Rotor Of Rotary Motor

A technology for rotating electrical machines and rotors, applied in the field of rotors of rotating electrical machines, can solve the problems of inability to set up ventilation ducts, loss of mechanical strength, noise, and lack of ventilation ducts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

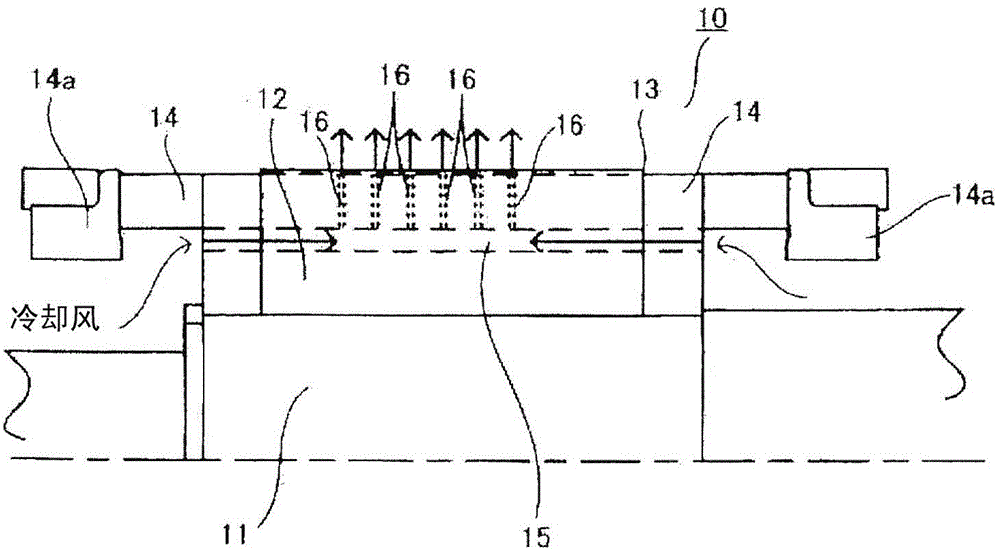

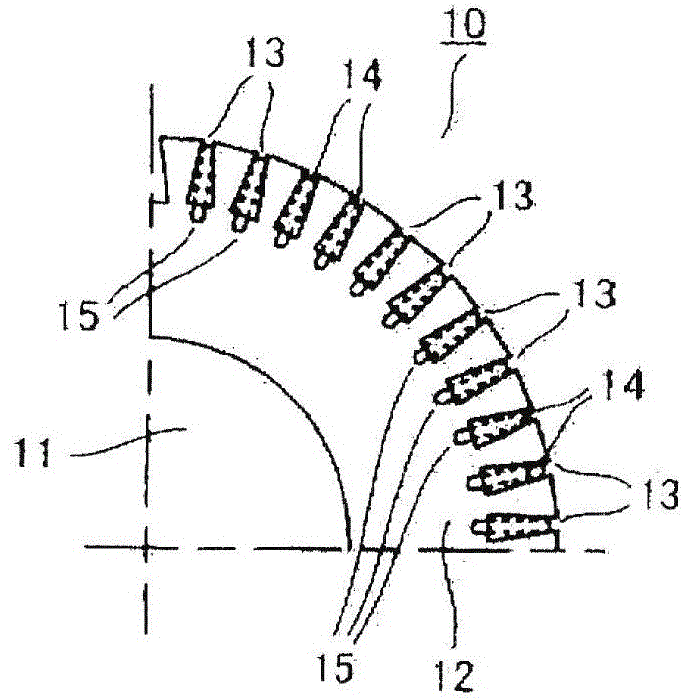

[0009] figure 1 shows the rotor 10 of the rotating electrical machine of this embodiment, figure 2 1 / 4 of the cross section of the rotor 10 is shown.

[0010] exist figure 1 and figure 2 Among them, the rotor 10 is constituted by fitting and mounting a rotor core 12 on the outer peripheral surface of a rotating shaft 11 . On the outer peripheral surface of the rotor core 12, figure 1 The illustrated plurality of slots 13 are respectively formed in the axial direction, and the rotor rods 14 are respectively accommodated in these slots 13 . Both ends of these rotor bars 14 are connected to each other by end rings 14a.

[0011] In addition, on the rotor core 12, the ventilation slots 15 slotted at the bottom of the plurality of slots 13 are respectively formed along the length direction of the corresponding slots 13, as figure 1 As shown, their b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com