Air-conditioner and control method thereof

A control method and technology for an air conditioner, which are applied in the directions of control input involving air characteristics, space heating and ventilation control input, heating and ventilation control systems, etc. The suction volume and resistance are consistent, and the effect of solving the problem of difficulty in controlling the suction volume of the refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

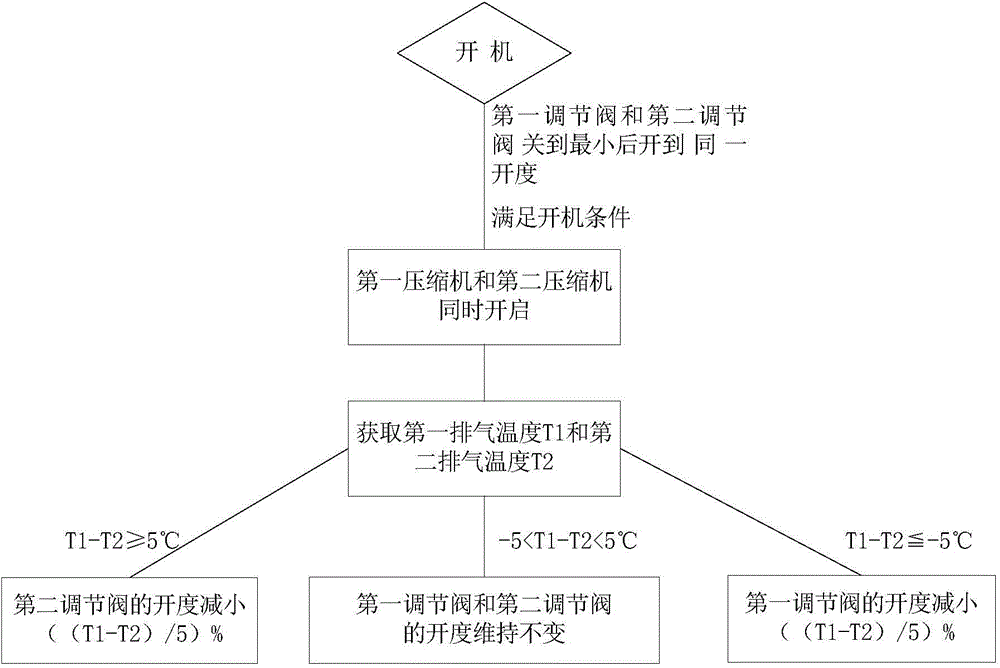

[0044] The difference between the second embodiment and the first embodiment is that when the difference between the first exhaust temperature and the second exhaust temperature is not within the range of the first preset value and the second preset value, the first regulating valve 14 and the second The control modes of the two regulating valves 24 are different, such as image 3 Shown:

[0045] When the first exhaust temperature is greater than the second exhaust temperature, and the difference between the first exhaust temperature and the second exhaust temperature is greater than the first preset value, keep the opening of the second regulating valve 24 unchanged, and increase the A degree of opening of the regulating valve 14 . Specifically, increasing the opening degree of the first regulating valve 14 can reduce the resistance in the first suction pipe 11 . Since the first compressor 10 and the second compressor 20 are arranged in parallel, if the resistance in the se...

Embodiment 3

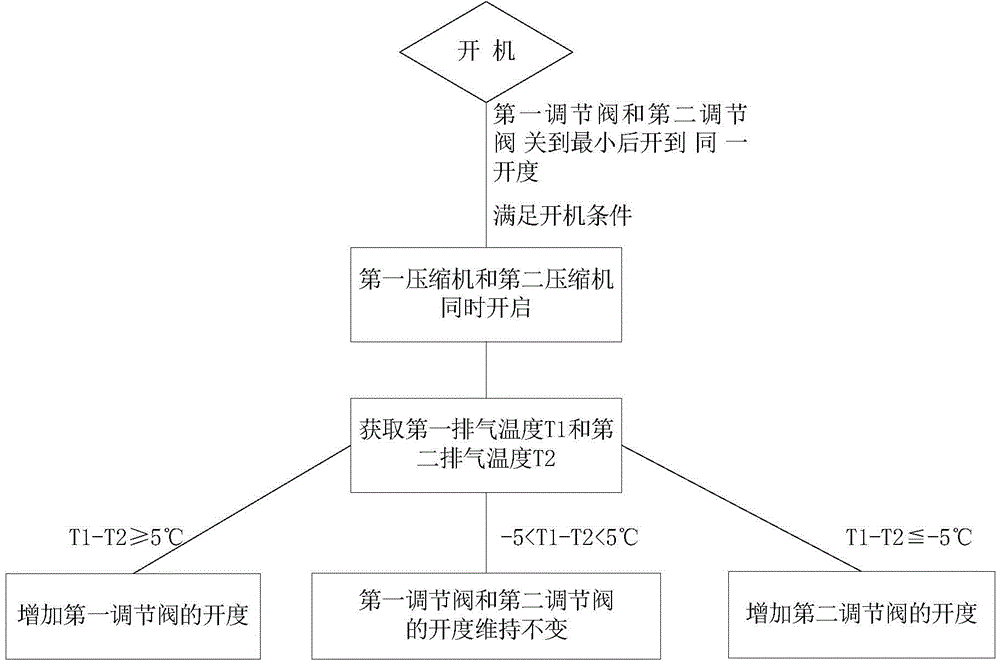

[0048] The difference between the third embodiment and other embodiments is that when the difference between the first exhaust temperature and the second exhaust temperature is not within the range of the first preset value and the second preset value, the first regulating valve 14 and the second The control modes of the two regulating valves 24 are different, such as Figure 4 Shown:

[0049] When the first exhaust temperature is greater than the second exhaust temperature, and the difference between the first exhaust temperature and the second exhaust temperature is greater than the first preset value, increase the opening degree of the first regulating valve 14 and decrease the first Second, adjust the opening degree of the valve 24 , specifically, the above operation makes the resistance in the first suction pipe 11 increase while reducing the resistance in the second suction pipe 21 . Since the first compressor 10 and the second compressor 20 are arranged in parallel, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com