Self-loading scissor extrusion pull arm carriage

A carriage and boom technology, which is applied in the field of self-loading scissor extrusion pull arm carriages, can solve the problems of low efficiency of oil cylinder output, increase the labor of staff, and large length and size of compressors, etc., to achieve improved efficiency and simple structure , the effect of using a large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

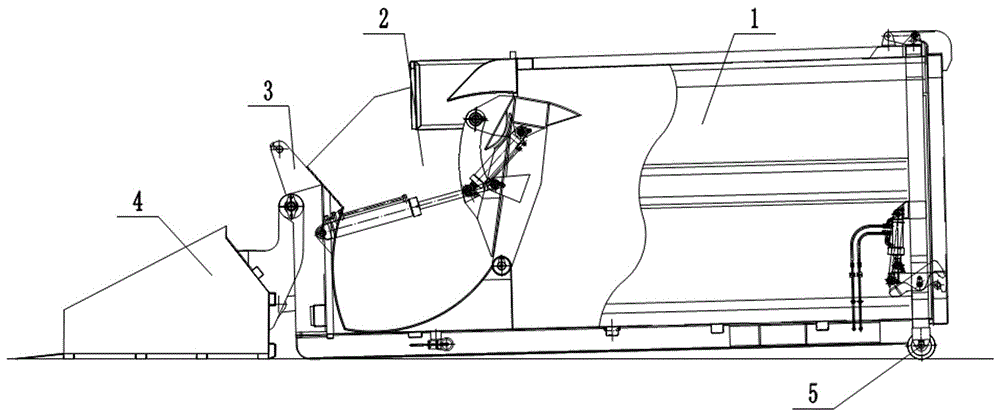

[0026] see as figure 1 As shown, the self-loading scissor extrusion pull arm carriage of the present invention includes a box body 1 for accommodating compressed materials, a compressor 2 with a built-in scissor extrusion device, a lifting hook 3, and a lifting hook with a double rocker structure. The feeder 4 and the roller 5; the compressor 2 is fixedly installed on the front part of the box body 1, and the front upper part is an inclined and open feeding port, and the lifting hook 3 used for the carriage to go up and down is fixed below the feeding port, and the compressor 2 A feeder 4 for collecting and lifting materials is installed in the front, and a roller 5 for walking is installed in the rear and lower part of the box body 1 .

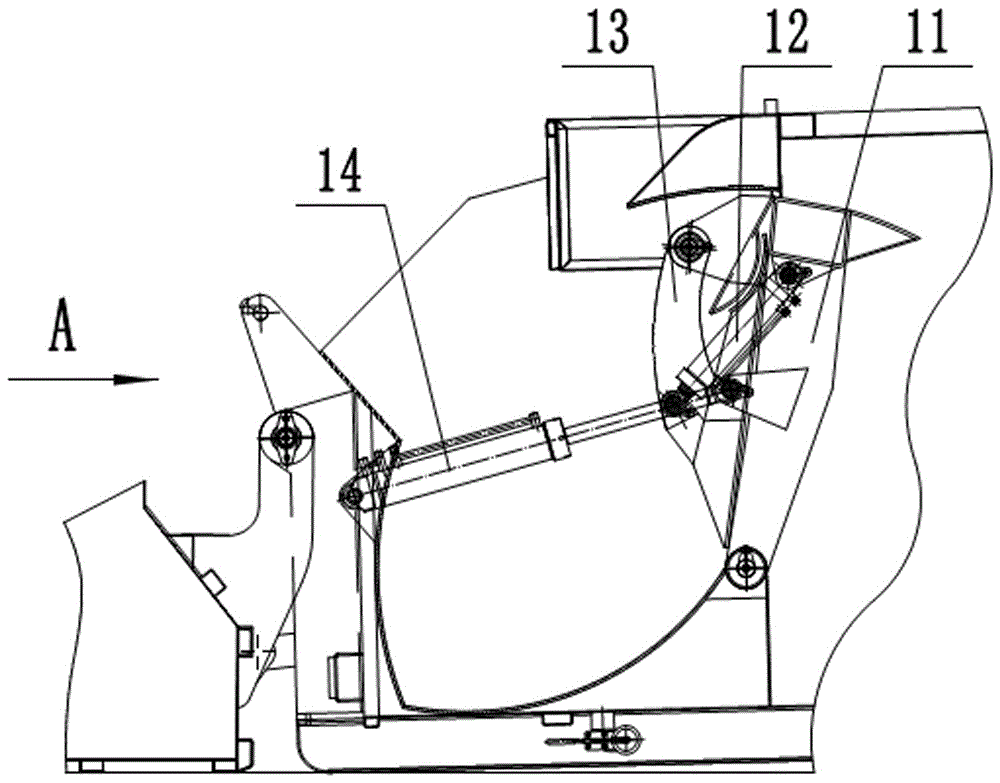

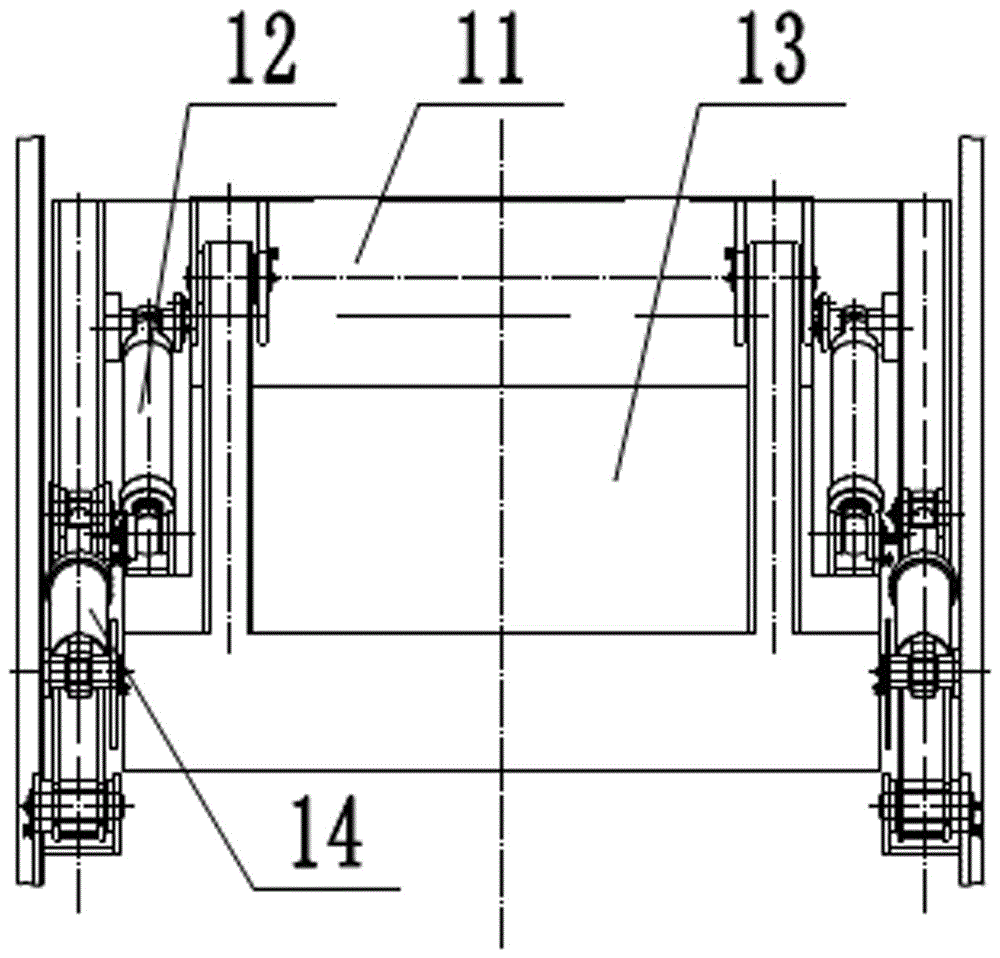

[0027] see as Figure 2-3 As shown, the compressor 2 described in the present invention includes a swing arm 11, a shearing cylinder 12, a shearing plate 13 and a swinging cylinder 14; The lower end of the swing arm 11 is hinged below the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com