An unloadable elastic support device and a method for temporarily supporting loads using it

An elastic support device and elastic support technology, which is applied in the field preparation of pillars and building components, construction, etc., can solve the problems of unrestricted support force, high maintenance cost, poor safety, etc., and achieve simple structure, no damage to the structure, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

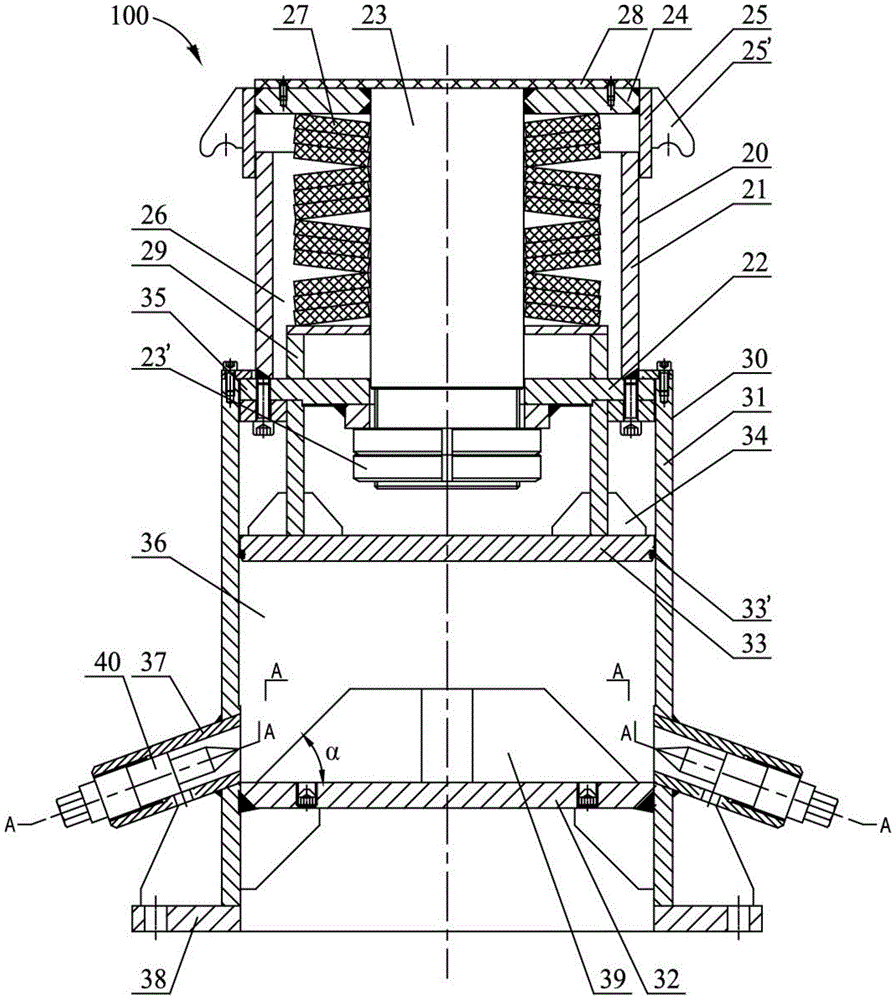

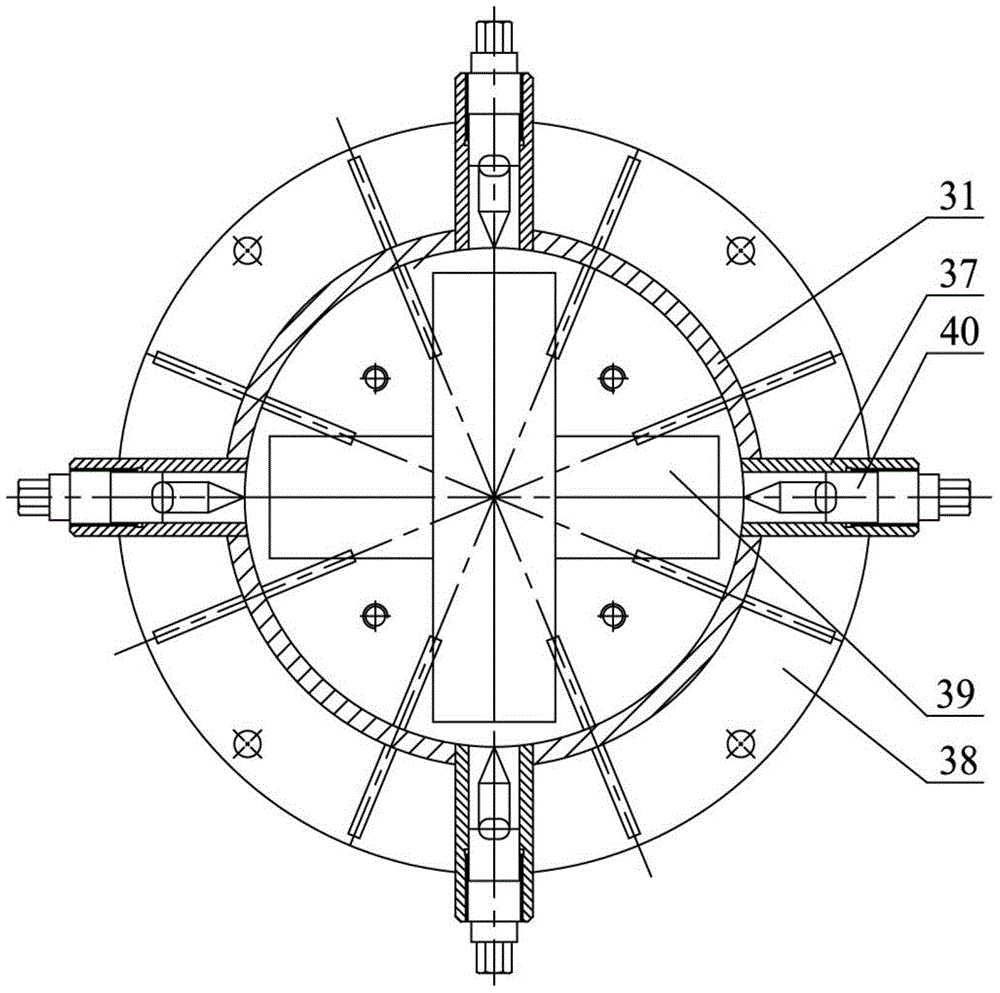

[0027] Example 1: Combining figure 1 and figure 2 Describe the unloadable elastic support device 100 of the present invention, which includes an elastic bracket 20 and an unloading assembly 30 arranged from top to bottom, wherein the elastic bracket 20 is sleeved in the unloading assembly 30 and can be longitudinally arranged along the inner wall of the unloading assembly 30 relative sliding;

[0028] The elastic bracket 20 includes an inner sleeve 21 , a bottom plate 22 fixed on the bottom of the inner sleeve 21 , a mandrel 23 vertically arranged in the inner sleeve 21 , and an upper cover plate fixed on the top of the mandrel 23 . The bottom end of the mandrel 23 passes through the central hole of the bottom plate 22 and is locked by a nut 23 ′. The upper cover plate is formed by connecting the end plate 24 and the outer sleeve 25 , and the outer sleeve 25 is sleeved outside the inner sleeve 21 and can slide relatively along the longitudinal direction of the inner sleeve ...

Embodiment 2

[0039] Embodiment 2: Combination figure 1 and figure 2 Illustrate the method of utilizing the unloadable elastic support device of the present invention to temporarily support loads, and the specific steps are as follows:

[0040] S101: first calculate and determine the maximum load and maximum displacement of the support node, determine the specification, quantity and superimposition mode of the butterfly spring according to the support stiffness, bearing capacity and deformation required by the design, assemble the unloadable elastic support device 100, pass through the sand cylinder 31 Bolt holes 32' on the bottom cover plate 32 are filled with sand bodies into cavity 2 36, and are tightened with bulkhead bolts to close the above bolt holes, and then the disc spring group 27 is pre-compressed and tightened at the bottom of the mandrel 23. Nut 23', the purpose of pre-compressing the disc spring group 27 is to allow the disc spring group 27 to enter the working state (it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com