Shoe making method applying three-dimensional sole data

A technology of three-dimensional data and soles, which is applied in the fields of electrical digital data processing, special data processing applications, footwear, etc., can solve the problems that the shoemaking process does not have personalized shoemaking, cannot solve personalized shoemaking and rapid mass production, etc. , to achieve the effect of solving high-cost contradictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

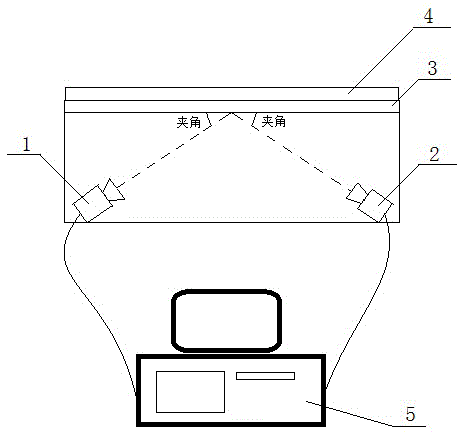

[0019] Example figure 1 As shown, the present embodiment provides a shoe-making method using the three-dimensional data of the sole, including the steps: Step a scans the sole, and obtains the accurate three-dimensional value of the sole through the upper top surface of the fixed area size of the three-dimensional data processing system of the sole. Size; step b matches the existing shoe last to obtain the instep size according to the obtained three-dimensional size of the sole; step c automatically processes the three-dimensional shape of the sole according to the three-dimensional size of the sole; step d adopts the traditional stretched upper, glued and three-dimensional shaped sole Bonding shoemaking; step e, pulling off the last to obtain a three-dimensional shoe that matches the three-dimensional size data of the sole of the human f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com