An anti-coke clogging device in a dry quenching furnace

A CDQ furnace and coke technology, which is applied in furnace safety devices, coke cooling, coke ovens, etc., can solve problems such as coke blockage and collapse, and achieve the effect of smooth discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

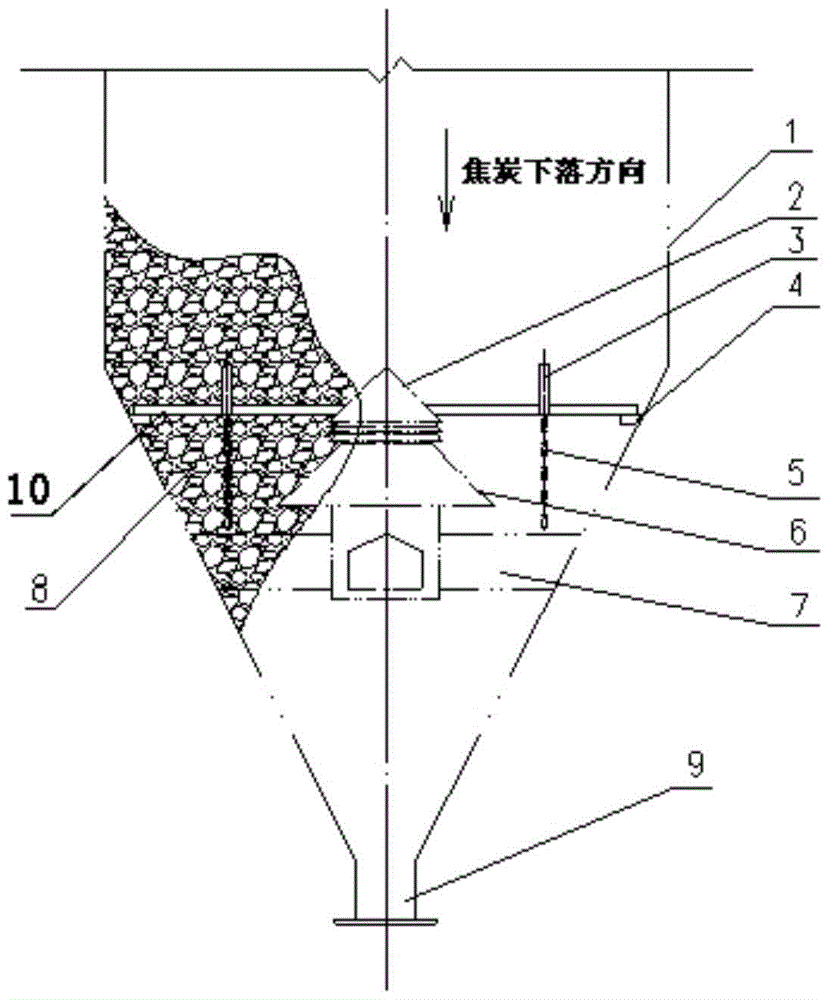

[0019] See figure 1 , figure 2 , an anti-coke blockage device in the CDQ furnace. The CDQ furnace is provided with a hood composed of a small hood 2 and a large hood 6. The hood communicates with the air supply duct 7 arranged in the CDQ furnace cone. The anti-coke blockage device in the extinguishing furnace is arranged around the hood, including the blanking broken body 3, the blanking crushing support 10, and the dredging chain 5. The blanking and crushing support 10 is arranged between the CDQ furnace cone bucket and the air supply hood. The blanking broken body 3 is fixed on the blanking crushing support 10, and a plurality of dredging chains 5 hang below the blanking crushing support 10; when the coke layer 8 with a dense structure in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com