A ready-to-drink beverage bottle with a built-in vertical material box

A beverage bottle and material box technology, which is applied to containers with multiple items, containers, transportation and packaging, etc., can solve the problems of poor public acceptance, inconvenience to drink with the mouth, difficult sealing problems, etc. The effect of easy processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

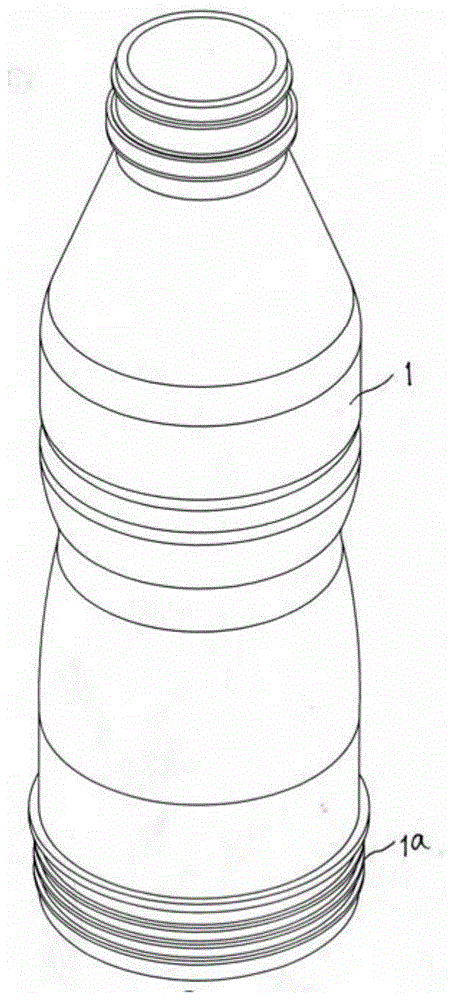

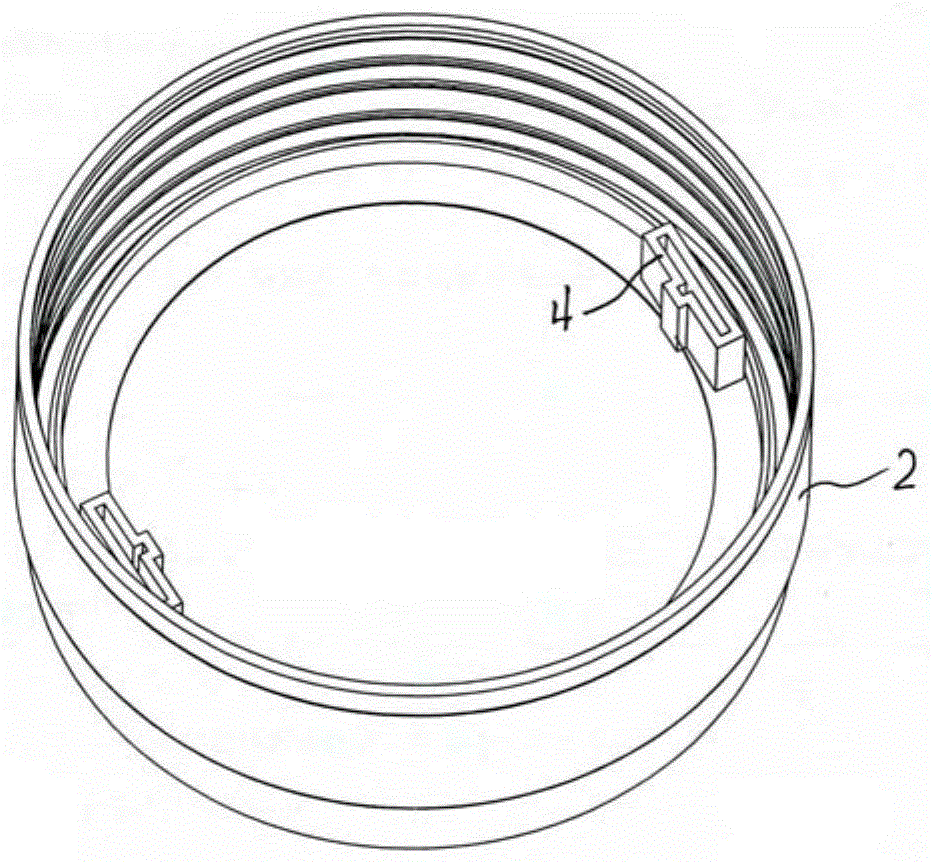

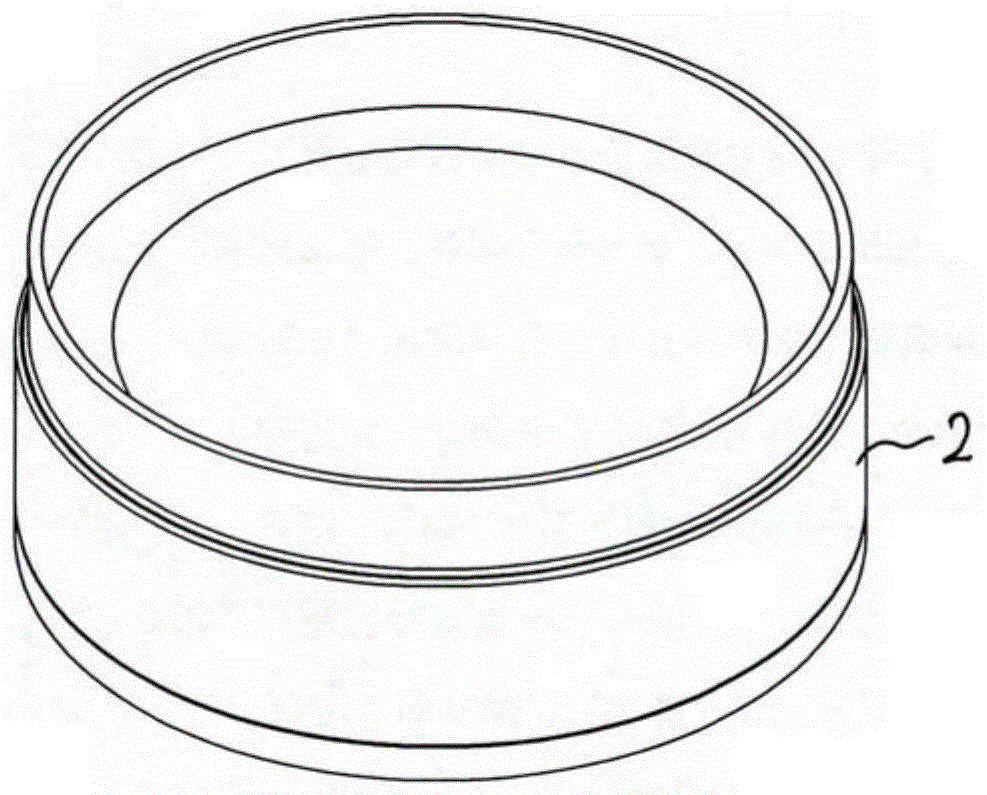

[0043] Beverage bottle is made up of bottle cap, bottle body, and bottle body is made up of upper bottle body 1 and lower bottle body 2 again. That is, the external thread 1a on the upper bottle body 1 is screwed with the internal thread 2a on the lower bottle body 2 (see figure 1 , Figure 5 ). see Figure 2 ~ Figure 6 , the bottle body is composed of an upper bottle body 1 and a lower bottle body 2 through screw connections; the bottom of the lower bottle body 2 has an elastic bottom surface 2b, and the elastic bottom surface 2b is convex arc-shaped or corrugated or flat-bottomed; The front half material box 5 and the rear half material box 6 are buckled together, the front half material box 5 is fixed on the inner surface of the front bottom plate 5a by the outer cylinder 5d, and the rear half material box 6 is fixed by the inner cylinder 6d Formed on the inner surface of the rear base plate 6a, the inner cylinder 6d of the rear half material box 6 has more than one circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com