ZnO/ZnS/FeS 2-core-shell structure array film and preparing method

A technology of core-shell structure and film, which is applied in the field of ZnO/ZnS/FeS2 core-shell structure nanorod array film and its preparation, can solve the problems of not being able to absorb visible light, limit the utilization rate of sunlight, etc., and achieve improved light absorption and light response performance , good light absorption and light response performance, and high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

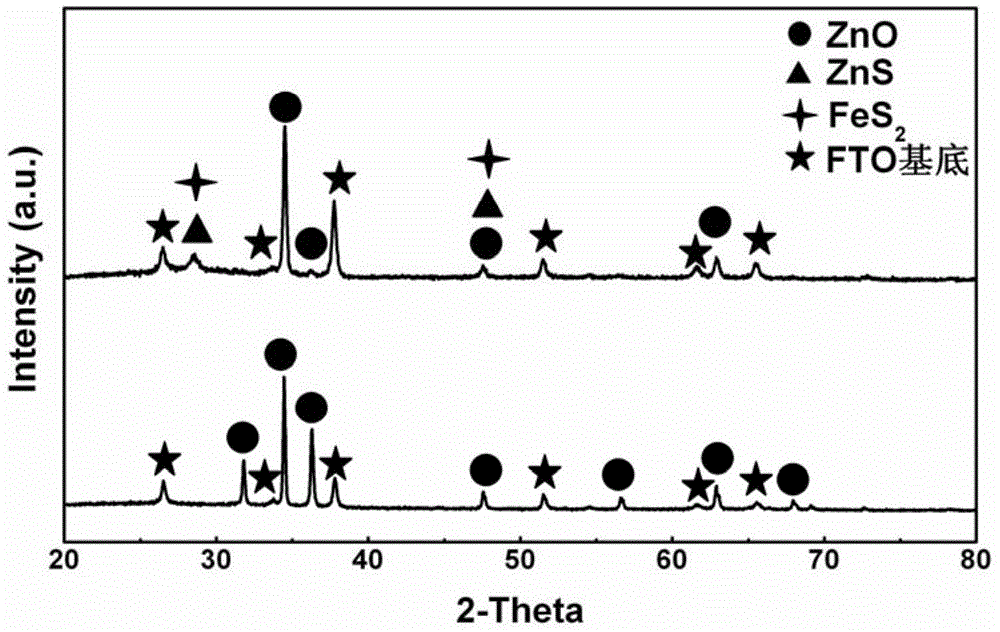

[0031] With reference to accompanying drawing, further illustrate the present invention:

[0032] ZnO / ZnS / FeS 2 A method for preparing a core-shell structure array film, comprising the following steps:

[0033] 1) Use FTO conductive glass as the substrate, perform ultrasonic cleaning in acetone, absolute ethanol, and deionized water for 15 minutes, and dry the cleaned substrate for later use;

[0034] 2) Dissolve zinc acetate dihydrate in a mixed solution of ethylene glycol methyl ether and ethanolamine, the molar ratio of ethanolamine to zinc ions is 1:1, and dissolve the mixed solution of zinc acetate dihydrate, ethylene glycol methyl ether and ethanolamine at 60 Stir magnetically at ℃ until the zinc acetate dihydrate dissolves completely, forming a uniform and transparent seed layer solution;

[0035] 3) Immerse the substrate in the seed layer solution at room temperature, pull up the coating at a speed of 200 mm / min, dry the coated substrate at 80°C, repeat the above ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com