Dedicated mold for testing electrical property of lithium iron phosphate

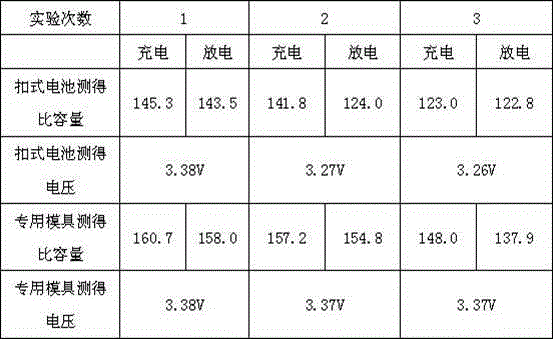

A lithium battery and iron phosphate technology, applied in the field of new energy material testing, can solve problems such as unsatisfactory result consistency, large errors, and difficulties, and achieve the effects of saving test costs, reducing test result errors, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

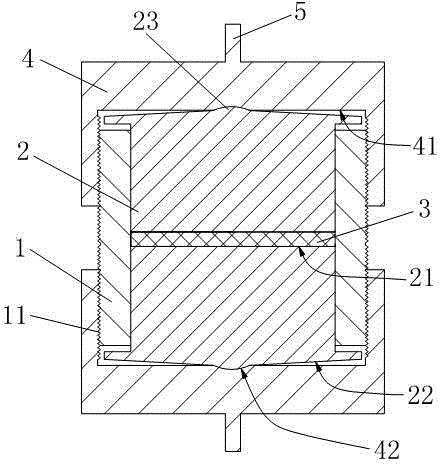

[0018] The present invention will be described in further detail below according to the drawings and embodiments.

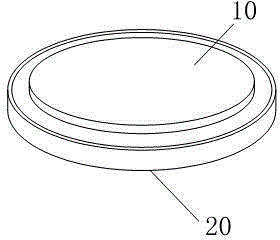

[0019] Such as figure 2 As shown, a special mold for lithium iron phosphate electrical testing described in the embodiment of the present invention includes: an insulating sleeve 1, the insulating sleeve 1 has a through hole, and the outer two ends of the insulating sleeve 1 are respectively provided with external threads 11; The conductive pressure block 2 at both ends of the insulating sleeve 1 is used to fill the lithium iron phosphate powder 3 between the two conductive pressure blocks 2; the conductive shell 4 installed at both ends of the insulating sleeve 1, the conductive shell 4 has an external thread 11 With matching internal threads, the inner wall 41 of the conductive housing 4 abuts against and compresses the conductive compression block 2 .

[0020] In order to better contact the lithium iron phosphate, the opposite end surfaces 21 of the two cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com