Online detection device and method of battery electrode level in lead-acid storage battery inner chemosynthesis process

A technology for lead-acid batteries and battery electrodes, which is applied in measuring devices, measuring current/voltage, measuring electricity, etc., and can solve problems such as difficulties in measuring battery electrode potentials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

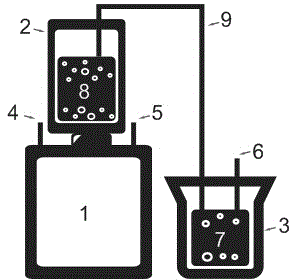

[0015] Specific implementation manner one: such as figure 1 As shown, this embodiment provides an online detection device for battery electrode potential in the internal formation process of a lead-acid battery, which is composed of acid kettle 2, beaker 3, screw A 4, screw B 5, and mercury sulfate electrode C 6. This lead-acid battery is a single cell of the valve-controlled battery. The complete battery consists of several single cells connected in series with a bridge in the middle. Screw A and B are inserted into the bridge, and the edges are sealed with sealant to prevent Acid overflows during the formation process (the positive pole of this cell is also the negative pole of the upper cell, and the negative pole is also the positive pole of the lower cell). The top of the battery is an acid kettle with sulfuric acid solution. The beaker is also filled with sulfuric acid solution. The sulfuric acid system is connected by a salt bridge, and the AC terminal and the BC are resp...

specific Embodiment approach 2

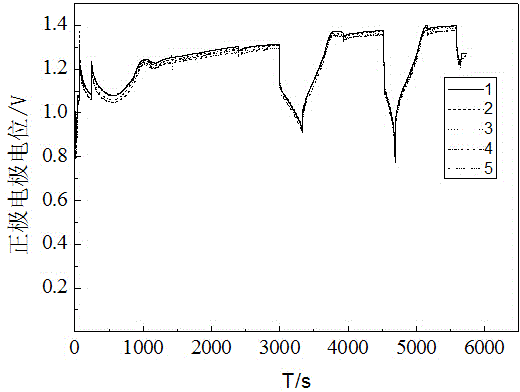

[0019] Specific embodiment 2: This embodiment takes the internal formation process of the 6-DZM-12 battery as an example. The internal formation adopts a three-flush two-discharge formation method. The concentration of the sulfated solution is 1.263g / mL, the temperature is 14℃, The amount of acid injected into the grid is 189g, the concentration of sulfuric acid solution in the beaker is 1.2g / mL, press figure 1 The measuring device diagram measures the electrode potential of the battery. The effect picture is like figure 2 Shown by figure 2 It can be seen that the five electrode potential curves are basically not much different, which can indicate that the difference between the cells formed this time is small and the battery is formed better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com