Underground pipeline sedimentation repair high polymer membrane bag grouting method

一种地下管道、高聚物膜的技术,应用在下水管道系统、填方、管元件等方向,达到节约工期、防止二次沉降、节省造价的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The present invention will be further described in conjunction with the accompanying drawings.

[0036] (1) Use pipeline closed-circuit television inspection technology (CCTV) to conduct a comprehensive detection of underground pipelines to determine the location of the settlement pipe section and the settlement amount.

[0037] (2) Drill film bag placement holes

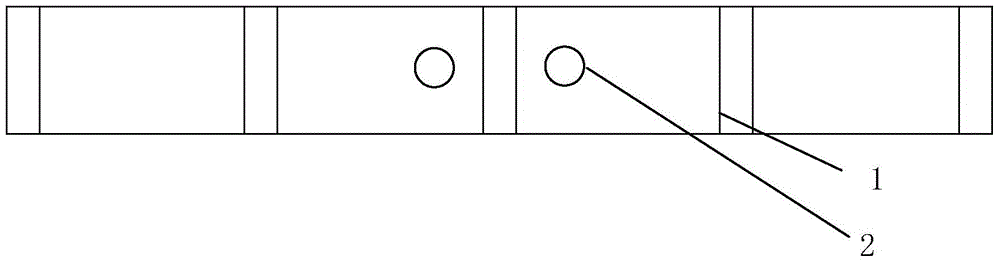

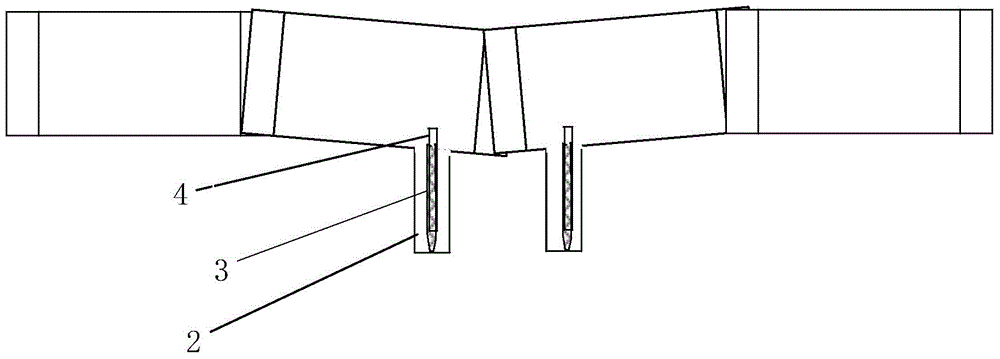

[0038] For the pipe section 1 that needs to be lifted, along the diameter direction of the end of the sinking section of the pipe, the holes 2 are drilled at intervals of 0.3-0.4m, such as figure 1 with figure 2 As shown, the pore diameter is about 5-12cm, and the pore depth is about 20-40cm.

[0039] (3) Place the film bag

[0040] Put the grouting pipe 4 into the opening end of the film bag 3, and fix the opening end of the film bag 3 on the grouting pipe 4 with a hoop. The length of the film bag should be greater than the hole depth. Generally, the diameter is 10-40cm, and the length is 30-60cm. Put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com