Stepping chip removing device

A chip removal device and step-by-step technology, applied in the field of step-by-step chip removal devices, can solve the problems of low chip removal efficiency and stuck waste, and achieve the effect of high chip removal efficiency and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

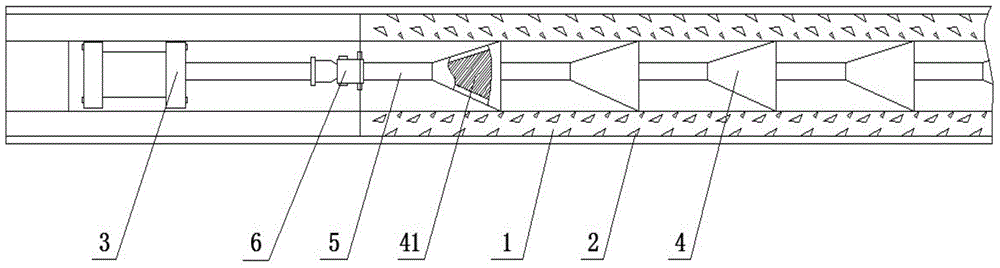

[0012] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

[0013] Such as Figure 1-2 As shown, the step-by-step chip removal device includes a chip removal box 1 that supports the entire device, and a number of barbs 2 are provided on the side walls on both sides of the device, and several chip removal boxes are placed in the middle of the chip removal box 1 4. Every two chip removal boxes 3 are connected by a connecting shaft 5, and the outermost connecting shaft 5 is connected to a hydraulic cylinder 3 through a connecting piece 6, wherein: an electromagnet 41 is arranged in the chip removal box 4, and then the When energized, the waste materials (such as strips, lumps, and rolls) in the chip removal box 1 can be adsorbed on the chip removal box 4. The electromagnet 41 is connected to the control system through the wires in the shaft 5. connect.

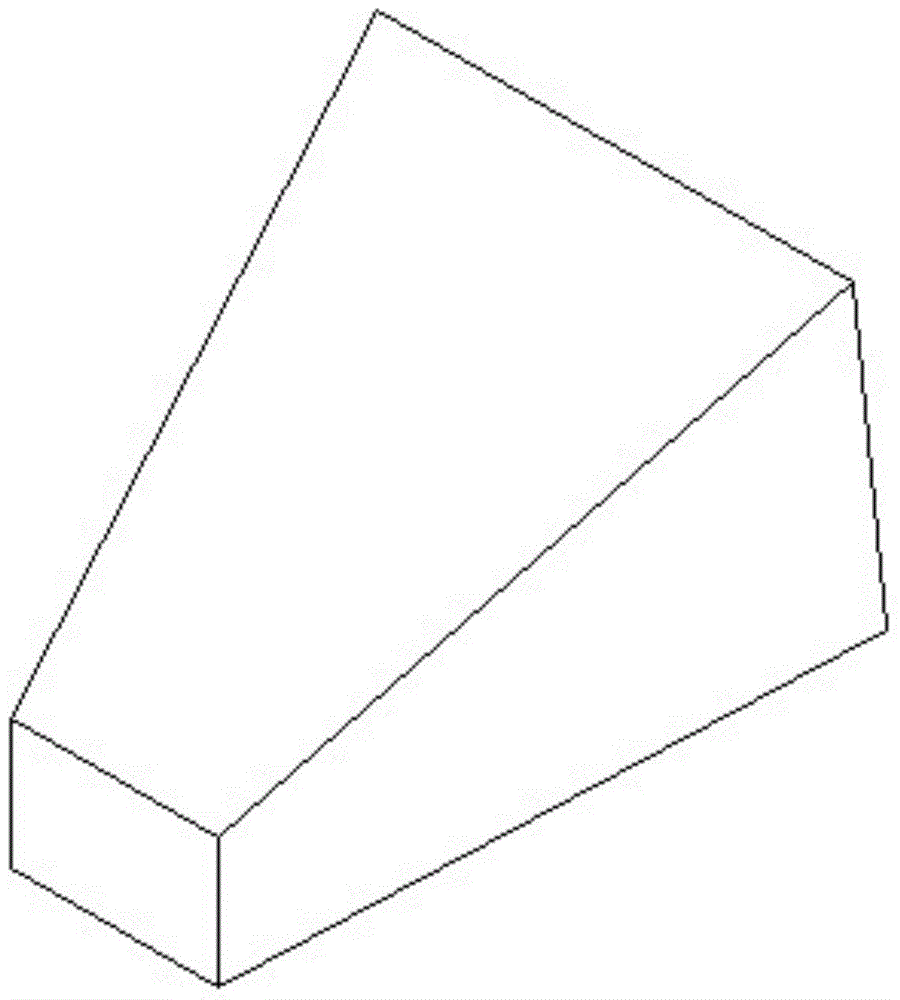

[0014] The chip removal box 4 is a conical block, and its large end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com