Method for recognizing characteristics of bending side of aircraft sheet metal based on topological adjacent performance

A feature recognition, aircraft sheet metal technology, applied in the direction of electrical program control, digital control, etc., can solve problems such as low efficiency and cumbersome process

Active Publication Date: 2015-05-13

SHENYANG AIRCRAFT CORP

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the design of sheet metal parts of various domestic aviation manufacturing enterprises has entered the digital age, but the processing and manufacturing of sheet metal parts is still in the state of the coexistence of CNC machining and traditional technology. It is still necessary to know the key parameters of the flange feature, especially the typical

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

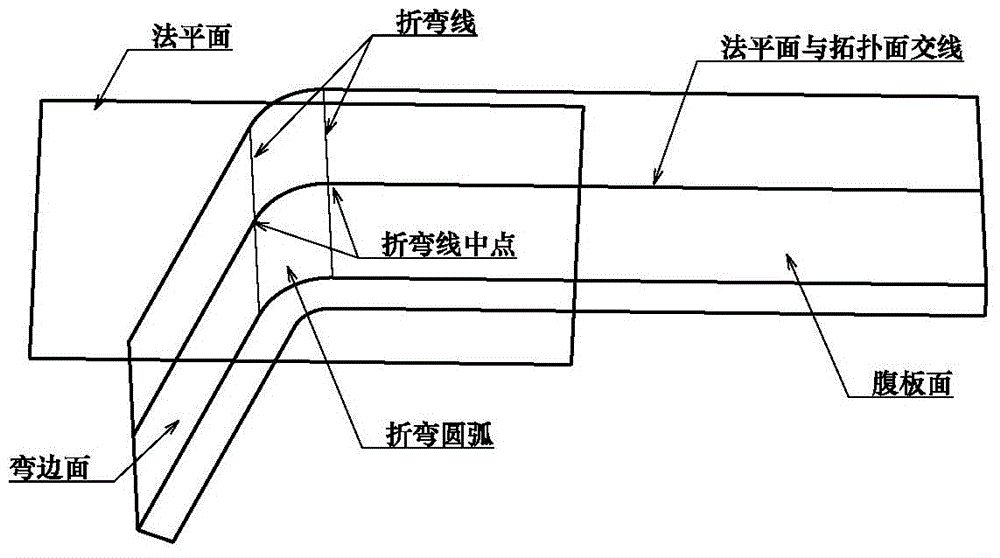

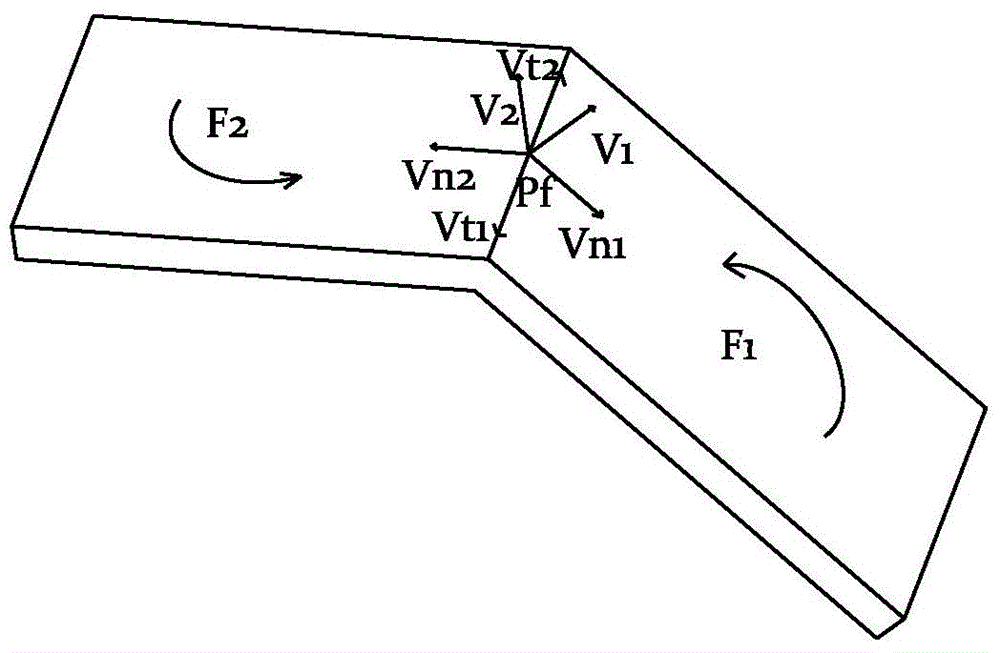

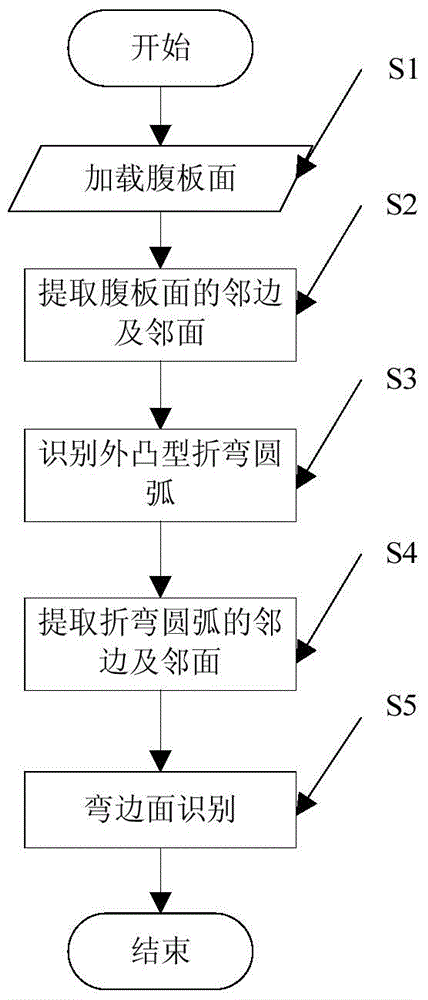

The invention relates to a method for recognizing characteristics of a bending side of aircraft sheet metal based on topological adjacent performance, and belongs to the technical field of digital advanced manufacturing of aircrafts. The method comprises the steps of 1) recognizing topological adjacent performances of two surfaces; 2) classifying and recognizing bending arcs; 3) recognizing bending edge surfaces; the recognizing of the topological adjacent performances of two sides includes (1) defining of the topological adjacent performances of two sides, (2) first-stage classifying and recognizing, and (3) second-stage classifying and recognizing; the classifying and recognizing of bending arc include (1) classifying of the bending arc, and (2) recognizing of the bending arc. According to the method, the two topological surfaces are assumed to be generated by bending an original surface; the common side line of the two topological surface is the bending line, the topological adjacent performance of the two surfaces are defined according to the expression form of the bending line, and therefore, the automatic recognizing of the bending side characteristics can be achieved. With the adoption of the method, the recognizing of the bending side surface can be effectively achieved; the basis is provided for automatically calculating the key parameters of the bending side characteristics surface; therefore, the user interaction workload can be decreased, and the working efficiency can be really increased.

Description

technical field [0001] The invention relates to a method for recognizing a feature of a bending edge of an aircraft sheet metal part. The method can quickly recognize the bending edge features of aircraft sheet metal parts, and belongs to the technical field of aircraft digital advanced manufacturing. Background technique [0002] The bending feature is the bending surface of the aircraft sheet metal part, which is generally the bonding part when connecting with other parts. Due to the complexity of the aircraft structure, the bending feature of the sheet metal part is generally non-planar. [0003] At present, the design of sheet metal parts of various domestic aviation manufacturing enterprises has entered the digital age, but the processing and manufacturing of sheet metal parts is still in the state of the coexistence of CNC machining and traditional technology. It is still necessary to know the key parameters of the flange feature, especially the typical angle, height,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G05B19/19

CPCG05B19/19

Inventor 陈树林方立辉张鑫田世明白玉珍

Owner SHENYANG AIRCRAFT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com