Parallel flow evaporator applied to automobile air conditioner

An automobile air conditioner and parallel flow technology, which is applied in the field of automobile air conditioner evaporators and parallel flow evaporators, can solve the problems of small refrigerant flow, heat transfer efficiency that cannot meet the requirements, and refrigerant utilization rate is not high, so as to improve heat transfer efficiency , Compact structure, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

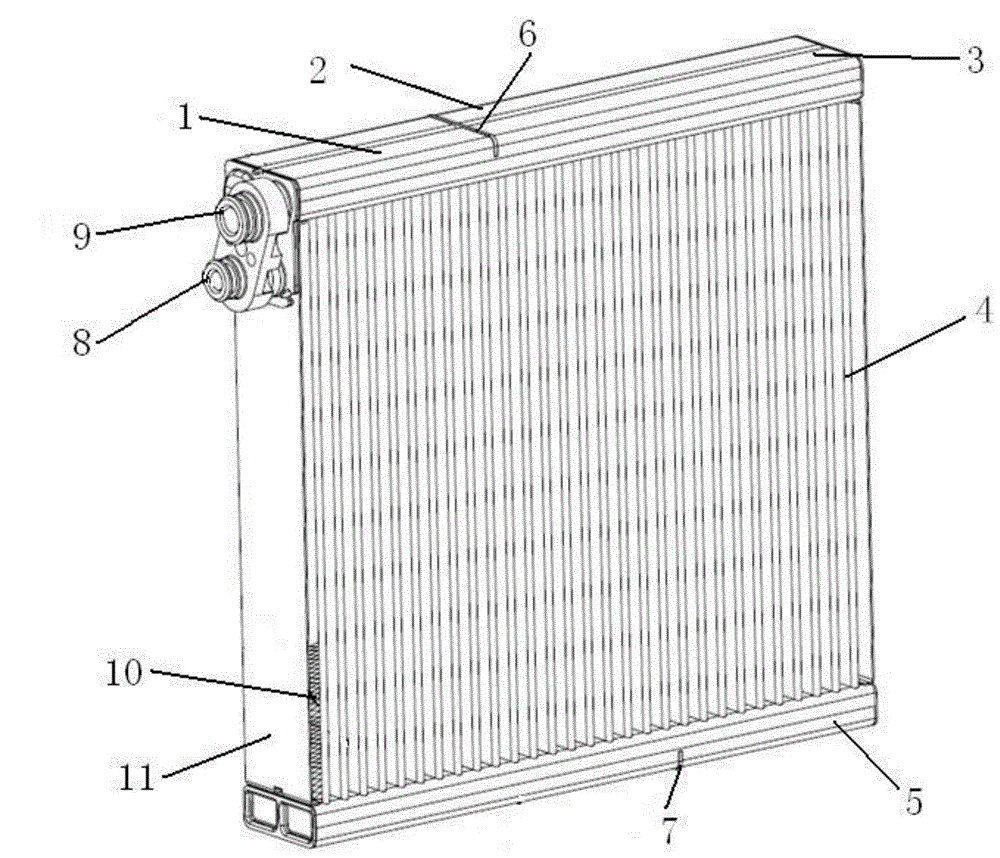

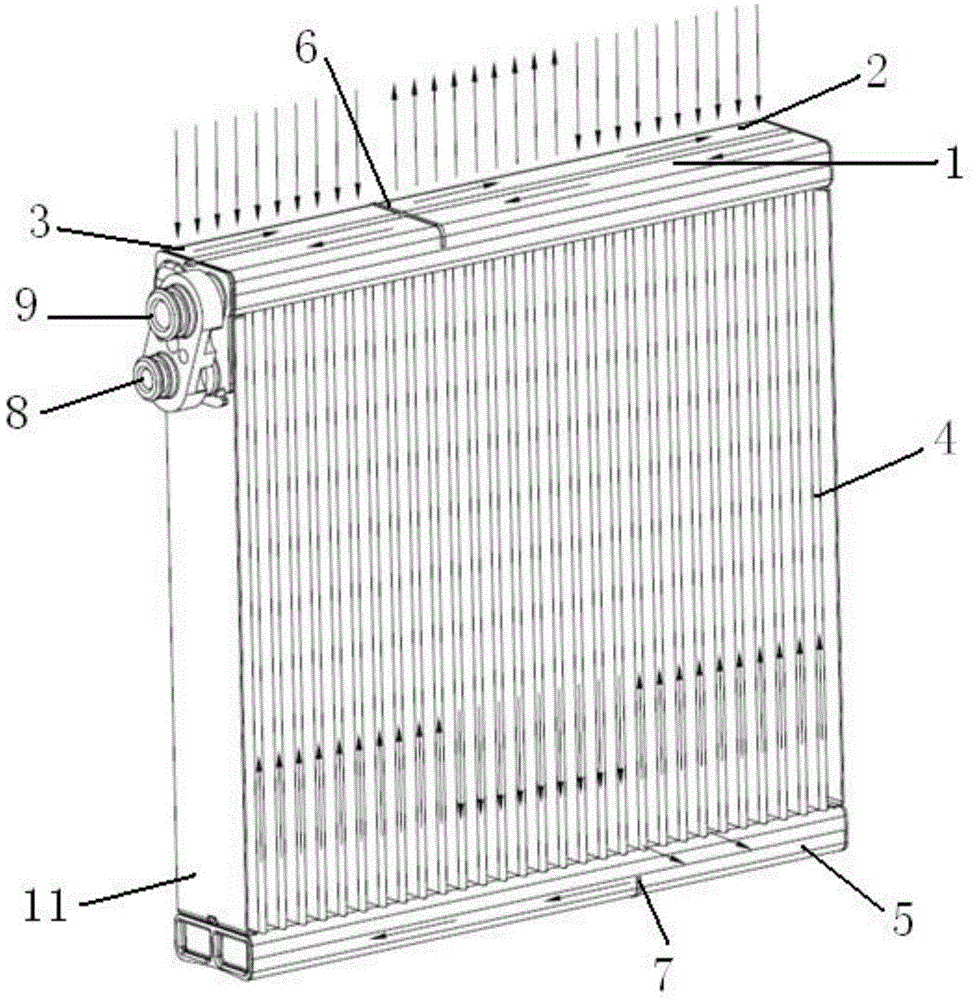

[0020] like figure 1 As shown, the present invention is a parallel flow evaporator applied to automobile air conditioners. The front heat exchange module 1 and the rear heat exchange module 2 are arranged in parallel. Both the front and rear heat exchange modules are composed of an upper evaporation chamber 3, a lower evaporation chamber 5 and It is composed of porous flat tubes 4 connected to the upper and lower evaporation chambers. The upper evaporation chamber 3 and the lower evaporation chamber 5 are equipped with several mounting holes for assembling the porous flat tubes 4. The porous flat tubes 4 are respectively installed in the upper evaporation chamber 3 and the lower end. The installation hole corresponding to the evaporation chamber 4. The partition a6 is placed at the front of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com