Composite waterproof material with electrothermal function and preparation method thereof

A technology of electrothermal heating and waterproof material, applied in heating element materials, electric heating devices, ohmic resistance heating, etc., can solve problems such as increasing construction costs and affecting the heating effect of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1. Electrothermal waterproof membrane

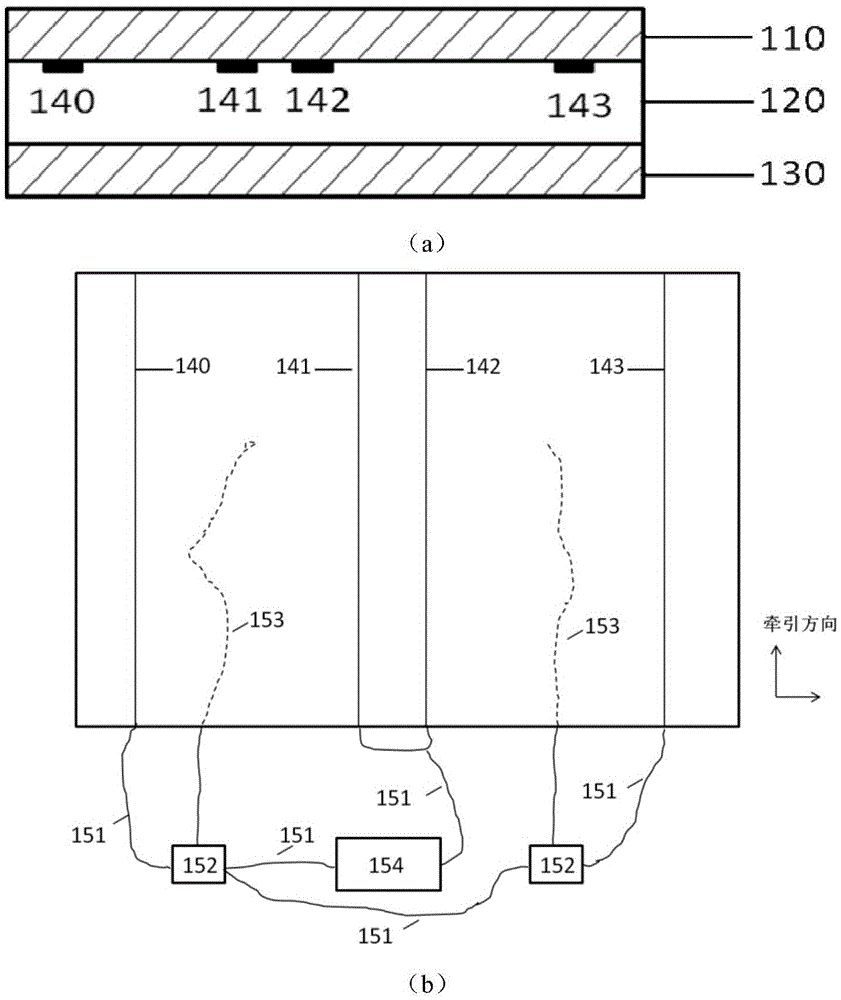

[0083] This embodiment discloses an electrothermal waterproof coiled material with a thickness of 2.0mm and a width of 5m. The electrothermal waterproof membrane has a sheet-like structure, such as figure 1 As shown in (a), from top to bottom are: waterproof base material layer 110, electrothermal layer 120 and waterproof base material layer 130; Four cut-off bars 140 , 141 , 142 and 143 are arranged between the electrothermal layers 120 .

[0084] Both the waterproof base material layer 110 and the waterproof base material layer 130 are PVC base materials, and their thicknesses are 0.65 mm and 0.55 mm respectively, and the middle is an electric heating layer 120 with a thickness of 0.8 mm; the waterproof base material layer 110 and the waterproof base material layer 130 are used The PVC substrates of all the products adopt the same formula, and the composition in parts by weight is: 100 parts of PVC resin, 50 parts of ...

Embodiment 2

[0088] Example 2, electrothermal waterproof membrane

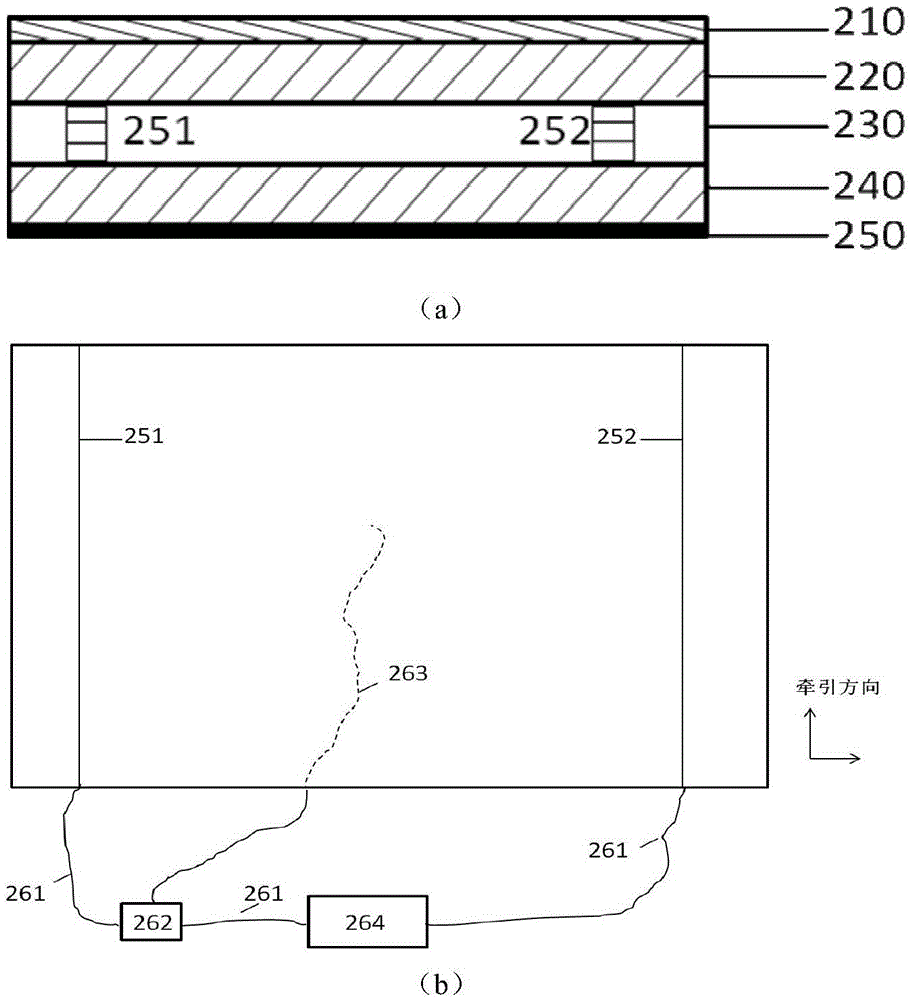

[0089] This embodiment discloses an electrothermal waterproof coiled material provided with non-woven fabric, with a thickness of 7.0 mm and a width of 1.2 mm. The electrothermal waterproof membrane has a sheet-like structure, such as figure 2 As shown in (a), from top to bottom are: shale layer 210, waterproof substrate layer 220, electric heating layer 230, waterproof substrate layer 240 and PE film 250, electric heating layer 230 is composed of electric heating material and non-woven fabric, electric heating Two cut-off bars 251 and 252 are provided in the layer.

[0090] The waterproof base material layer 220 and the waterproof base material layer 240 are SBS modified asphalt coating material layers, both of which have a thickness of 2.0mm. The composition in terms of mass percentage is: 90# asphalt: 30%, 10# asphalt 20%, SBS: 4%, motor oil 10%, talc 36%. A shale layer 210 with a thickness of 0.97 mm is provided ab...

Embodiment 3

[0093] Embodiment 3, electrothermal waterproof membrane

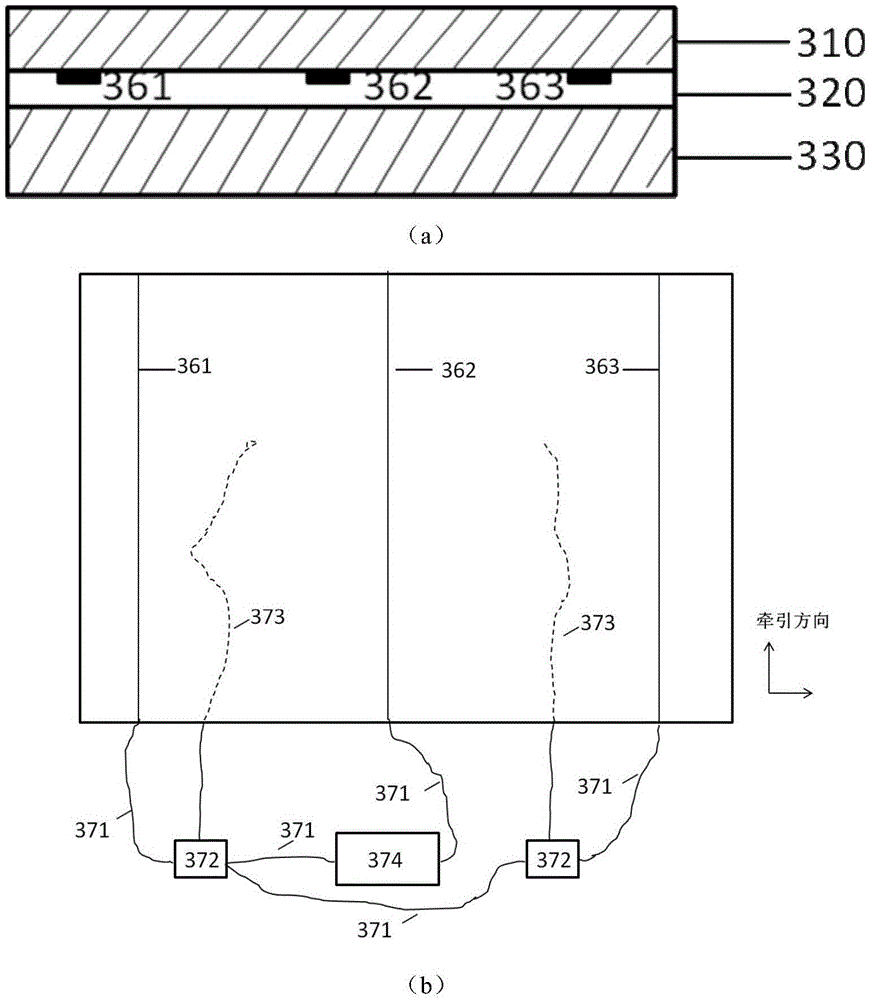

[0094] This embodiment discloses an electric heating waterproof roll material provided with grid cloth, the thickness is 1.52mm, and the width is 2m. The composite waterproof material with electrothermal function is a lamellar structure, such as image 3 As shown in (a), from top to bottom are: waterproof base material layer 310, electric heating layer 320 and waterproof base material layer 330, electric heating layer 320 is made of electric heating material and grid cloth, waterproof base material layer 310 and electric heating layer 320 There are three cut-off bars 361, 362 and 363 between them.

[0095] Both the waterproof base material layer 310 and the waterproof base material layer 330 are TPO base materials with a thickness of 0.55 mm and 0.75 mm respectively, and are composed of the following components in parts by weight: 100 parts of TPO resin, 30 parts of magnesium hydroxide, 3 parts of titanium dioxide 2 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com