A Combined Water Treatment Method for Simultaneously Removing Sulfate, Hardness and Total Dissolved Solids

A technology of total dissolved solids and sulfate, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Excessive sulfate content and other problems, to achieve the effect of good promotion and application prospects, beneficial to human health, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

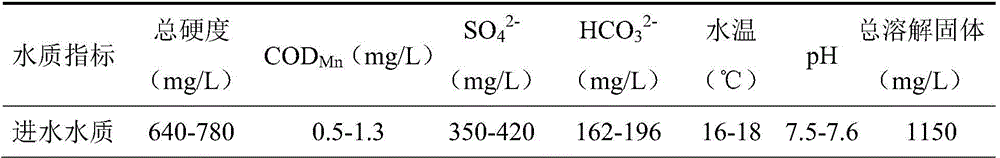

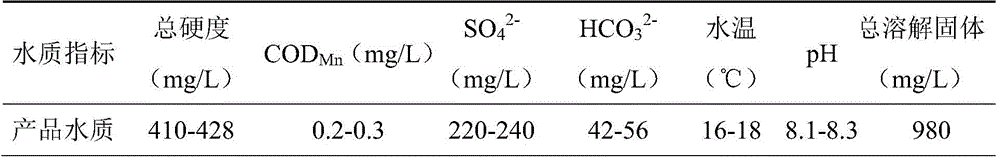

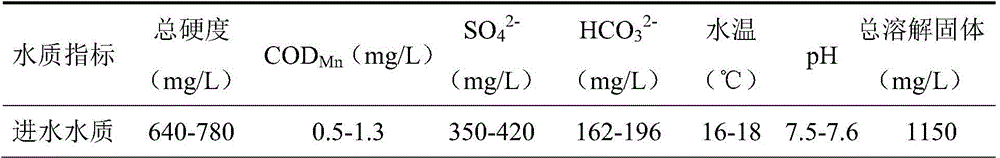

Embodiment 1

[0023] A combined water treatment method for the simultaneous removal of sulfate, hardness and total dissolved solids, comprising the following steps:

[0024] (1) Use special magnetic resin to remove sulfate in water, and obtain primary purified water through solid-liquid separation; among them, special magnetic resin is magnetic anion exchange resin, and its exchange group is bicarbonate; special magnetic resin removes sulfate in water The sulfate treatment process adopts the direction of upward flow; at the same time, synchronously extract the invalid resin and add the regenerated resin to keep the total capacity of the resin in the system relatively stable; the regeneration method of the special magnetic resin is: use sodium bicarbonate with a concentration of 5% Solution treatment for 45min;

[0025] (2) Add hardness-removing medicament to coagulate in the first-level purified water, contact and filter to remove sediment to obtain secondary purified water; wherein, the ha...

Embodiment 2

[0034] A combined water treatment method for the simultaneous removal of sulfate, hardness and total dissolved solids, comprising the following steps:

[0035] (1) Use special magnetic resin to remove sulfate in water, and obtain primary purified water through solid-liquid separation; among them, special magnetic resin is magnetic anion exchange resin, and its exchange group is bicarbonate; special magnetic resin removes sulfate in water The sulfuric acid treatment process adopts the upward flow direction; at the same time, the invalid resin is extracted synchronously and the regenerated resin is added to keep the total capacity of the resin in the system relatively stable; the regeneration method of the special magnetic resin is: use sodium bicarbonate with a concentration of 8% Solution treatment for 30min;

[0036] (2) Add hardness-removing medicament to coagulate in the first-level purified water, contact and filter to remove sediment to obtain secondary purified water; wh...

Embodiment 3

[0045] A combined water treatment method for the simultaneous removal of sulfate, hardness and total dissolved solids, comprising the following steps:

[0046] (1) Use special magnetic resin to remove sulfate in water, and obtain primary purified water through solid-liquid separation; among them, special magnetic resin is magnetic anion exchange resin, and its exchange group is bicarbonate; special magnetic resin removes sulfate in water The sulfate treatment process adopts the upward flow direction; at the same time, the invalid resin is extracted synchronously and the regenerated resin is added to keep the total capacity of the resin in the system relatively stable; the regeneration method of the special magnetic resin is: use sodium bicarbonate with a concentration of 10% Solution treatment for 15 minutes;

[0047] (2) Add hardness-removing medicament to coagulate in the first-level purified water, contact and filter to remove sediment to obtain secondary purified water; wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com