An intelligent float gas meter

A gas meter and float technology, which is applied in the direction of volume/mass flow generated by mechanical effects, can solve the problems of no temperature and pressure compensation and control valve, the rotating part is delicate and easy to damage, and the structure is complicated, so as to achieve automatic temperature and pressure compensation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

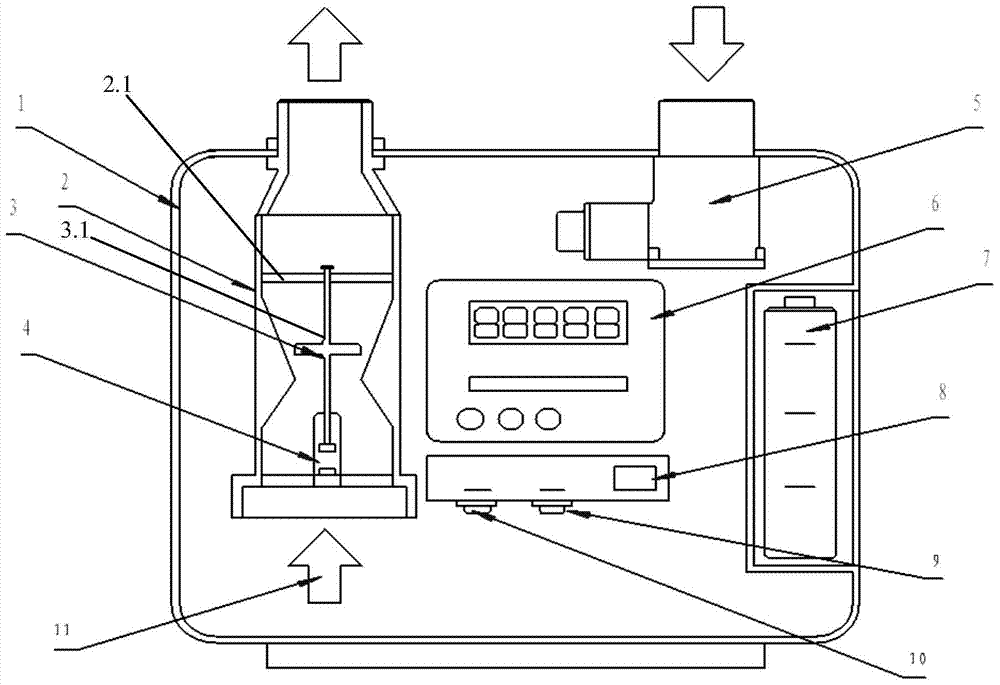

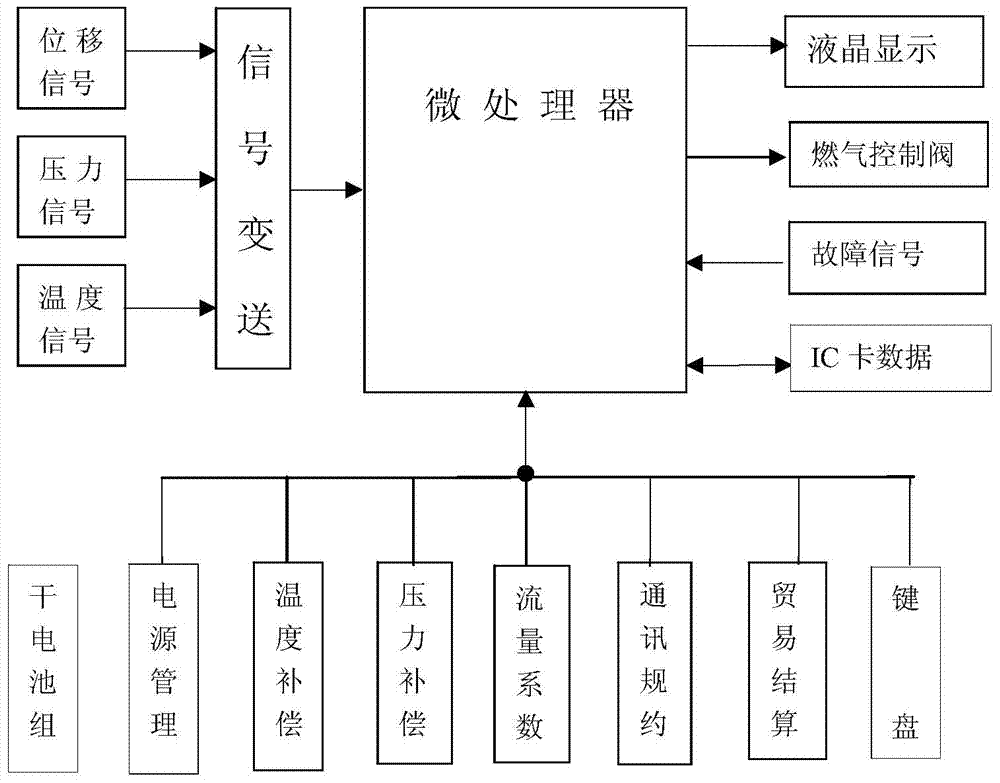

[0020] see figure 1 , the intelligent float gas meter of the present invention includes a housing 1 and a gas control valve 5 arranged in the housing 1, a measuring tube 2 and a microprocessing system 6; the gas control valve 5 guides gas into the housing 1, and the measuring tube The air outlet of 2 protrudes from the outer shell 1, and the tube body of the measuring tube 2 is vertically arranged in the shell 1, and a float 3 is also arranged in the measuring tube 2, and the lower end of the float 3 is connected with a pipe for measuring the float 3 in the measuring tube. 2 Displacement sensor 4 of internal displacement; Inside the shell 1, a temperature sensor 9 and a pressure sensor 10 are also arranged to measure the gas temperature and pressure in the shell 1 respectively; The transmitter is connected with the microprocessor system 6.

[0021] As shown in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com