Optical fiber electric field sensor

A fiber optic electric field and sensor technology, applied in the direction of electrostatic field measurement, etc., can solve the problems of low sensor stability and reliability, easy displacement, no coupling, etc., and achieve the effect of solving structural stability problems

Inactive Publication Date: 2015-05-27

DALIAN KANGSAIPU TECH DEV

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This structure has obvious disadvantages: 1. Due to no positioning measures, the optical components are not fixed, and displacement is easy to occur; 2. Since the connection between the lens and the end face of the polarizer is suspended, the structure is unstable, and displacement is easily generated, even Falling off leads to a change in the coupling efficiency between the input lens and the output lens, or even no coupling; 3. Because the structure is not fixed, the bonding is random, and the bonding is often uneven, and the front and rear are misaligned. It is also difficult to make an ideal sensor with a five-dimensional fine-tuning instrument, and it is time-consuming

In short, the stability and reliability of the sensor with the above structure are not high, the processing technology is difficult, the production efficiency is low, and the dispersion is large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

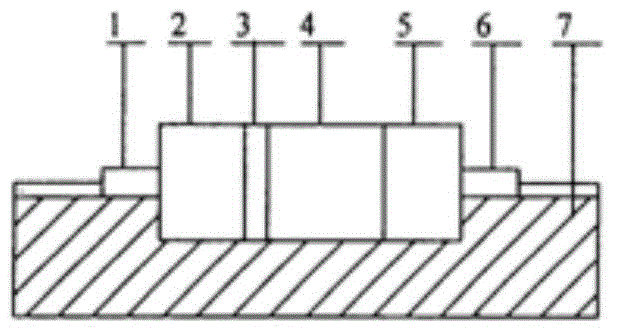

[0009] Such as figure 1 and figure 2 As shown, the collimator lens 1, polarizer 2, λ / 4 wave plate 3, electro-optic crystal 4, analyzer 5, and coupling lens 6 are sequentially placed in the groove of the plexiglass substrate 7, and bonded with optical glue, Close the upper part of the plexiglass substrate, and stick the upper and lower parts firmly to make an optical fiber electric field sensor.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an optical fiber electric field sensor, which belongs to a photoelectric measuring device and measures an electric field based on the photoelectric effect. The optical fiber electric field sensor comprises a collimating lens, a polarizer, a Lambda / 4 wave plate, an electro-optic crystal, an analyzer, and a coupling lens, which are sequentially placed on an optical path. The optical elements are embedded onto an organic glass substrate, the organic glass substrate is provided with grooves matched with the embedded optical elements in shape and order, the optical elements are adhered together by optical adhesive, and the optical elements and the organic glass substrate are adhered together by optical adhesive. The optical elements are not easy to shift. The collimating lens and the coupling lens are on the same line in the same plane. The structure is stable. The lenses can be aligned with each other easily. The coupling efficiency is high. Connection and debugging of an optical path system are convenient. The reliability and stability of the sensor are greatly improved. The process is greatly simplified.

Description

technical field [0001] The invention belongs to a photoelectric measuring device, which measures the electric field based on the photoelectric effect. Background technique [0002] There have been many reports in the literature on the measurement of electric field based on the Pockels electro-optic effect principle. The main principle of the sensor is a collimator lens, a polarizer, a λ / 4 wave plate, an electro-optic crystal, an analyzer and a coupling lens. The process is that the light emitted by the LED is transmitted to the electric field sensor through the optical fiber, coupled into the polarizer by the collimator lens, and then the phase shift of π / 2 is generated by the λ / 4 wave plate, and then enters the electro-optic crystal. Under the action of the electric field, The light undergoes birefringence, that is, the photoelectric effect. The phase difference between the two birefringent beams is proportional to the applied electric field strength, and then the light is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01R29/12

Inventor 鞠洪建

Owner DALIAN KANGSAIPU TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com