Three-direction transfer mechanical clamp of water heater package clamping transfer machine

A technology for transfer machines and water heaters, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of reduced work efficiency, workers unable to bear the workload, heavy water heaters, etc., to achieve convenient maintenance, simple and practical design structure, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0014] see Figure 1 to Figure 5 , the embodiment of the present invention includes:

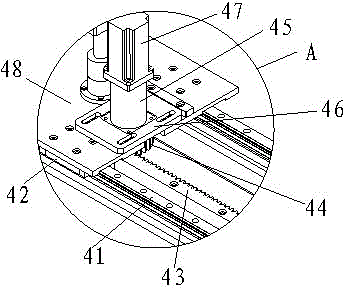

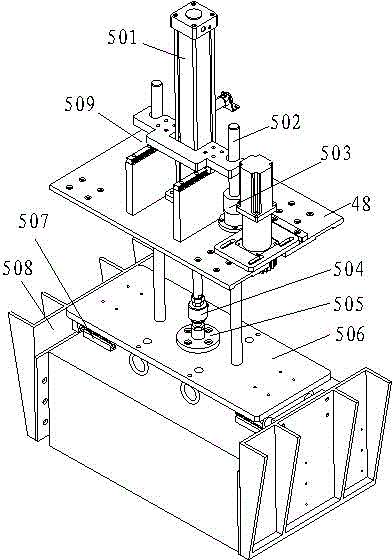

[0015] A three-direction transfer mechanical clamp of a water heater clamp transfer machine, the three-direction transfer mechanical clamp of the water heater clamp transfer machine includes a contour pad 40, a slide rail 41, a slider 42, a rack 43, and a gear 44. Reducer 45, reducer mounting plate 46, servo motor 47, moving base plate 48, mechanical limiter 49 and lift and traverse clamp 50, two parallel contour pads are installed on the welded frame 51, equal height A slide rail 41 is respectively installed on the pad bar 40, and two slide blocks 42 are provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com