Conveyor device for printed circuit boards

A technology for printed circuit boards and transportation equipment, which is applied in the directions of printed circuits, welding equipment, transportation and packaging, and can solve problems such as difficulty in the process of placing circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

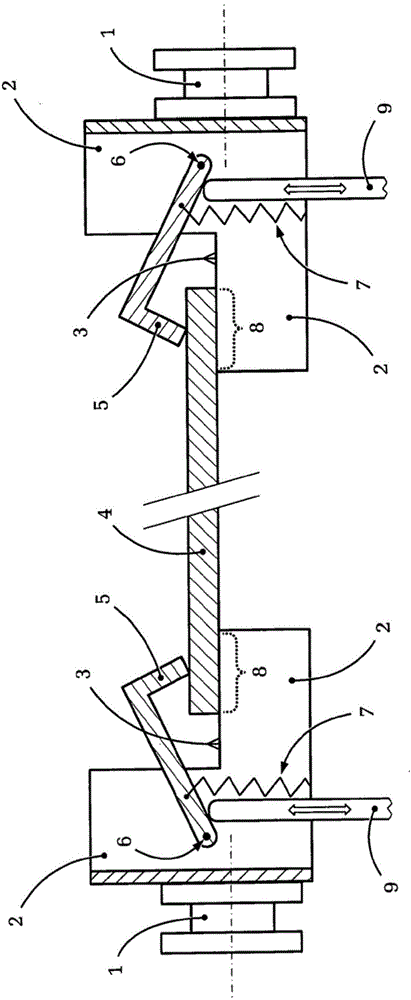

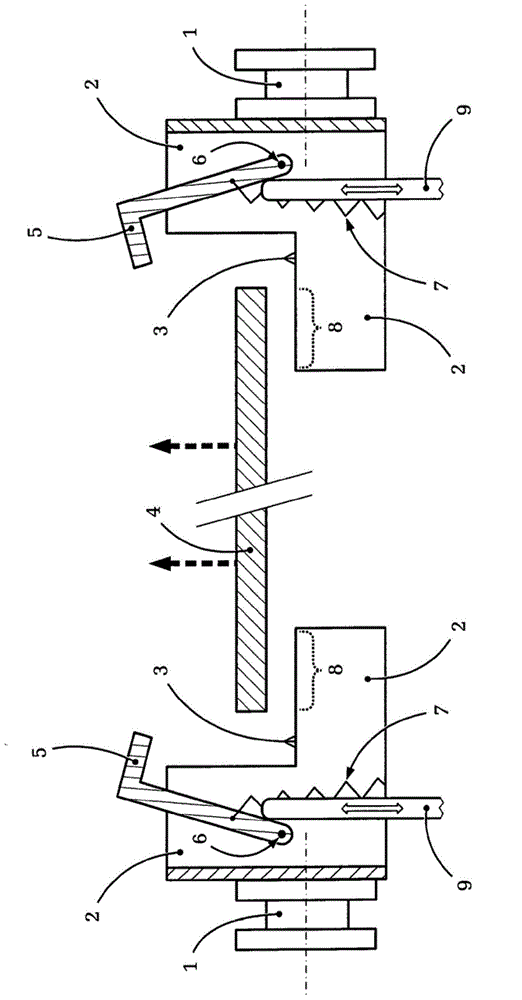

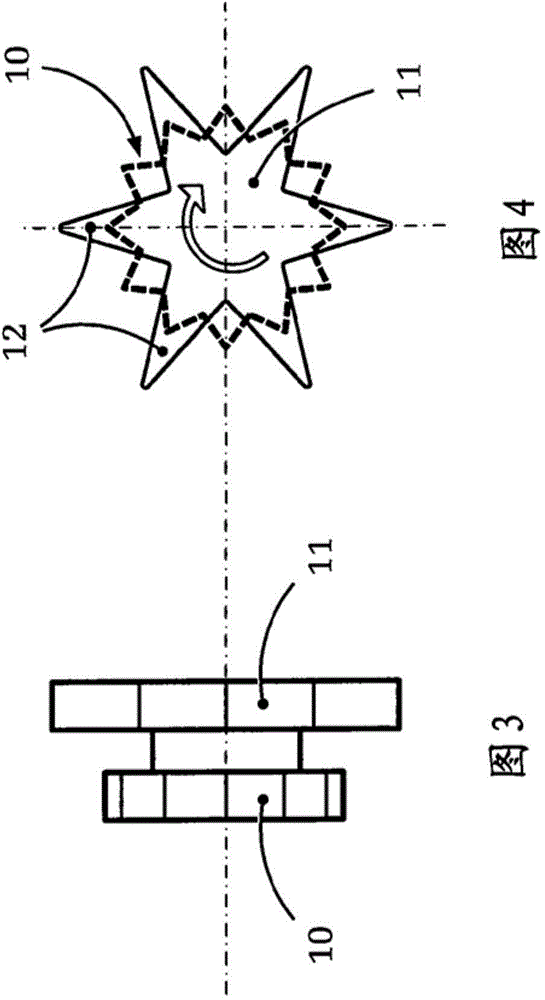

[0032] figure 1 and figure 2 In the highly schematic illustration, a partial section through a transport device according to an embodiment of the invention is shown in each case.

[0033] exist figure 1 and figure 2 In each case two endless chains 1 are seen running along the transport system (here perpendicular to the plane of view). On the ring chain 1 are respectively provided with a plurality of bearing elements 2 (in figure 1 or figure 2 Only one of the carrying elements 2 is visible or shown for each endless chain 1). The carrier element 2 has a mounting area 3 on which the figure 1 A schematically represented circuit board 4 is arranged in the.

[0034]The transport device also includes clamping elements 5 , each associated with a carrier element 2 , which are respectively pivotable about an articulation axis 6 relative to the carrier element 2 . The clamping elements 5 are each pressed by means of the coil springs 7 in the direction of the mounting area 3 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com