Main beam cable-stayed suspension forming technological method for self-anchorage type suspension bridge

A technology of self-anchored suspension bridge and process method, applied in the direction of suspension bridges, bridges, bridge construction, etc., can solve the problems of artificial input, unimplementation of navigation, inability to implement, etc., and achieves reduction of construction costs, good application prospects, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

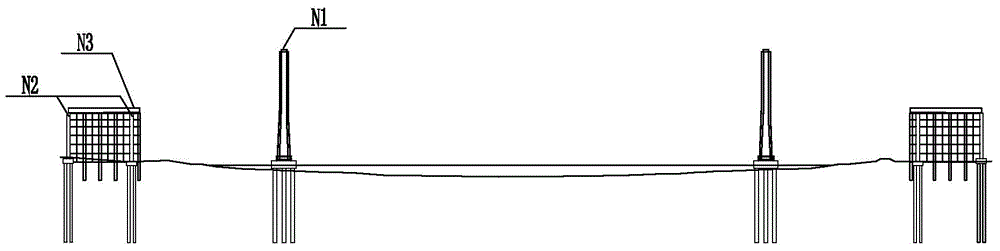

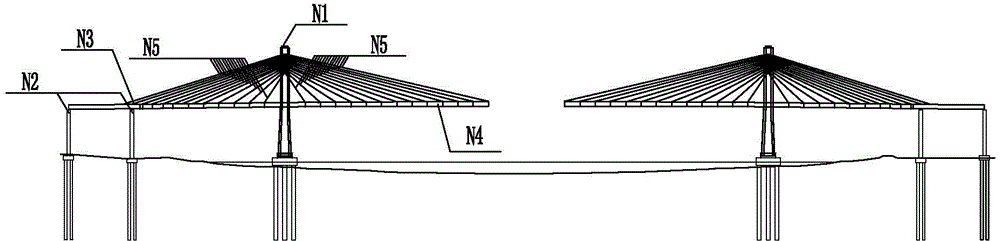

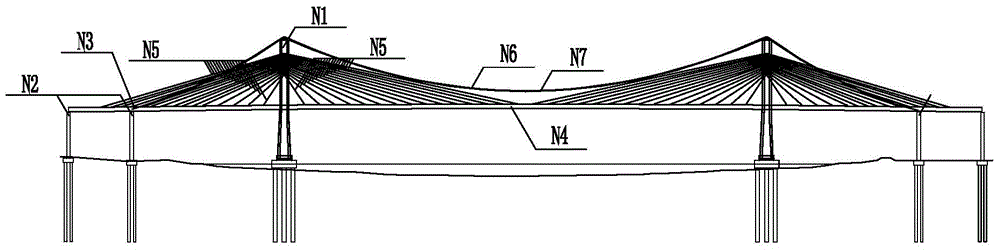

[0042] Such as Figure 1 to Figure 5 Shown is the entire construction process of the main girder cable-stayed suspension beam forming process of the self-anchored suspension bridge, including the following steps:

[0043] (1) The bridge foundation construction is completed by using the bored pile construction technology; the cap platform construction is completed by the double-wall steel cofferdam construction technology; the pier N2 and bridge tower N1 construction is completed by the turned-over construction technology; the edge is completed by the cast-in-place construction technology. For the construction of the cast-in-place span section N3, the construction of the bridge foundation, cap, pier N2, bridge tower N1 and side-span cast-in-place section N3 will be completed in sequence;

[0044] (2) Install the steel main girder N4 and temporary stay cable N5 section by section from the near tower to the mid-span direction. The steel main girder has good overall strength and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com