A gasket for a valve of an internal-combustion engine

一种内燃机、衬垫的技术,应用在发动机的密封装置、升阀、阀装置等方向,能够解决发动机效率降低、催化转化器性能降低、阀损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

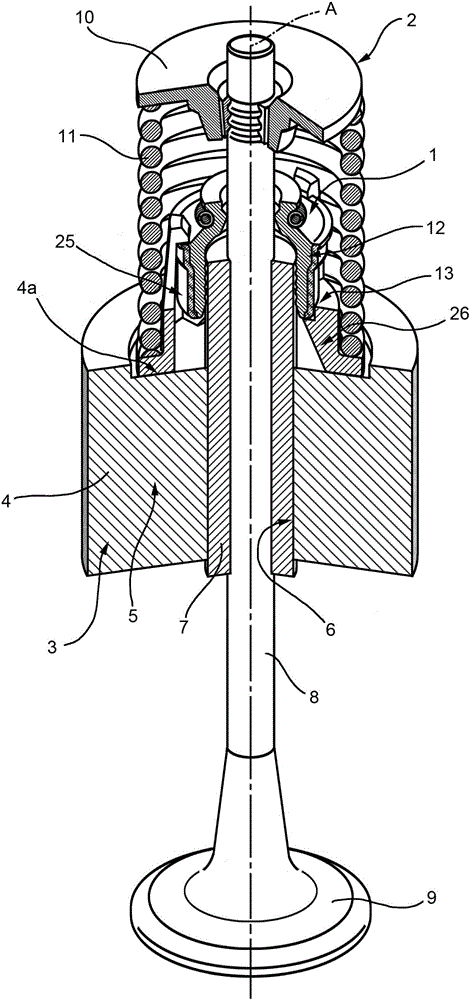

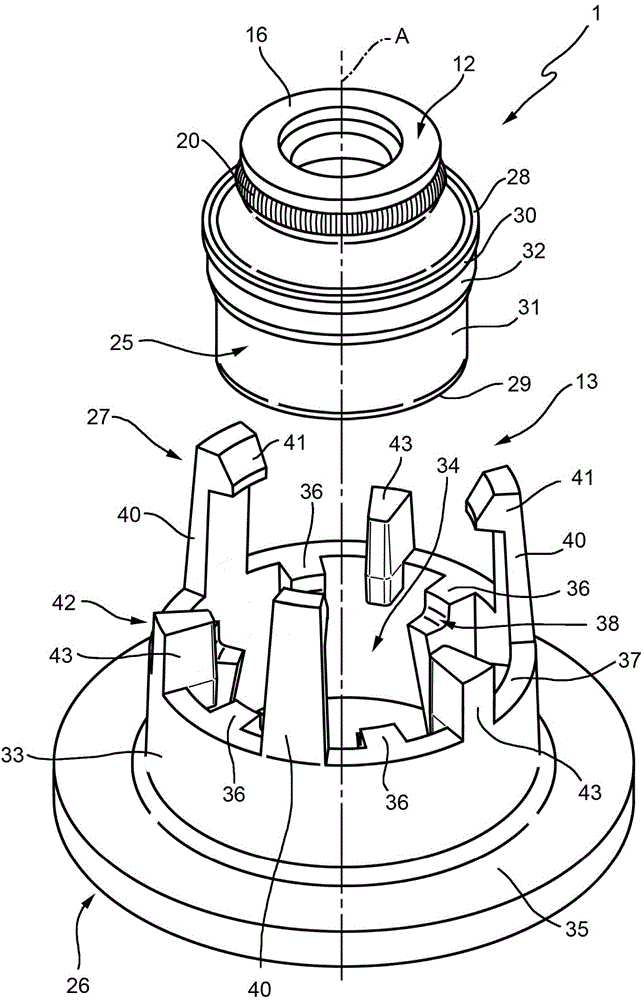

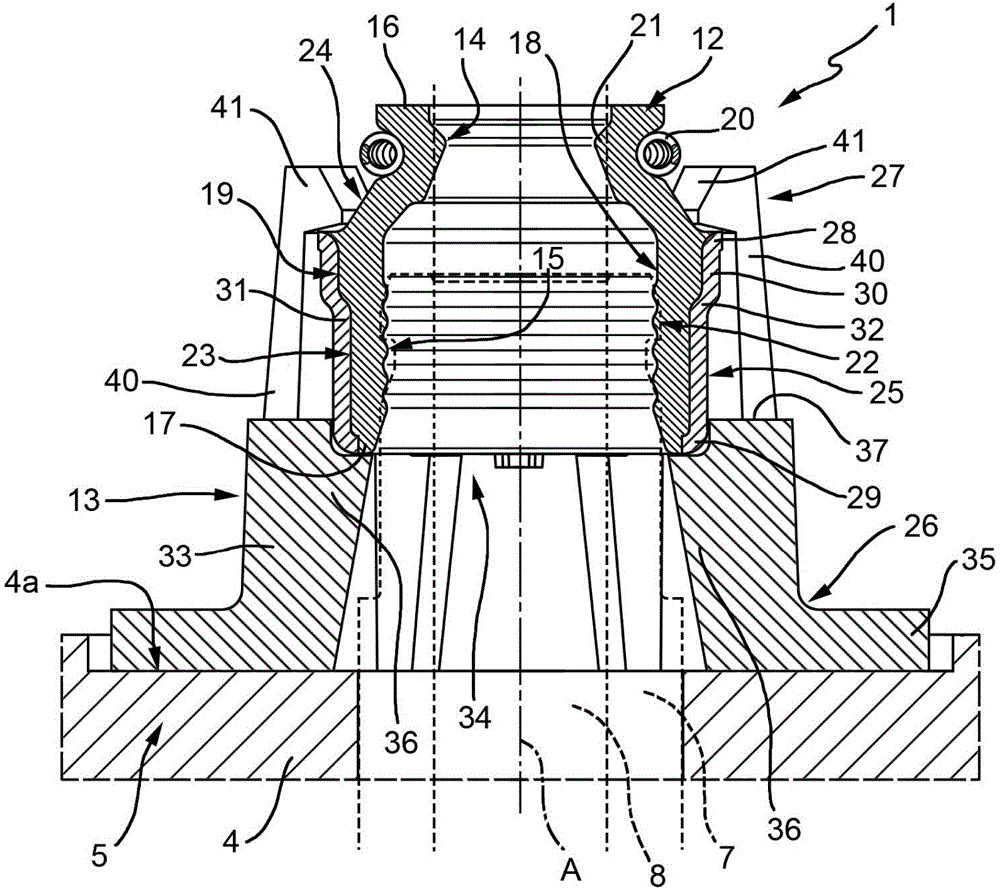

[0029] With reference to the accompanying drawings, indicated as a whole by 1 is a gasket for a valve 2 of an internal combustion engine 3 according to the invention, known in itself and in figure 1 What is shown in is considered to be only necessary for understanding the invention.

[0030] In more detail, in figure 1 In the engine 3 is shown limitedly a portion 4 of a head 5 which in a known manner delimits a combustion chamber (in figure 1 not visible in , but is set below the portion 5 of the head 4 shown), inside the combustion chamber the fuel is oxidized in the presence of combustion air to convert the chemical energy contained in the fuel into Pressure can.

[0031] The combustion chamber receives, in a known manner, through its own opening a mixture comprising fuel and combustion air and, at the end of the combustion process, discharges combusted gases and air through another opening.

[0032] The flow from and to the combustion chamber is controlled by a respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com