Improved sub-harmonic mixer based on coplanar waveguide transmission line

A coplanar waveguide and transmission line technology, applied in the terahertz field, can solve problems such as increasing assembly difficulty and reducing circuit accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

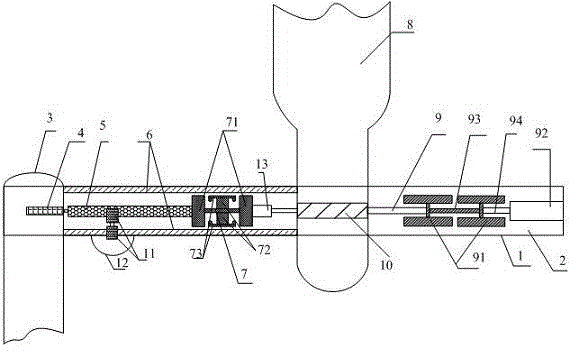

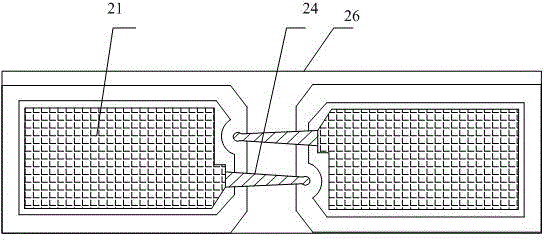

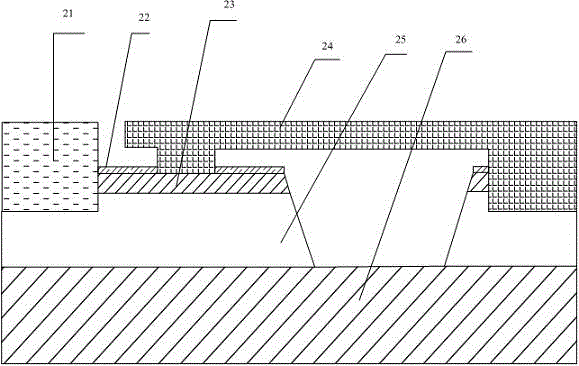

[0038] Such as Figure 1 to Figure 9 shown.

[0039] An improved subharmonic mixer based on a coplanar waveguide transmission line, comprising a main air cavity 1, the inner bottom surface of the main air cavity 1 is provided with a dielectric substrate 2, and the dielectric substrate 2 is provided with a coupling probe 4, coplanar Waveguide transmission line, local oscillator matching line 10, microstrip line structure, coplanar waveguide transmission line includes matching line 5, first transverse transmission line 7, local oscillator low-pass filter matching line 13, and coupling probe 4 connected in sequence from left to right The right end is connected to the left end of the matching line 5, the right end of the local oscillator low-pass filter matching line 13 is connected to the left end of the local oscillator matching line 10, and the microstrip line structure includes the second transverse transmission line 9 and the third transverse transmission line connected seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com