A method for collecting and storing waste water from fire accidents in chemical workshops

A storage method and waste liquid collection technology, which are applied in waterway systems, sewage removal, water supply devices, etc., can solve the problems of collection and storage methods that have not seen relevant reports, and achieve the effects of saving reconstruction costs, facilitating processing, and low construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

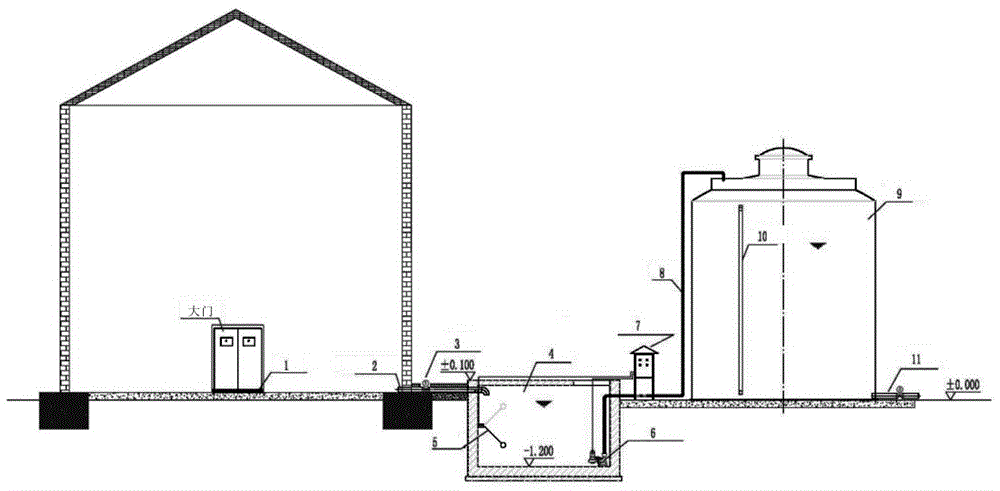

Image

Examples

Embodiment 1

[0030] Example 1: The chemical workshop covers an area of S=1500m 2 , the daily transfer of chemicals in the workshop weighs about W=20 tons and is converted into N=20m 3 , the volume of the storage tank is ≥20m 3 According to the GB50016-2006 standard, it is assumed that when a fire occurs, the total water output of the indoor fire nozzle and the outdoor fire nozzle within 3.0 hours of fire fighting time is L=486m 3 , Xiamen local maximum rainfall within 3.0h is calculated as 40mm, then the estimated volume of rainwater E=S×T=60m 3 , the maximum estimated amount of fire accident wastewater=N+L+E=566m 3 .

[0031] According to H=M / S=37.8cm, the chemical workshop can form a 567m 3 Concentrated capacity pool, plus ≥2m 3 sump and 20m 3 The storage tank has a total capacity of 589m for collecting and storing fire accident wastewater 3 , enough to meet the collection and storage of the chemical workshop fire accident wastewater.

Embodiment 2

[0032] Example 2: Chemical workshop covers an area of S=2000m 2 , the daily transfer of chemicals in the workshop weighs about W=30 tons and is converted to N=30m 3 , the volume of the storage tank is ≥30m 3 According to the GB50016-2006 standard, it is assumed that when a fire occurs, the total water output of the indoor fire nozzle and the outdoor fire nozzle within 3.0 hours of fire fighting time is L=540m 3 , Xiamen local maximum rainfall within 3.0h is calculated as 40mm, then the estimated volume of rainwater E=S×T=80m 3 , the maximum estimated amount of fire accident wastewater=N+L+E=650m 3 .

[0033] According to H=M / S=32.5cm, the chemical workshop can form a 650m 3 Concentrated capacity pool, plus ≥2m 3 sump and 30m 3The storage tanks have a total capacity of 682m for collecting and storing fire accident wastewater 3 , enough to meet the collection and storage of the chemical workshop fire accident wastewater.

Embodiment 3

[0034] Example 3: Chemical workshop covers an area of S=3500m 2 , the daily transfer of chemicals in the workshop weighs about W=40 tons and is converted into N=40m 3 , the volume of the storage tank is ≥40m 3 According to the GB50016-2006 standard, it is assumed that when a fire occurs, the total water output of the indoor fire nozzle and the outdoor fire nozzle within 3.0 hours of fire fighting time is L=540m 3 , Xiamen local maximum rainfall within 3.0h is calculated as 40mm, then the estimated volume of rainwater E=S×T=140m 3 , the maximum estimated amount of fire accident wastewater=N+L+E=720m 3 .

[0035] According to H=M / S=20.6cm, the chemical workshop can form a 721m 3 Concentrated capacity pool, plus ≥2m 3 sump and 40m 3 The storage tanks have a total capacity of 763m for collecting and storing fire accident wastewater 3 , enough to meet the collection and storage of the chemical workshop fire accident wastewater.

[0036] The method of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com