Simulation transporting and loading toy truck

A technology for a toy car and a control device, applied in toy cars, toys, entertainment and other directions, can solve the problems of not meeting children's play needs, not having automatic dumping, lack of realism, etc., to enhance playability and fun, Realistic, fun effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

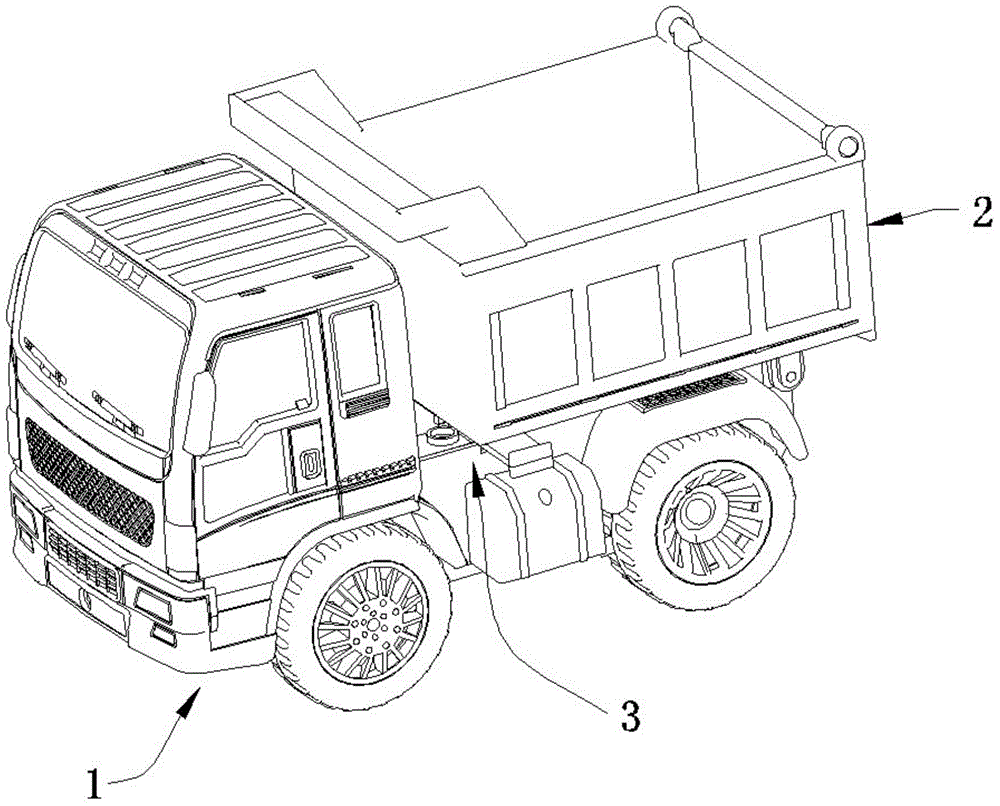

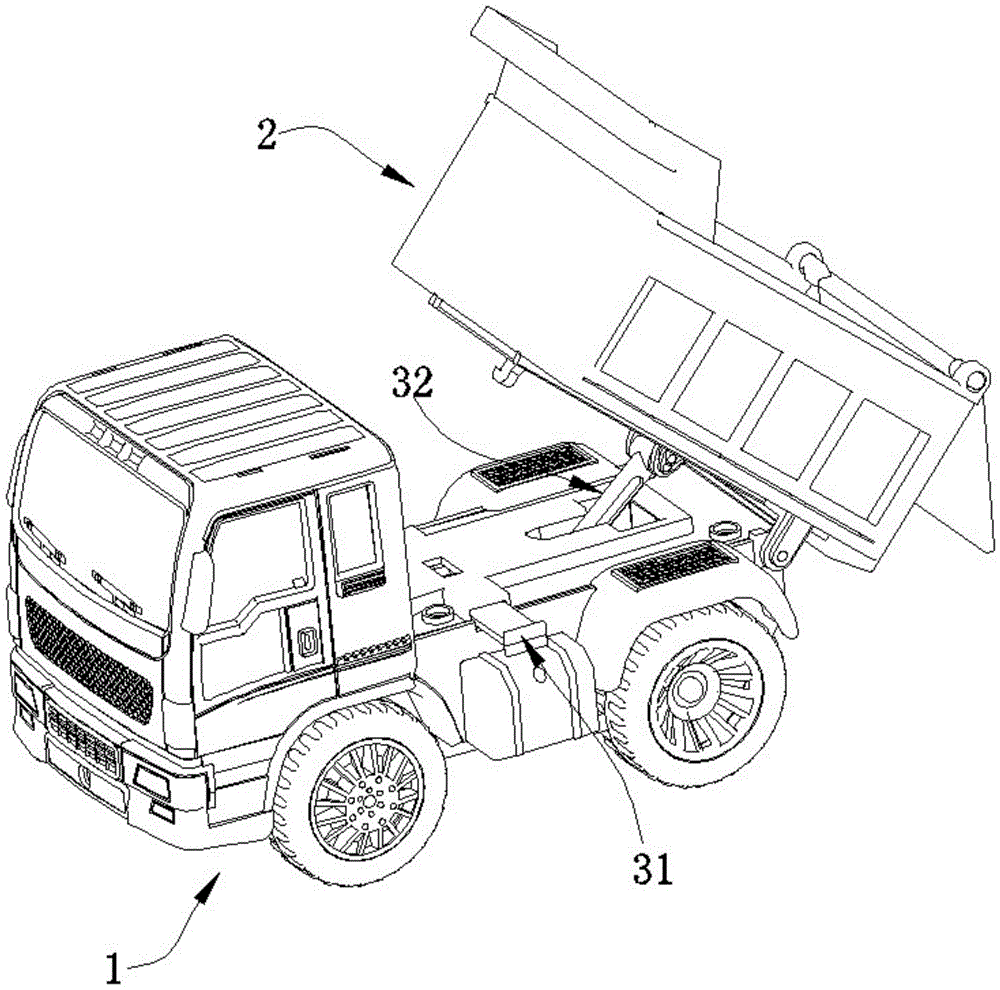

[0019] Examples, see Figure 1 to Figure 4 , a toy car for simulating transportation and loading, which includes a car body 1 and a bucket body 2, one end of the bucket body 2 is hinged on the car body 1, and corresponding to the car body 1, there is a The bucket body 2 is described as an automatic bucket unloading device 3 that makes it overturn around the hinge shaft.

[0020] The automatic dumping device 3 includes a control device 31 and a tipping mechanism 32 .

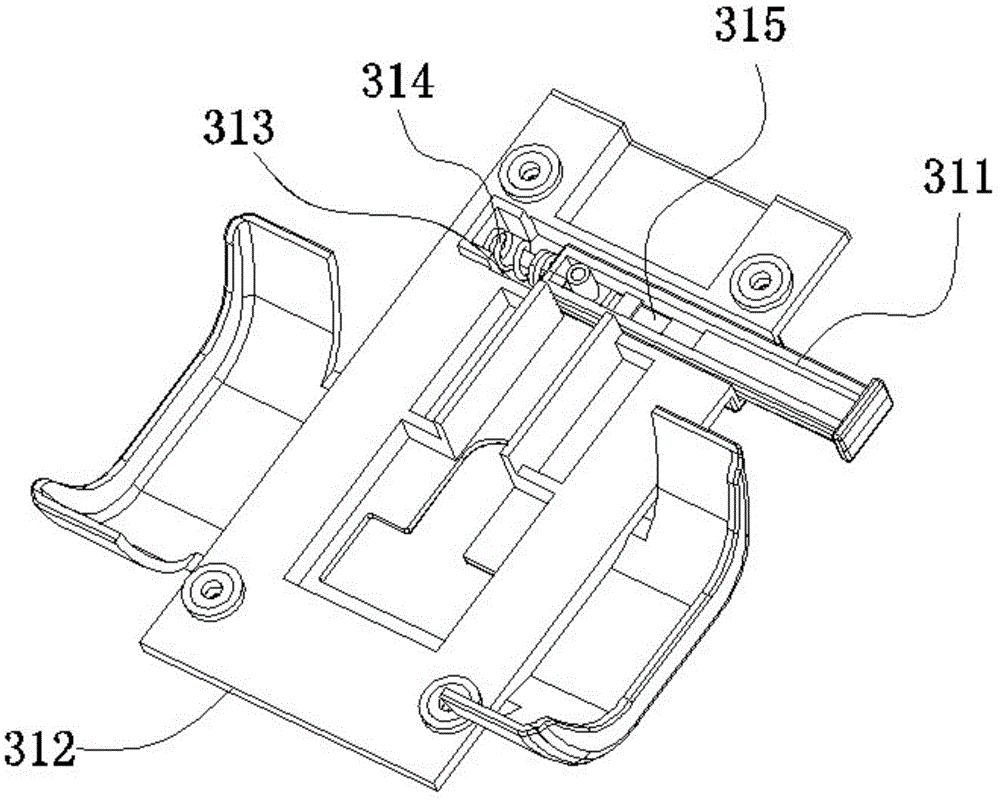

[0021] The control device 31 includes a push rod 311 and a cover plate 312, the bottom surface of the cover plate 312 is provided with a slot 313 adapted to the profile of the push rod 311, the push rod 311 is inserted into the plug Groove 313, and its first end is provided with a back-moving spring 314 and the side wall of described slot 313 conflicts, and middle part is provided with a hook position 315, and is provided with on this bucket body 2 and described bucket correspondingly After the car body 1 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com