Track maize harvesting machine

A corn harvester and crawler-type technology, applied in the field of harvesters, can solve problems such as long response time, inability to work, inability to reverse rotation of rotating parts, or adjustment of speed, so as to achieve reasonable matching between operation and driving, and convenient installation, use and maintenance , The effect of reducing auxiliary work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

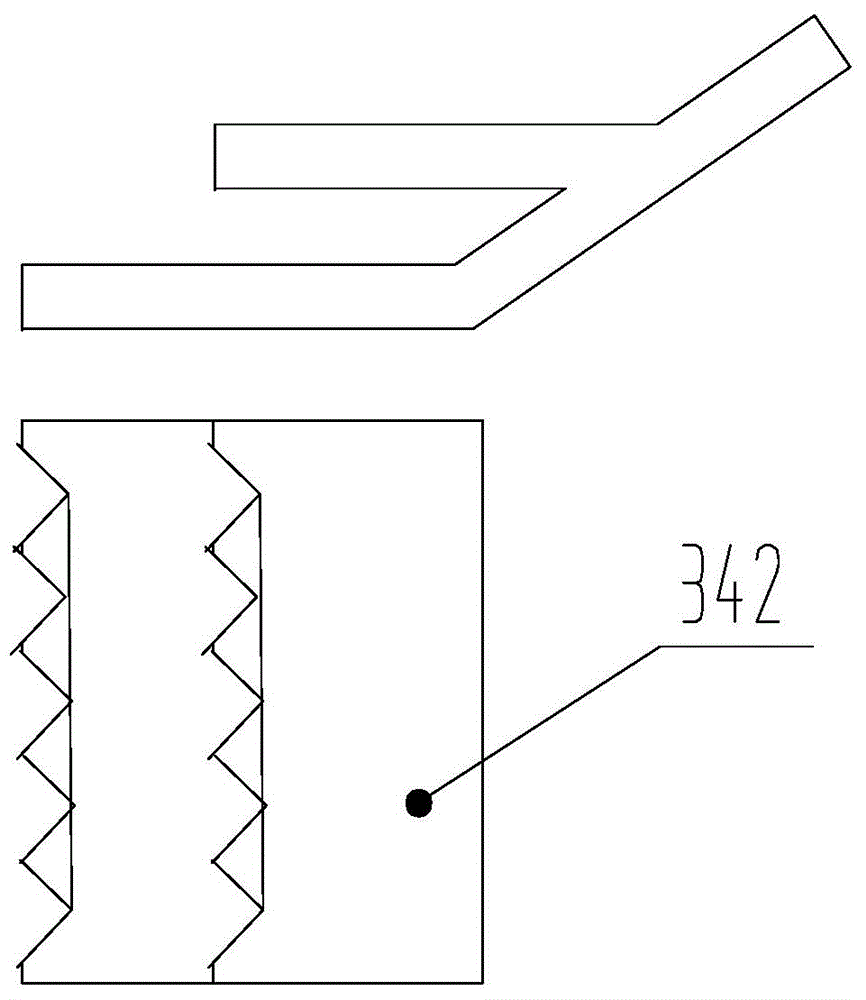

[0018] A crawler corn harvester mainly includes an engine 1, a working device 2, a chassis assembly 3, a cab 4 and a hydraulic system 5; the working device 2 includes a header system 21, an ear bin 23 and the The ear conveyor 22; the header system 21 includes the ear cutting device 211; the chassis assembly 3 includes the transmission device 31, the steering brake device 32 and the crawler driving system 33; the crawler driving system 33 includes the vehicle frame 34 and walking gear 35; the front portion of the frame 34 is provided with a header bracket 341 for installing the header system 21; the lower end of the header bracket 341 is provided with a straightening mechanism 342; the working device 2 and the cab 4 are left One right one is fixed on the connecting plate 343 at the front portion of the vehicle frame 34, and the ear bin 23 is arranged at the rear of the vehicle frame 34; the hydraulic system 5 includes a hydraulic valve 51, a hydraulic oil tank 52, a steering cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com