Filter element with raw material supply regulator for hydraulic squeezing

A technology of filter elements and regulators, applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

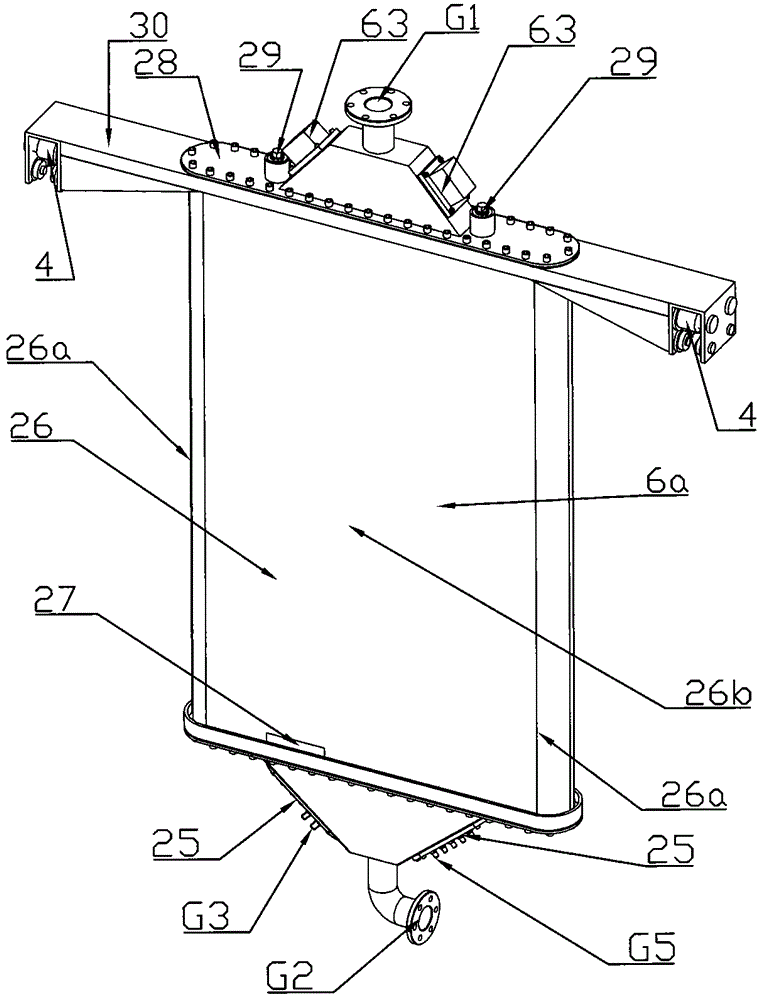

[0070] The filter element of the present invention will be further described below in conjunction with the accompanying drawings.

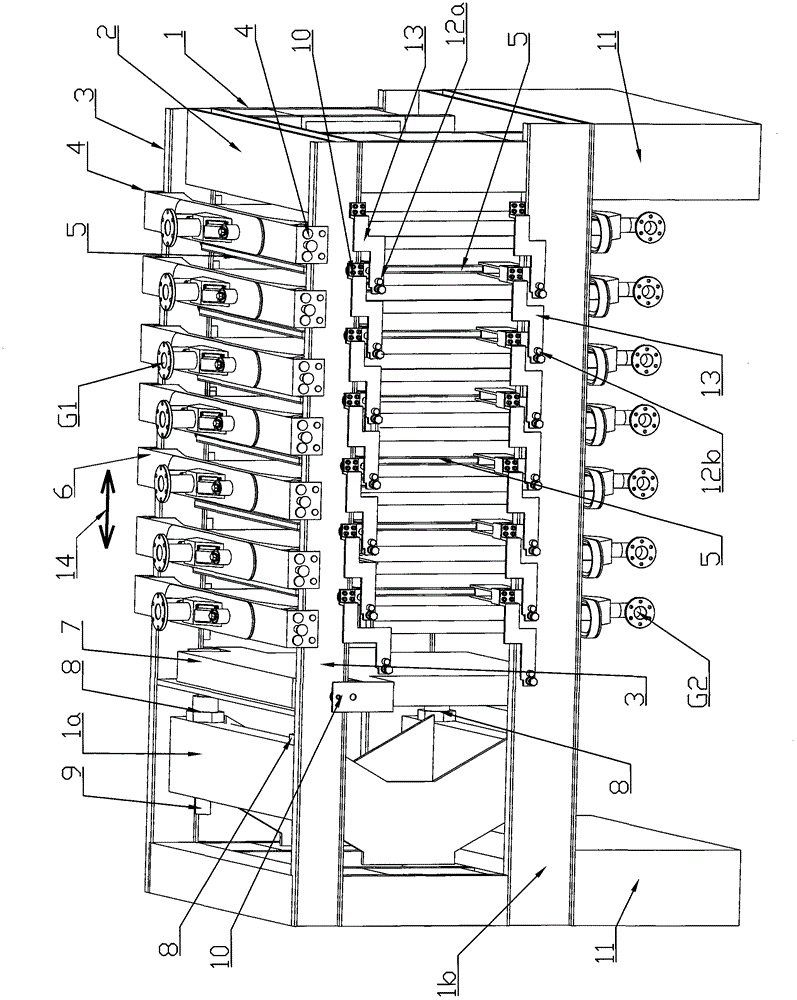

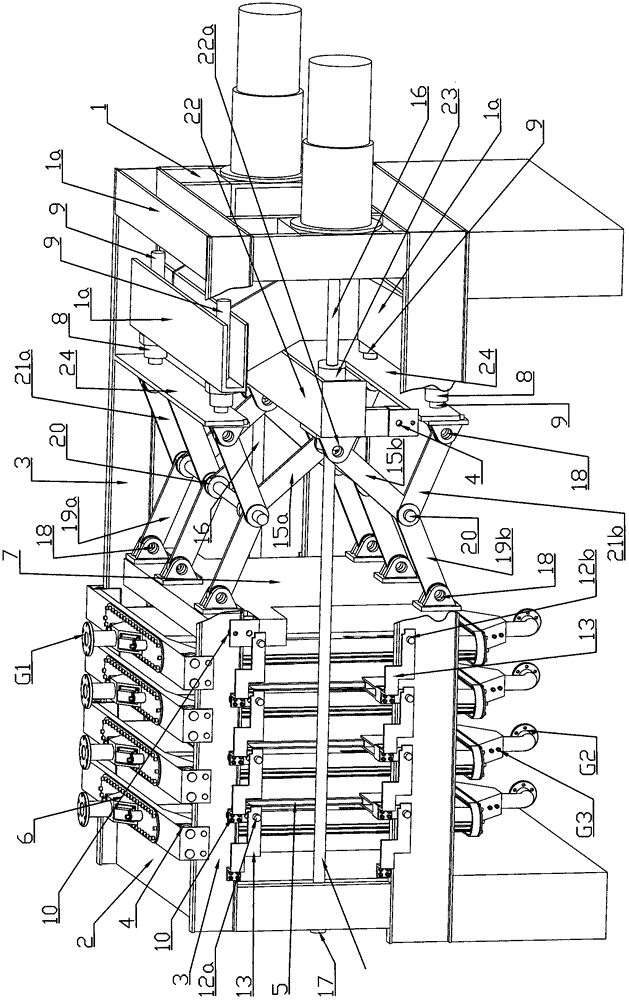

[0071] exist Figures 1 to 15 , 17 and 20, a general embodiment 1 of the filter element of the present invention and its installation in a flexible tube press is shown.

[0072] exist figure 1 The flexible tube press mainly includes pumping device, filter assembly, pressure-bearing device, dry sludge conveying device, filtrate discharge system, pipeline system and control system, and is integrated into a complete set of mechanical and electrical integration automatic solid-liquid separation comprehensive treatment The pressure-bearing device includes a compression assembly and a pressure-bearing structure; the pressure-bearing structure includes a pressure plate 7, a frame guide rail 3, a frame 1 and a pressure-bearing plate, and the pressure-bearing plate includes an intermediate pressure-bearing plate and a final pressure-bearing plate 2; fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com