Method for dismounting decollation bolt

A technology of bolts and screw holes, which is applied in the field of taking out broken threaded parts, can solve problems such as easily damaged screw holes, and achieve the effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

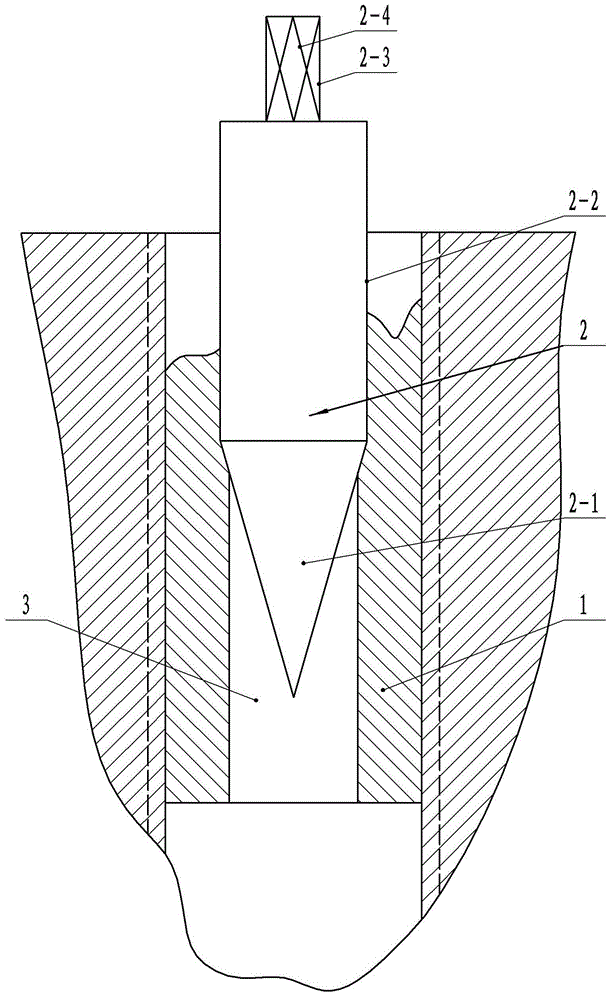

[0013] figure 1 Shown is a schematic diagram of the triangular scraper driven into the dead bolt in the method of removing the dead bolt. The removal steps of the dead bolt remaining in the screw hole of the equipment are as follows:

[0014] A. In the center of the broken bolt remaining in the screw hole, an inner through hole is drilled in the axial direction, and the diameter of the inner through hole is smaller than the thread root diameter of the broken bolt;

[0015] B. Prepare a triangular scraper. The outer diameter of the triangular scraper is larger than the diameter of the inner through hole and smaller than the diameter of the thread root of the broken bolt. The front end of the blade is tapered to the tip of the blade, and the end of the blade is a handle integrally formed with the blade. , the knife handle is a square cylinder, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com