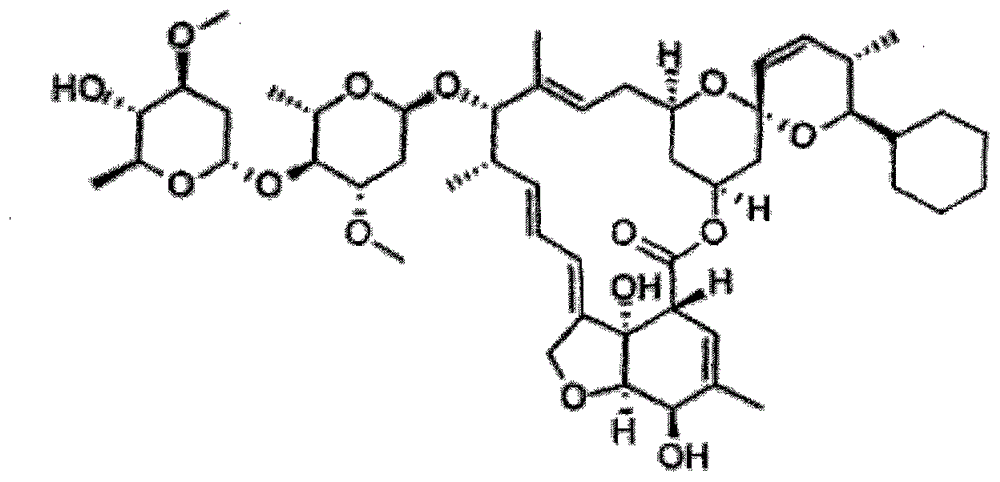

Method for preparing doramectin

A technology of doramectin and inoculum amount, which is applied in the field of doramectin preparation, can solve the problems of low fermentation yield and slow industrialization process, and achieve high fermentation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Strain: strain Streptomyces avermitilis XJ-8-115, screened and preserved by the Academy of Sciences of the State Grain Administration.

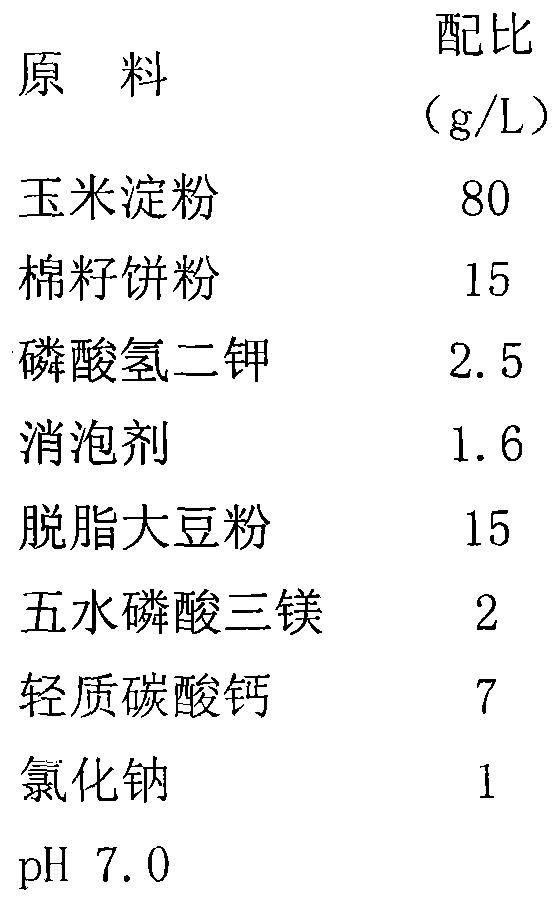

[0029] Doramectin Fermentation Medium

[0030]

[0031] Prepare 350L of fermentation medium and sterilize at 121-123°C for 20 minutes. The inoculum volume is 10%. After inoculation, the tank temperature is 28.0±0.5°C, the tank pressure is 0.04MPa, and the flow rate is 25m 3 / hr at a rotational speed of 80 rpm for 228 hours.

[0032] Feeding strategy: add the precursor cyclohexyl carboxylate twice, the first addition of cyclohexyl carboxylate is added after 40 hours of fermentation, and the supplementary amount is 1.0g / L; the second addition of cyclohexyl carboxylate Salt was added in 180 hours of fermentation, and the supplementary amount was 0.6g / L.

[0033] Add maltodextrin as feeding sugar in the middle and late stages of fermentation, and control the total sugar at 2.5-4.5%; the final tank unit is 773 mg / L. Cyclohexyl format...

Embodiment 2

[0035] Strain: strain Streptomyces avermitilis XJ-8-115, screened and preserved by the Academy of Sciences of the State Grain Administration.

[0036] Doramectin Fermentation Medium

[0037]

[0038] Prepare 350L of fermentation medium and sterilize at 121-123°C for 20 minutes. The inoculum volume is 10%. After inoculation, the tank temperature is 28.0±0.5°C, the tank pressure is 0.04MPa, and the flow rate is 25m 3 / hr at a rotation speed of 80 rpm for 312 hours.

[0039] Maltodextrin is added as feed sugar in the middle and late stage of fermentation, and the total sugar is controlled at 2.5-4.5%.

[0040] Feeding strategy: (1) Experiment 1: The precursor cyclohexyl carboxylate was added twice, the first addition of cyclohexyl carboxylate was added after 40 hours of fermentation, and the supplementary amount was 1.0g / L; the second The second addition of cyclohexyl formate was added at 180 hours of fermentation, and the additional amount was 0.6 g / L.

[0041] (2) Test 2...

Embodiment 3

[0048] Strain: strain Streptomyces avermitilis XJ-8-115, screened and preserved by the Academy of Sciences of the State Grain Administration.

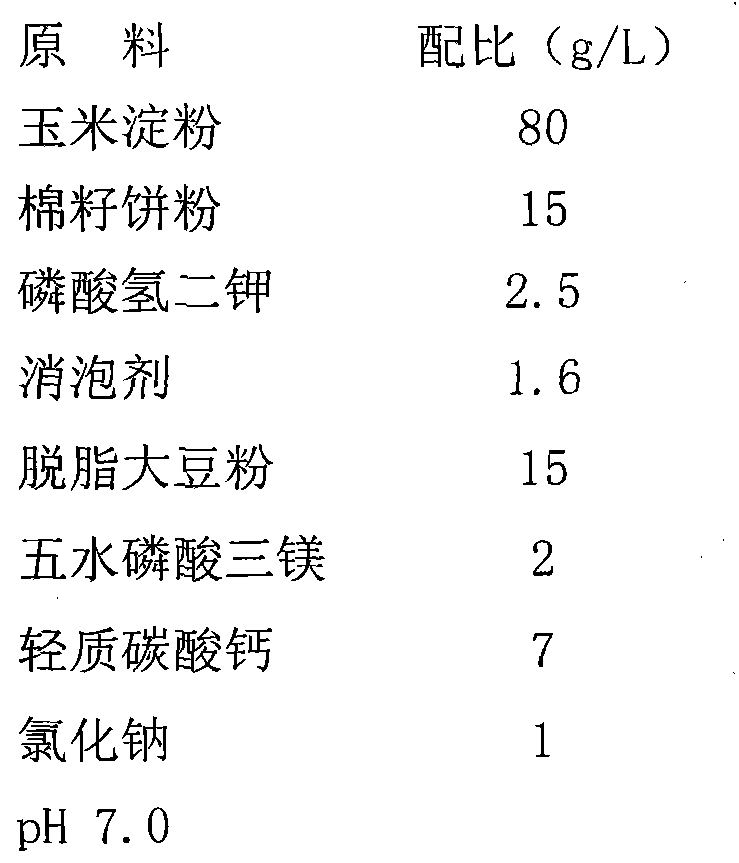

[0049] Doramectin Fermentation Medium

[0050]

[0051] Prepare 350L of fermentation medium and sterilize at 121-123°C for 20 minutes. The inoculum volume is 10%. After inoculation, the tank temperature is 28.0±0.5°C, the tank pressure is 0.04MPa, and the flow rate is 25m 3 / hr at a rotation speed of 80 rpm for 312 hours.

[0052] Maltodextrin is added as feed sugar in the middle and late stage of fermentation, and the total sugar is controlled at 2.5-4.5%.

[0053] Feeding strategy: Add the precursor cyclohexyl carboxylate twice, the first addition of cyclohexyl carboxylate is added at T hours of fermentation, and the supplementary amount is 0.8g / L; the second addition of cyclohexyl carboxylate Salt was added in 180 hours of fermentation, and the additional amount was 0.8g / L. The results are shown in Table 2.

[0054] Table 2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com