Device for cleaning cast-in-place terrazzo polished floor

A floor and clean technology, used in grinding/polishing safety devices, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc. problem, to achieve the effect of concise structure, reduced durability and good driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

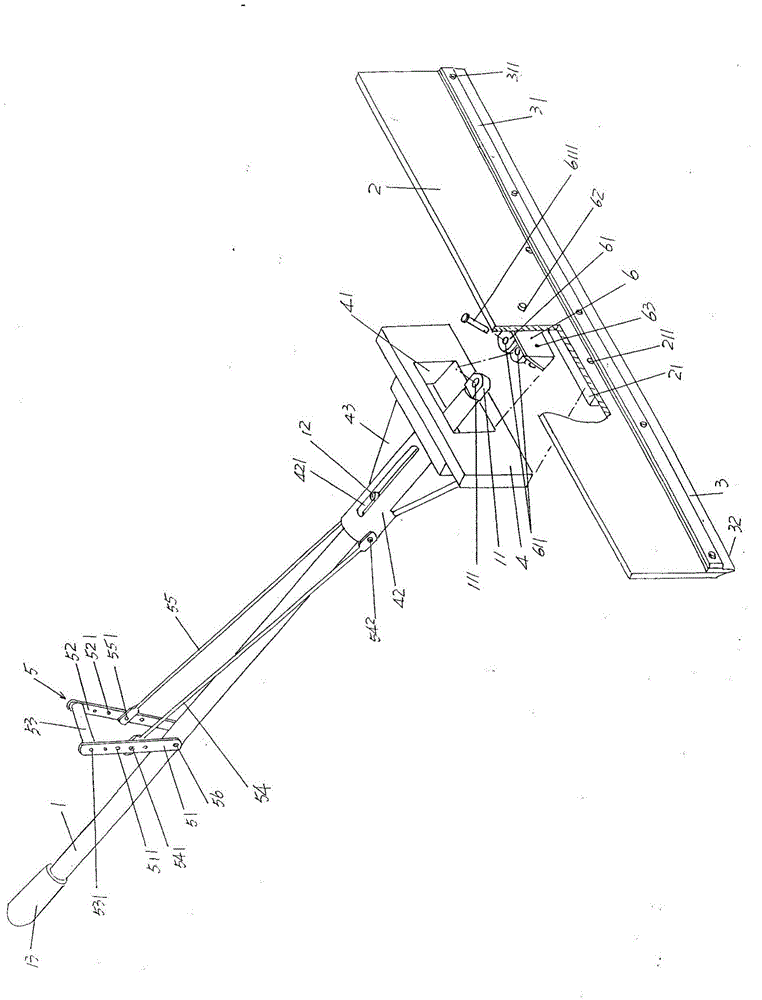

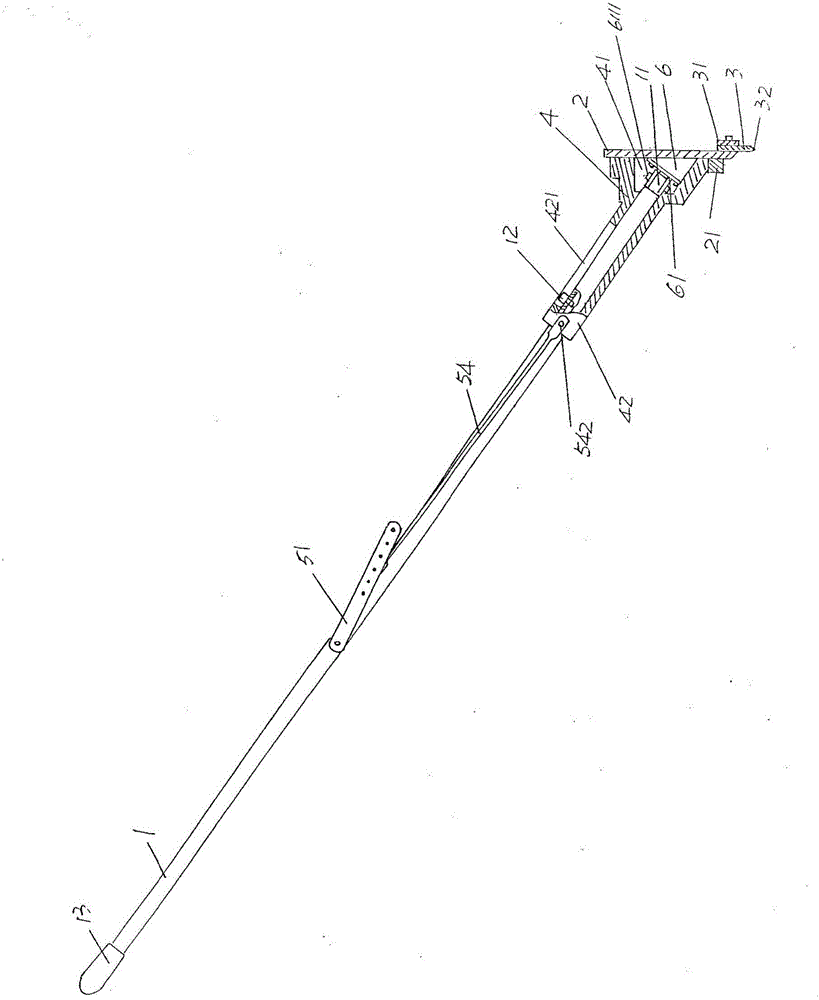

[0023] See figure 1 , in the figure 1 Shown in the figure is a push handle bar 1 and a scraper fixing plate 2 whose material can be metal or non-metal, and a gripping sleeve 13 is set at the end of the push handle bar 1 away from the scraper fixing plate 2, and the scraper The central position of the length direction of the bar fixing plate 2 towards the side of the push bar 1 is hinged with the push bar 1; a scraper 3 is provided, the length of the scraper 3 is equal to the length of the scraper fixing plate 2 and fixed In the lower part of the length direction of the scraper fixing plate 2, the scraper used in this embodiment is a rubber strip; a scraper fixing plate seat 4 for locking or unlocking the aforementioned scraper fixing plate 2 is provided, the The scraper fixing plate seat 4 is slidably sleeved on the push handle bar 1; a mechanism is provided for making the aforementioned scraper fixing plate seat 4 slide on the aforementioned push handle bar 1 so that the scr...

Embodiment 2

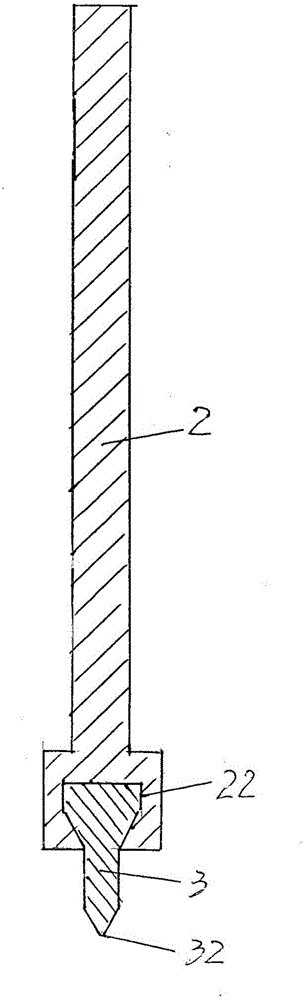

[0036] See figure 2 ,Should figure 2 Another way of fixing the scraper 3 and the scraper fixing plate 2 is shown, specifically: at the bottom of the aforementioned scraper fixing plate 2 in the length direction, there is a hole penetrating from one end of the scraper fixing plate 2 to the other end. A scraper inserting slot 22 , the scraper 3 is inserted into the scraper inserting slot 22 . According to professional common sense, just can replace after scraper 3 wears and tear. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com