A visbreaking heat residence time estimation method and reaction device

A visbreaking and residence time technology, which is applied in measuring devices, cracking, non-catalytic thermal cracking, etc., can solve the problems of inestimable thermal residence time, meet the needs of scientific research and production, optimize and improve equipment, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

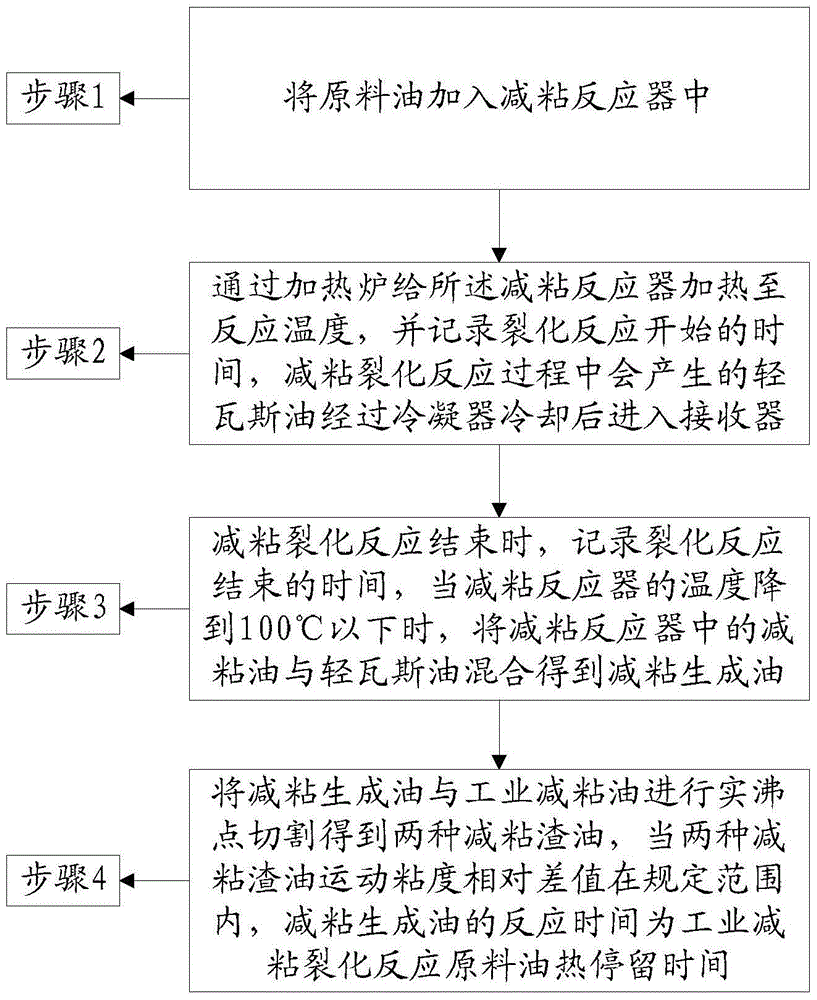

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a method for estimating the thermal residence time of visbreaking, and the estimating method includes:

[0030] Step 1: adding feedstock oil into the visbreaking reactor, the feedstock oil is the same as the feedstock oil used in industrial visbreaking reactions;

[0031] Step 2: Heat the vis-reducing reactor to 350°C at a rate of 1-5°C per minute through the heating furnace, because when the reaction temperature is not higher than 350°C, the raw material oil will not undergo fission reaction, and then continue to reduce the viscosity. Heat the visbreaking reactor so that the temperature of the visbreaking reactor rises rapidly to the inlet temperature of the industrial visbreaking reaction tower within 1 to 3 minutes, and record the initial time when the visbreaking reaction starts. At the same time, the visbreaking reactor The reaction pressure in the tank is controlled at 0-0.2MPa, light gas...

Embodiment 2

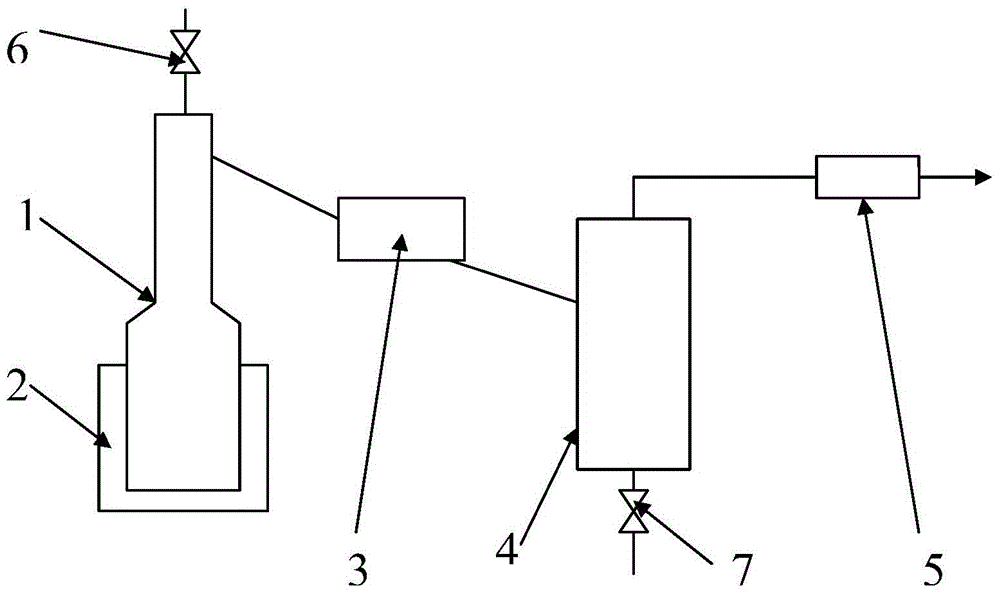

[0036] Such as figure 2 As shown, the embodiment of the present invention provides a visbreaking reaction device, which includes: a visbreaking reactor 1, a heating furnace 2, a condenser 3, a receiver 4 and a pressure controller 5. The viscous reactor 1 is arranged above the heating furnace 2, and the heating furnace 2 is used to heat the visbreaking reactor 1, the visbreaking reactor 1, the condenser 3 and the receiver 4 are connected internally, and the pressure controller 5 is arranged above the receiver 4 When working, the light gas oil in the visbreaking reactor 1 enters the receiver 4 through the condenser 3, and the noncondensable gas in the receiver 4 is discharged through the pressure controller 5.

[0037] Further, the visbreaking also includes a pressure supplement port 6 , and the pressure supplement port 6 is arranged on the upper part of the visbreaking reactor 1 .

[0038] Further, the visbreaking device also includes a light gas oil outlet 7, and the light g...

Embodiment 3

[0041] Such as figure 1 As shown, the embodiment of the present invention provides a method for estimating the thermal residence time of visbreaking, and the estimating method includes:

[0042] A tower-type visbreaking unit in a refining and chemical company, the inlet temperature of the reaction tower is 370°C, the outlet temperature is 360°C, the pressure is 0.7MPa, the mass ratio of water injection to raw oil is 0.7:100, the cold retention of raw oil in the reaction tower The time is 90 minutes, the properties of the raw material oil are shown in Table 1, and the kinematic viscosity of the raw material oil at 100°C is 781.4mm 2 / s, the kinematic viscosity at 100°C of the normal pressure industrial visbroken residue oil above 350°C produced after the real boiling point cutting of the industrial visbreaking oil is 600.5mm 2 / s.

[0043] Add the same raw material oil used in the above reaction into the reactor, control the reaction pressure in the reactor to 0MPa, turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com