Sheaf binder

A baler and frame technology, applied in the field of harvesting machinery, can solve the problems of difficult cutting, crop impact, waste, etc., and achieve the effect of increasing the supporting area, reducing the impact force and improving the supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

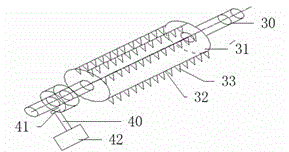

[0012] Such as figure 1 As shown, a kind of baler includes a frame 1 and a traveling mechanism arranged on the frame, a power mechanism, a header 2 and a grain reel 3, and the traveling mechanism includes a driving wheel and a corresponding shaft to drive the baler to advance The structure, the power mechanism provides the operating power mechanisms such as the traveling wheel, the reel 3, and the header, and the header 2 cuts the stalks of the crops. Grass reel 3 is contained in this harvesting platform 2 tops, and is spaced a certain distance with it, in order to avoid cutting knife to contact this grains reel, damage machine. The reel 3 includes a wheel shaft 30 at the center, and its two sides are fixedly sleeved on a spoke disc 31 , and the spoke disc 3 is provided with spokes 32 parallel to the wheel shaft 30 . This spoke is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com