Intelligent well underground data collecting system based on high-temperature single-chip microcomputer

A technology of downhole data and acquisition system, applied in wellbore/well components, earthwork drilling, measurement, etc., can solve the problems of not widely used and slow development, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

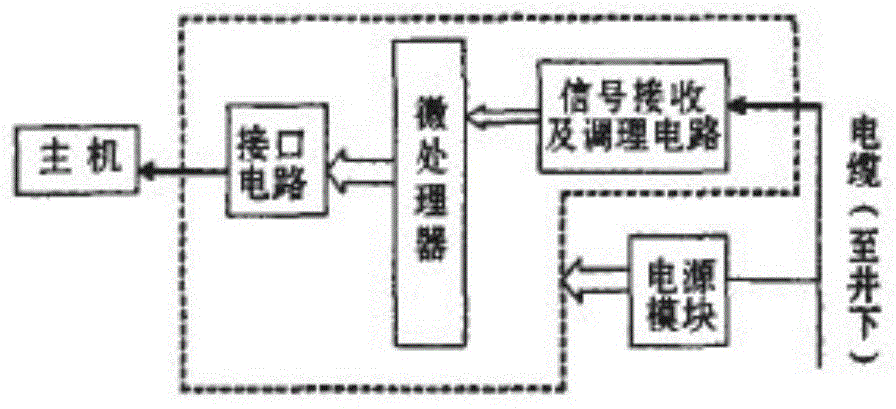

[0010] The intelligent downhole data acquisition system based on high-temperature single-chip microcomputer is composed of the downhole part and the surface part. The downhole part and the surface part are connected by a single-core steel armored cable. It is composed of the machine upload circuit and the system host; 220V AC is transmitted from the ground to the underground part through a long-distance cable to supply power. The sensor group includes temperature sensors, pressure sensors and displacement sensors. The signals of the sensor groups are conditioned and converted into voltage signals. The multiplexer HT506 selects and collects, and after being converted by the A / D converter HT574, it is transmitted to the microprocessor HT83C51, and the HJ389 high-temperature pulse synthesis signal long-line driver is used as the drive circuit to send to the cable; the data receiver uploads the HJ388 pulse in the circuit The signal preprocessing module performs signal conditioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com