A grinding head with controllable pressure distribution

A technology of pressure distribution and grinding head, which is applied in the direction of grinding head, manufacturing tools, surface polishing machine tools, etc., can solve the problem of uncontrollable pressure distribution of grinding head, and achieve the effect of improving the influence of edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

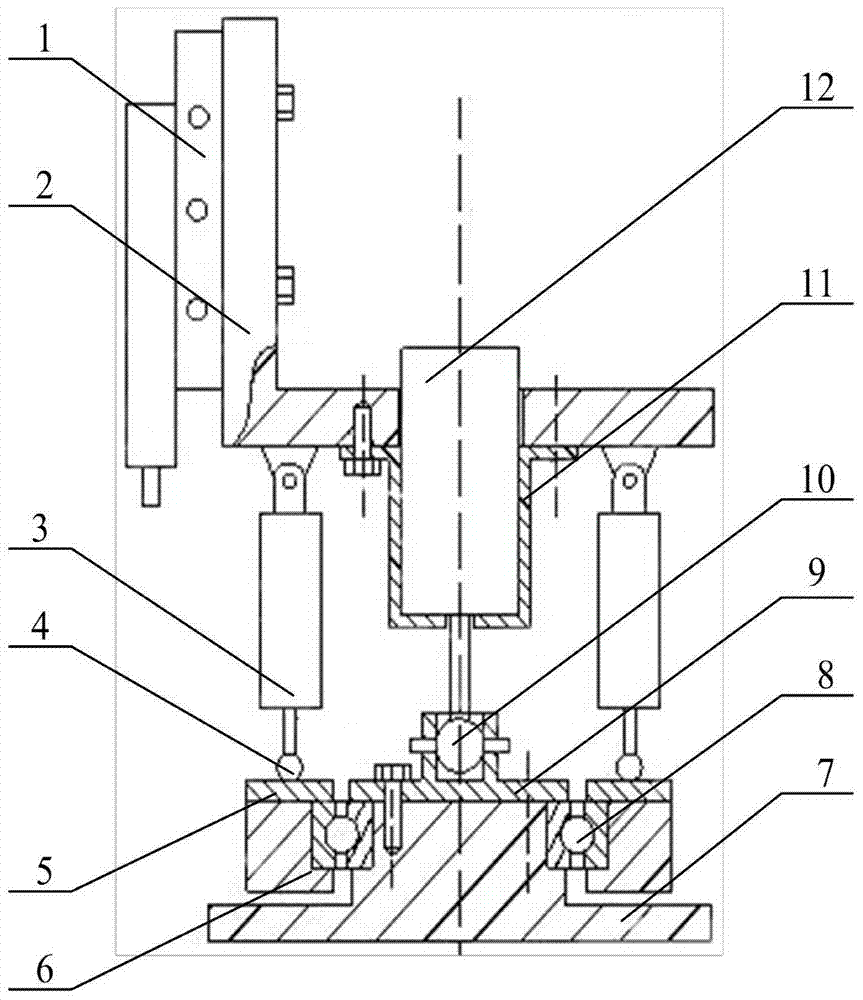

[0021] The difference between this embodiment and Embodiment 1 is that the three groups of cylinders 3 are evenly distributed on the bottom of the support 2, and the three groups of cylinders 3 are respectively equipped with pressure regulating valves and reversing valves, which can control the pressure distribution to change in various directions. One end of the cylinder 3 is connected on the support 2 by a hinge, and the direction of the axis of rotation of the hinge will be perpendicular to the connecting line between the motor 12 and the axis of the hinge, and the other end of the cylinder 3 is connected with the upper cover plate 5 of the bearing outer ring by a ball hinge. The diameter of the ball head 10 should be slightly smaller than the diameter of the cylinder hole, so that the ball head 10 can swing freely in the cylinder hole without a large gap, and the cylindrical pins at both ends of the ball head 10 are stuck in the grooves on both sides of the cylinder to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com