Automatic Tapping Method of Steel Rolling Heating Furnace

A heating furnace and automatic technology, applied in the field of continuous rolling of steel billets, can solve the problems of low production efficiency, produce quality, and affect the smooth running of production, and achieve the effects of reducing labor intensity of workers, reducing production costs, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

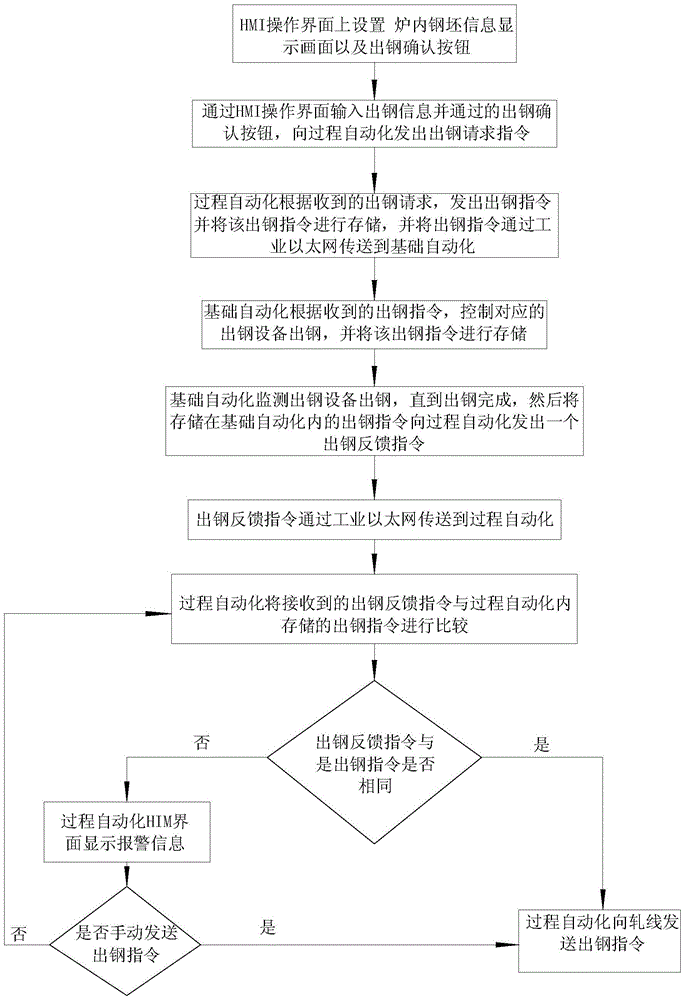

Image

Examples

Embodiment

[0038] A steel factory processes according to the general logic design by adopting the present invention, and the general implementation mode is as follows to design the process automation operation interface;

[0039] 1. Design steel tapping instructions, including furnace number, column number, steel coil number, operation random code, and a natural number with a length of 17 digits. The distribution is as follows: the first digit is the furnace number, the second digit is the furnace row, and the third digit to the No. The thirteenth digit is the steel coil number, and the fourteenth to seventeenth digits are operation random codes. The furnace row is coded with 0, 1, 2, 3 natural numbers; 0 represents long billets, 1 represents short billets near the rolling mill side, 2 represents short billets on the reverse rolling mill side, and 3 represents low billets.

[0040] Design an HMI interface for process automation; the HMI operation interface is provided with a furnace bill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com