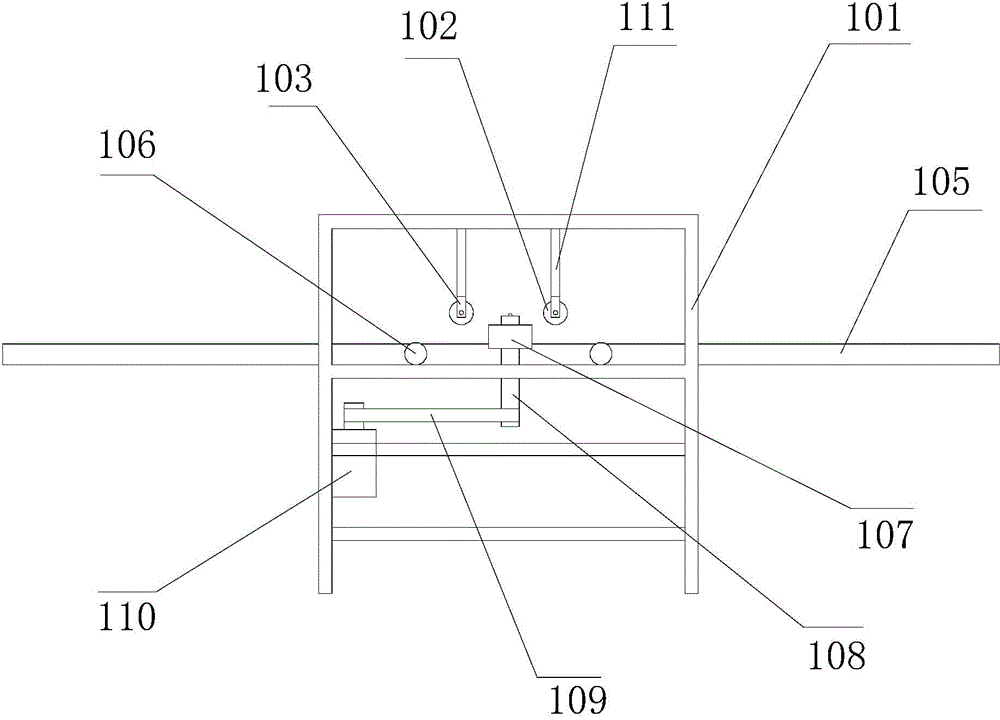

[0071] Such as Figure 5-10 As shown, this embodiment provides a wood processing machine tool, including: a machine tool frame 101, a pressure wheel frame 104, a first motor, a feed track 105, two pairs of rollers 106, a bolt, and a tenoning device.

[0072] The machine frame 101 is provided with a work table; two pairs of rollers 106 are sequentially arranged on the table surface of the work table along the feeding direction; the feed track 105 is set on the table surface of the work table and is located between the two pairs of rollers 106 between.

[0073] The pressure wheel frame 104 is rotatably connected to the machine tool frame 101 through the pressure wheel frame shaft 119, the pressure wheel frame 104 is connected with a shock absorber 111, and the shock absorber is connected with a roller frame 103; the processing machine tool It also includes a roller 102 for stabilizing wood. Both ends of the roller 102 are connected to the roller frame 103 and the roller 102 can rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com