Lens center thickness measuring device and method based on double face confocal measurement

A lens center and thickness measurement technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of reducing accuracy and achieve the effect of improving accuracy and broadening the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

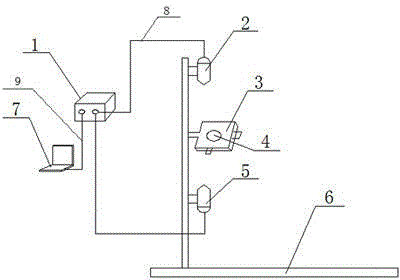

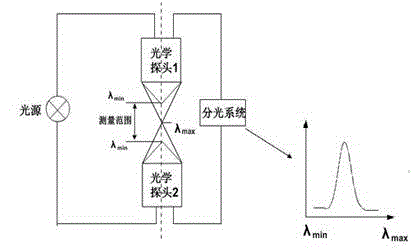

[0017] Such as figure 1 As shown, a lens center thickness measurement device based on double-sided confocal, which includes a controller 1 including a spectrometer, an optical probe I2, a two-dimensional moving frame 3, a lens holder 4, an optical probe II5, a bracket 6 and a computer 7, The optical probe I2, the two-dimensional mobile frame 3 and the optical probe II5 are all fixed on the bracket 6, the lens fixture 4 is mounted on the two-dimensional mobile frame 3, and the controller 1 containing the spectrometer is respectively connected to the optical probe I2 and the optical probe through the optical fiber 8 Ⅱ5 is connected, the optical probe Ⅰ2 and the optical probe Ⅱ5 are set facing each other and the centers of the two optical probes are on the same axis, the two-dimensional mobile frame 3 is located between the two optical probes, and the two-dimensional mobile frame 3 is connected to the two optical probes. The central axis is vertical, and the computer 7 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com